A cuttings automatic washing machine

A technology for fishing and washing machines and cuttings, applied in the direction of wellbore/well components, earthwork drilling and mining, etc., can solve the problems of harsh working environment, heavy workload, chaotic analysis of geological cuttings, etc., and achieve accurate collection cycle and convenient use Fast and accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

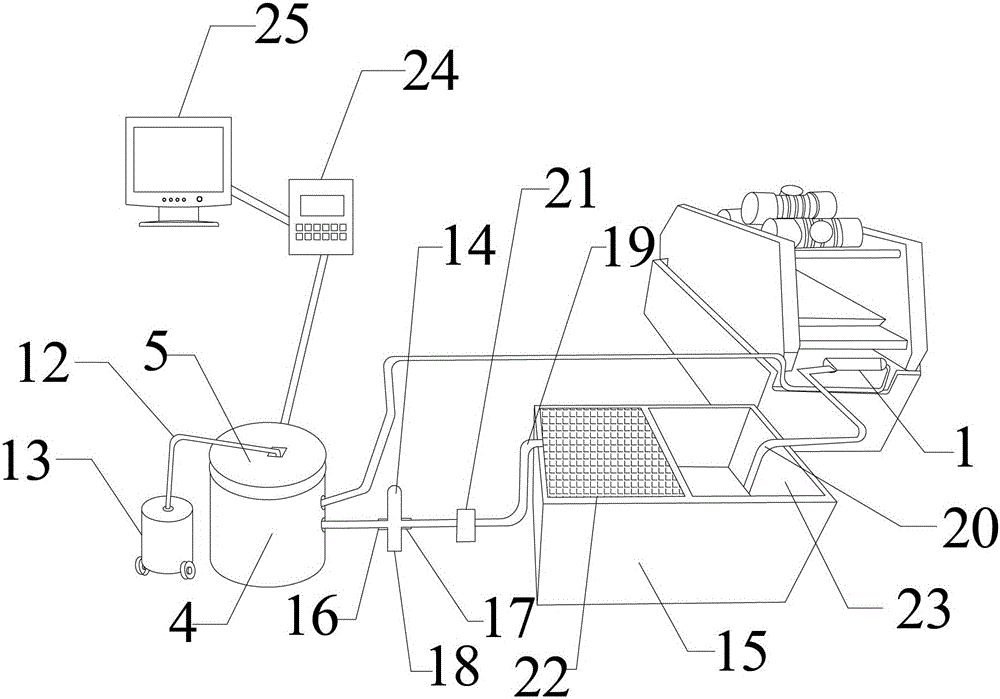

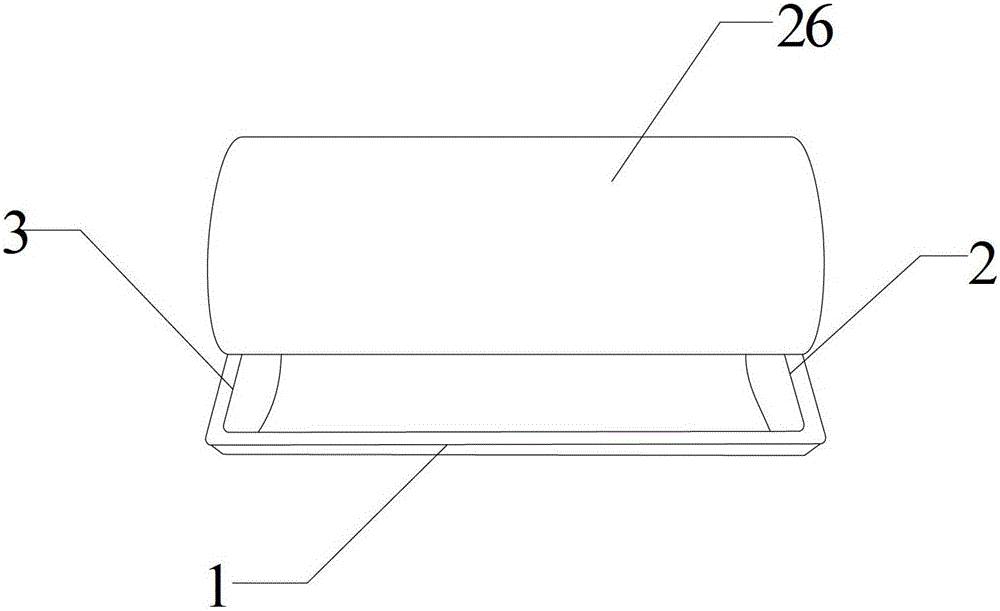

[0018] Example 1, such as Figure 1-3 As shown, a cuttings automatic washing machine includes a collection tank 1;

