Gob-side entry retaining flexible infilled wall body structure and filling method thereof

A technology of wall structure and roadway retention, which is applied in the direction of filling, earthwork drilling, safety devices, etc., can solve the problems of gas leakage, complicated process, deformation of surrounding rock, etc. in the support body, and achieve the prevention of lateral deviation, The effect of overcoming polluted environment and inhibiting subsidence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

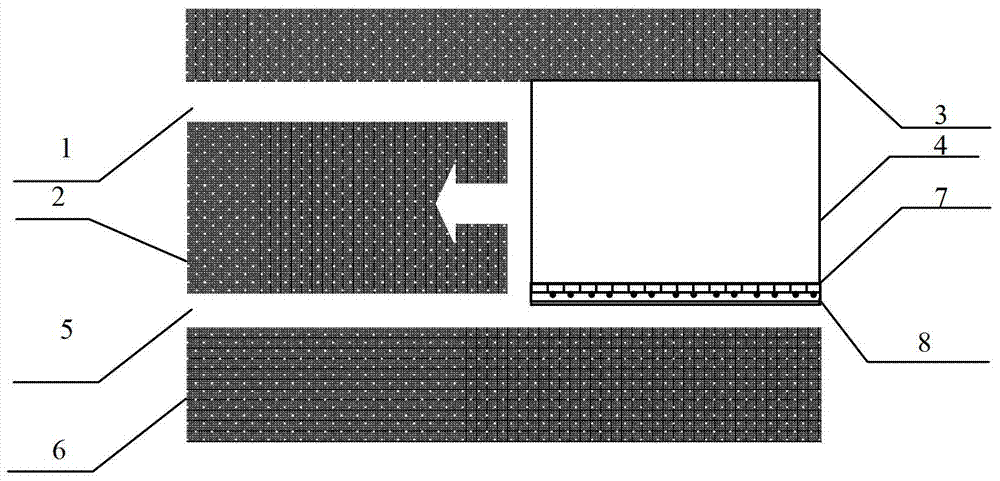

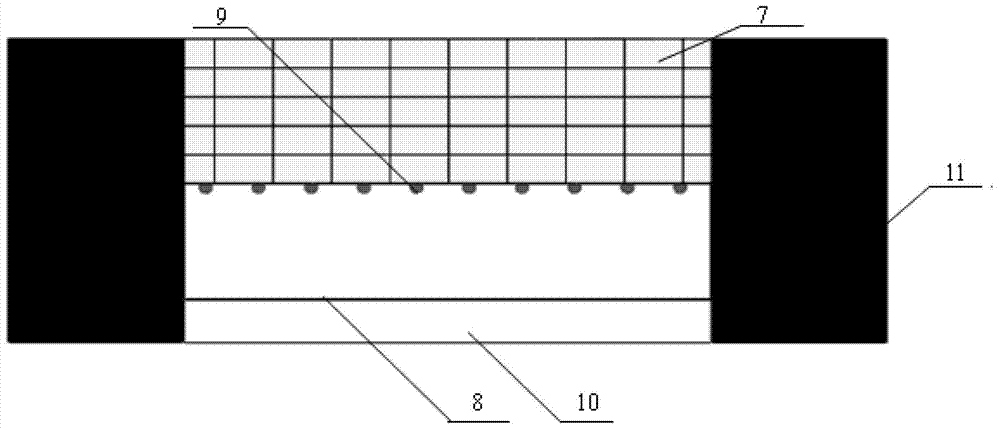

[0039] Such as Figure 1-Figure 5As shown, the gobside retaining flexible filling wall structure of the present invention includes a filling wall 8 and bagged gangue 7 and threaded anchor rods 9 arranged inside the filling wall 8 . The filling wall is located in the goaf 4 of the working face between the air return roadway 1 and the transportation roadway 5, which is close to the transportation roadway 5, and the roadway between the coal body 3 on the upper working face and the coal body 2 on the working face is the return airway. Air lane 1, the roadway between the coal body 6 of the lower working face and the coal body 2 of this working face is the transport lane 5. There are multiple bagged gangue 7 and threaded anchor rods 9, the laying height of the bagged gangue 7 is the height of the roadway, and the threaded anchor rod 9 is in contact with the bagged gangue 7 on the side of the roadway near the transportation lane 5 And vertically buried in the roadway floor 11.

Embodiment 2

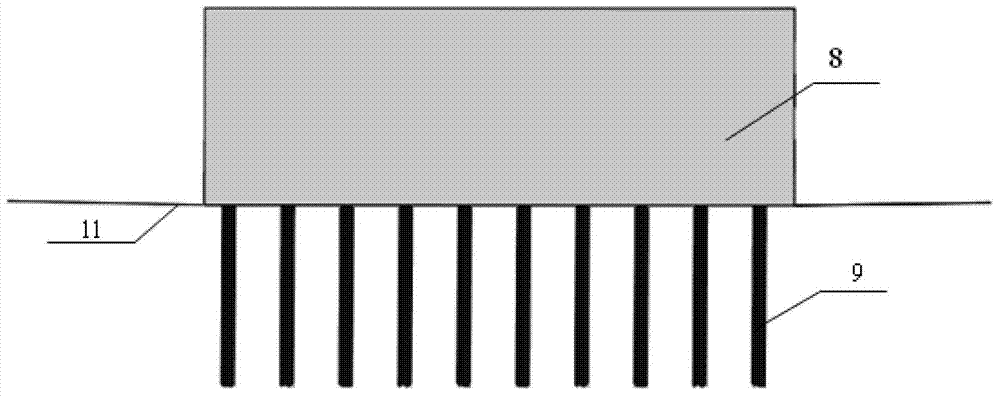

[0041] On the basis of Example 1, the size of a single bagged gangue 7 is length*width*height=450mm*450mm*150mm, and the gangue particle diameter inside it is less than 20mm; the exposed part of the threaded anchor rod is 800mm long. -1200mm; the distance between the plurality of threaded anchor rods 9 is 450mm, and each of the threaded anchor rods is just in the middle of each bottom bagged gangue; the distance between the bagged gangue on the side of the transportation lane 5 is 7 A filling wall formwork 10 is erected at a distance of 500-750 mm; the filling wall 8 includes sand, cement, and coal mine special filling quick-setting curing cement powder.

[0042] The laying width of the bagged gangue 7 is determined by the force balance formula of the lateral overlying rock structure model, namely:

[0043] W = 4 L m + 4 R q - ...

Embodiment 3

[0051] A method for flexible wall filling in gob-side retaining, comprising the following steps:

[0052] (1) Firstly, the underground gangue is directly transported to the underground crushing chamber through the belt conveyor and crushed to form gangue with a suitable particle size of less than 20mm, and the formed gangue is loaded into a box whose size is length*width*height=450mm*450mm*150mm in a woven bag;

[0053] (2) Pile up bagged gangue 7 along the goaf, lay interlaced filling between each layer for roadside support, and form a preliminary filling wall skeleton;

[0054] (3) After the above steps are completed, a row of threaded anchor rods 9 through the wall are drilled at the side of the roadway side of the bagged gangue 7 near the transport lane 5. The exposed part of the threaded anchor rods is 800-1200mm in length, and two adjacent The distance between the threaded anchor rods 9 is 450mm, and each of the threaded anchor rods is just in the middle of each bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com