Auxiliary compression tool for thin plate material and application method thereof

A technology of auxiliary tools and thin plate materials, applied in the direction of analyzing materials, instruments, measuring devices, etc., can solve problems such as compression bending instability, achieve the effect of increasing reduction, ensuring stability, and reducing size requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

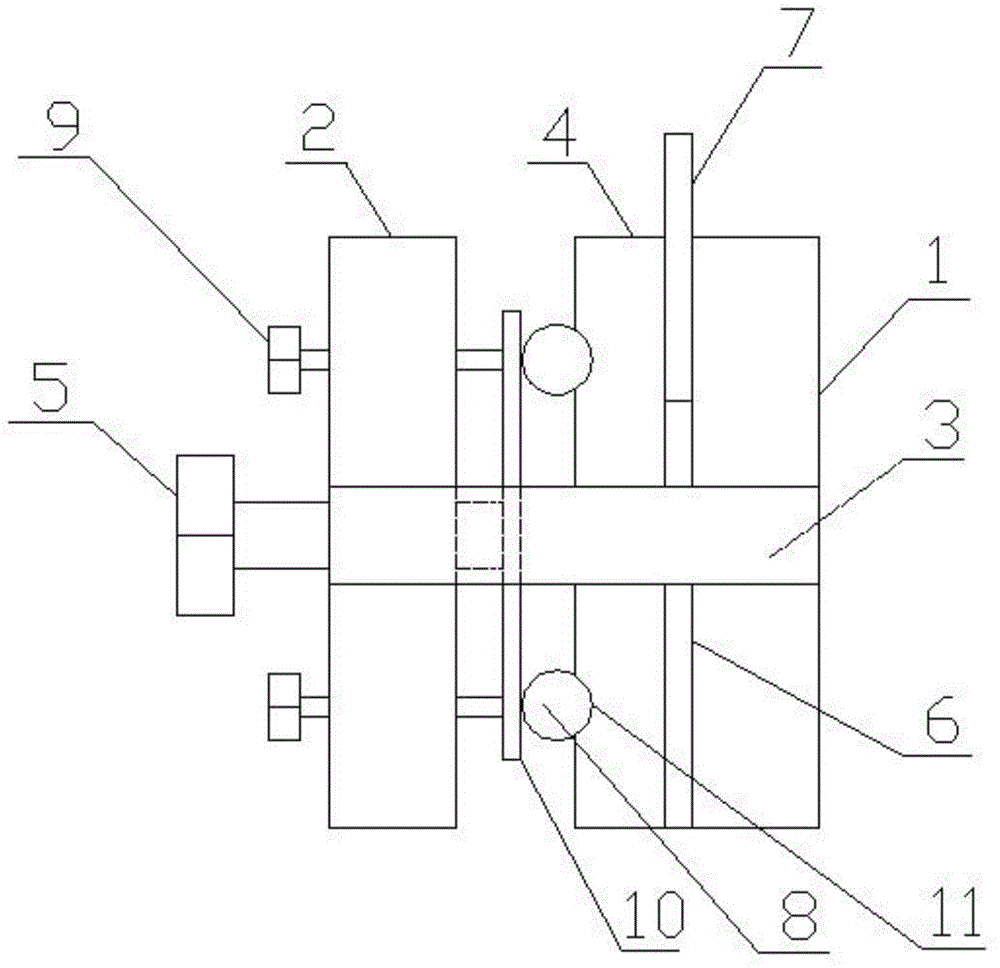

[0012] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0013] As shown in the figure, a thin plate material compression aid tool of the present invention includes a splint 1 and a fixing plate 2. A connecting plate 3 is provided between the splint 1 and the fixing plate 2, and a connecting plate 3 is provided between the splint 1 and the fixing plate 2. There is a pressing plate 4, and the fixing plate 2 is provided with a fastening bolt 5 for pressing the pressing plate 4 against the clamping plate 1, and a pressing head 7 for pressing the test sample 6 is arranged between the pressing plate 4 and the clamping plate 1. Place the test sample 6 and the indenter 7 between the clamping plate 1 and the pressure plate 4, rotate the fastening bolt 5, fix the test sample 6 and the indenter 7, and press the test sample 6 through the indenter 7 to complete the test.

[0014] In this embodiment, a plurality...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com