Plate heat exchanger

A plate heat exchanger, heat exchanger technology, applied in the direction of heat exchanger type, indirect heat exchanger, heat exchange equipment, etc. Good safety and reliability performance, the effect of avoiding high-risk temperature differential stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

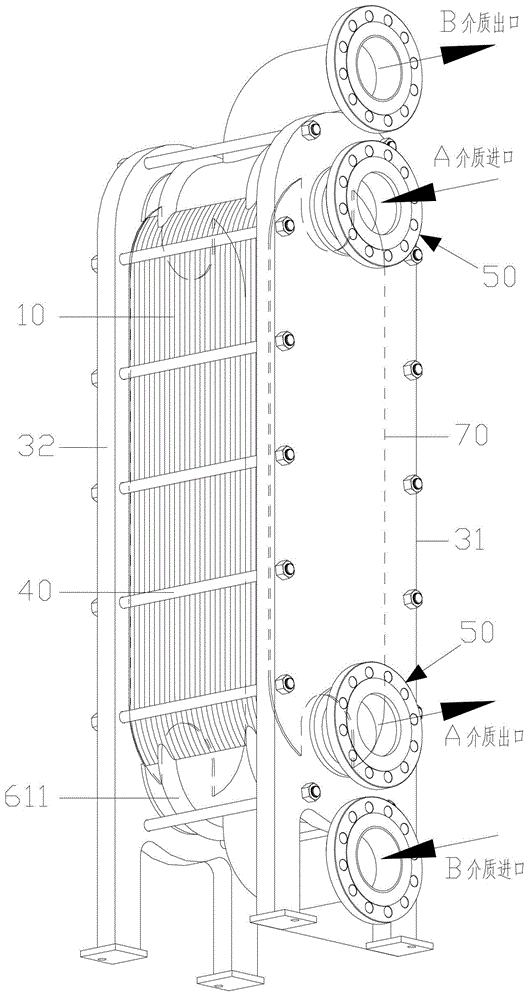

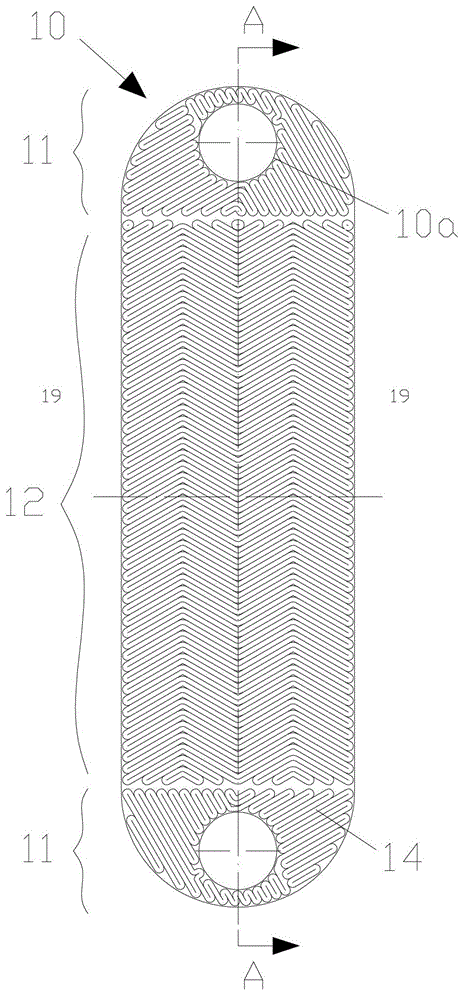

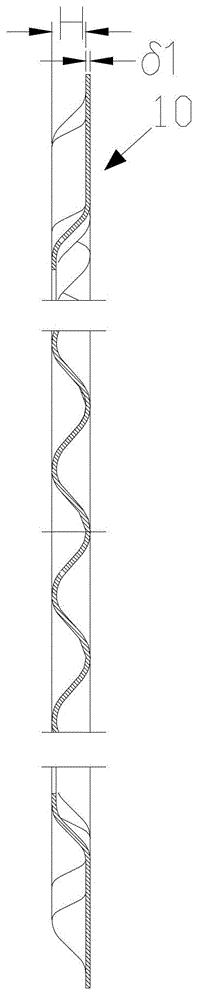

[0027] A plate heat exchanger, including a number of heat exchange plates 10 with through holes 10a stacked to form a heat exchange matrix, and the adjacent heat exchange plates 10 are formed between the abutting surfaces for the flow guide medium The flow guide channel 20 and the through hole 10a on the heat exchange plate 10 are arranged coaxially to form a liquid inlet and outlet hole connected to external equipment, and the front and rear end plates 31 for clamping the heat exchange base are respectively arranged at the front and rear end faces of the heat exchange base , 32, the front and rear end plates 31, 32 are provided with a heat exchange channel 33 that runs through the plate body and is used to coaxially cooperate with the liquid inlet and outlet holes on the heat exchange base. Connect the front and rear end plates 31, 32 and form a rigid fit tie rod 40 between the front and rear end plates 31, 32 and the heat exchange base; The gap where the heat exchange substr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com