Underground mine soft rock roadway ground pressure safety early warning monitoring method

A technology for safety early warning and roadway, applied in mining equipment, mining equipment, earthwork drilling and other directions, can solve the problems of single ground pressure monitoring system, remote transmission and processing of data collected on site, unstable monitoring data, etc., and achieve remarkable results. , Improve the early warning ability, and facilitate the organization and implementation of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

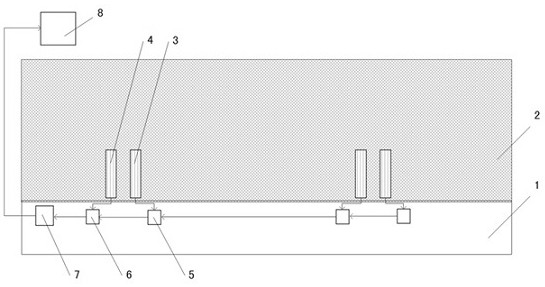

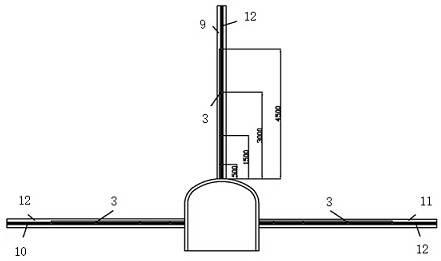

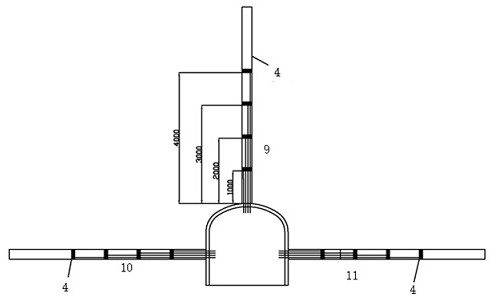

[0028] (1) The first step is to determine the location of the monitoring roadway. The -230m level of an iron mine is the middle section of the first mining, which is extremely critical to safe production. Therefore, a typical section is selected to install ground pressure monitoring equipment in the -230m level footwall roadway along the vein. A total of 5 areas were selected, and the section of the roadway was about 4.8 m × 3.85 m. The ground pressure monitoring was mainly based on stress and deformation monitoring. The ground pressure monitoring equipment used anchor stress gauges and multi-point displacement gauges.

[0029] (2) The second step is to monitor the surrounding rock pressure of the roadway and analyze the data. Anchor rods or anchor cable stress gauges are used for roadway surrounding rock pressure monitoring, and a group is arranged every 20 meters along the direction of the roadway to continuously observe the pressure load changes of the roadway surrounding r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com