Double heat source vertical reactor

A vertical reactor, dual heat source technology, applied in chemical/physical/physical-chemical fixed reactors, chemical/physical/physical-chemical processes, chemical instruments and methods, etc. It is easy to cause problems such as precipitation, so as to improve the anti-sedimentation effect, promote water circulation and prevent precipitation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

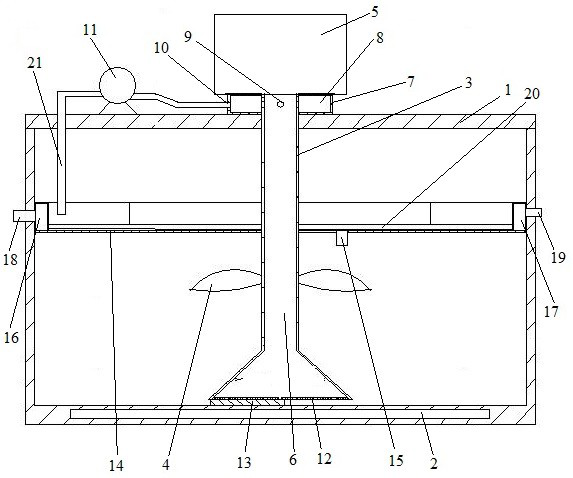

[0019] Embodiment one, see figure 1 , a vertical reaction kettle with dual heat sources, comprising a kettle body 1 and an agitator for stirring materials stored in the kettle body. The kettle body is provided with an electric heater 2 at the bottom of the kettle body. The stirrer comprises a vertical shaft 3, a vertical shaft stirring blade 4 connected to the vertical shaft and a stirring motor 5 that drives the vertical shaft to rotate, and the stirring motor is arranged vertically. A pumping channel 6 is provided in the vertical shaft, and the upper end of the vertical shaft is rotatably installed in the liquid outlet ring 7, and the inner peripheral surface of the liquid outlet ring is provided with an annular groove 8 extending circumferentially along the vertical shaft. The vertical shaft seals the opening of the annular groove, and the peripheral surface of the vertical shaft is provided with a number of connecting holes 9 on the vertical shaft connecting the annular g...

Embodiment 2

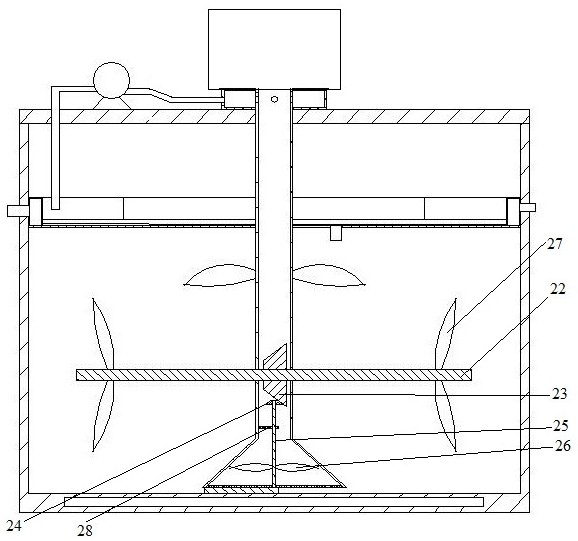

[0021] Embodiment two, the difference with embodiment one is:

[0022] see figure 2 , the vertical rotation shaft is connected with a horizontal rotation shaft 22, the horizontal rotation shaft is connected with a driven bevel gear 23 located in the pumping channel, the driven bevel gear is meshed with a driving bevel gear 24, and the driving bevel gear is connected with a The vertical rotating shaft 25 in the liquid pumping channel is fixedly connected with the driving blade 26 driven by the liquid flow flowing through the liquid pumping channel and rotates around the vertical rotating shaft, and the horizontal rotating shaft is connected with a horizontal rotating shaft stirring Blade 27. Two horizontal rotation shafts are located on a straight line, and the two horizontal rotation shafts located on the same straight line are driven by the same driven bevel gear. Suspension block 28 is arranged in the pumping channel, and the vertical rotating shaft is rotatably connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com