[0019] The collection tank 1 is used to catch the rock debris falling from the vibrating screen, and the collection tank 1 is respectively provided with a first water inlet 2 and a first water outlet 3;

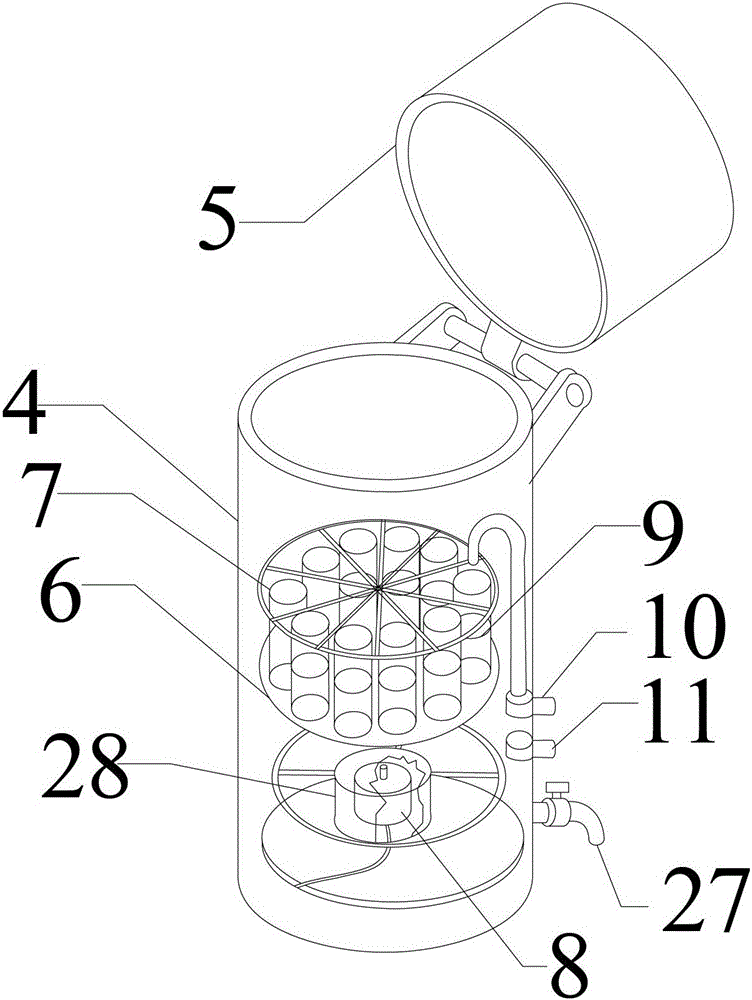

[0020] The first water outlet 3 is connected with a storage cylinder 4, the top of the storage cylinder 4 is provided with a storage cylinder cover 5, the bottom of the storage cylinder 4 is sealed, and the storage cylinder 4 is provided with a turntable 6, and a plurality of sand storage tanks 7 are arranged on the turntable 6 A stepper motor 8 is provided on the side of the turntable 6 away from the sand storage tank 7, a screen 9 is provided inside the sand storage tank 7, and a second water inlet 10 and a second water outlet 11 are respectively provided on the side wall of the storage cylinder 4. , the second water inlet 10 is connected with the first wate...

Embodiment 2

[0025] Example 2, such as Figure 1-3 As shown, a cuttings automatic washing machine includes a collection tank 1;

[0026] The collection tank 1 is used to catch the rock debris falling from the vibrating screen, and the collection tank 1 is respectively provided with a first water inlet 2 and a first water outlet 3;

[0027] The first water outlet 3 is connected with a storage cylinder 4, the top of the storage cylinder 4 is provided with a storage cylinder cover 5, the bottom of the storage cylinder 4 is sealed, and the storage cylinder 4 is provided with a turntable 6, and a plurality of sand storage tanks 7 are arranged on the turntable 6 A stepper motor 8 is provided on the side of the turntable 6 away from the sand storage tank 7, a screen 9 is provided inside the sand storage tank 7, and a second water inlet 10 and a second water outlet 11 are respectively provided on the side wall of the storage cylinder 4. , the second water inlet 10 is connected with the first wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com