Method for measuring microhardness of curved surface

A technology of microhardness and curved surface measurement, applied in the direction of testing material hardness, etc., can solve problems such as inability to meet measurement requirements and inconvenience, and achieve the effect of simple and reliable measurement method, convenient measurement and small error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

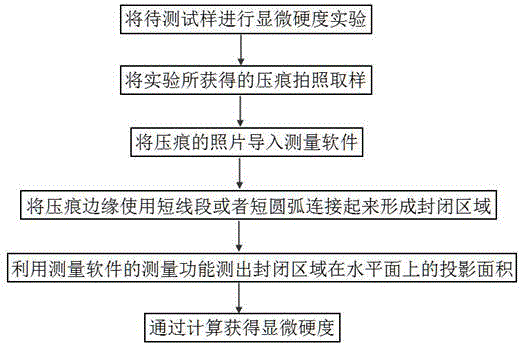

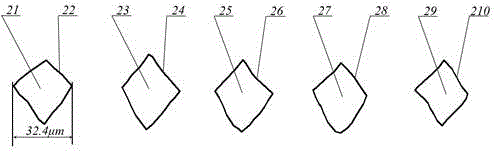

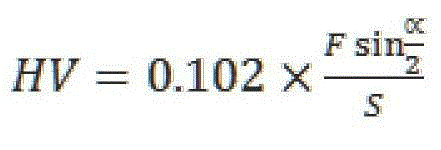

[0020] In order to better explain the implementation details of the present invention, and to compare the accuracy of the measurement results, a method for measuring the microhardness of curved surfaces according to the present invention will be described in detail below in conjunction with the accompanying drawings.

[0021] Take the measurement of the microhardness of two different samples as an example. Both samples are made of LY2 aluminum alloy. The surface to be tested of sample 1 is flat, and the surface to be tested of sample 2 is an irregular curved surface. Both samples are polished after undergoing the same heat treatment process. Processing, therefore, the microhardness of the two specimens is the same.

[0022] The microhardness tester used for the measurement is HXD-1000TMSC / LCD hardness tester, which can take pictures of the samples to be tested. First, the microhardness of sample 1 was measured by conventional methods. The load used in the test was 100 grams, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com