Dynamic scheduling method and system of cigarette flexible cut tobacco production

A dynamic scheduling and flexible technology, applied in the fields of tobacco, tobacco preparation, comprehensive factory control, etc., can solve problems such as difficult efficient control of cigarette shred production, and difficult for planning departments to formulate efficient production plans, so as to achieve easy deployment , high flexibility and adaptability, simple system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the examples, but the present invention is not limited in any way, and any changes or improvements made based on the teaching of the present invention belong to the protection scope of the present invention.

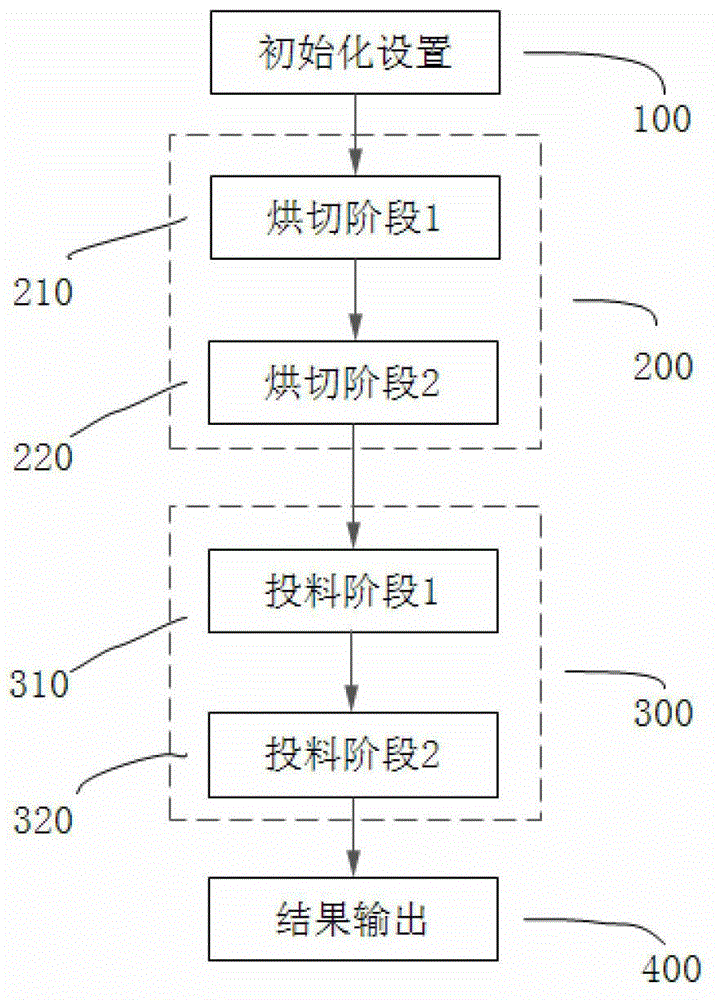

[0023] Such as figure 1 As shown, a dynamic scheduling method for cigarette flexible shred production according to the present invention includes the steps of initialization setting, cutting and drying scheduling, feeding scheduling, and result output, specifically including:

[0024] A. Initialization settings: set and / or read the initial volume of the system and information on modules, shifts, and batches;

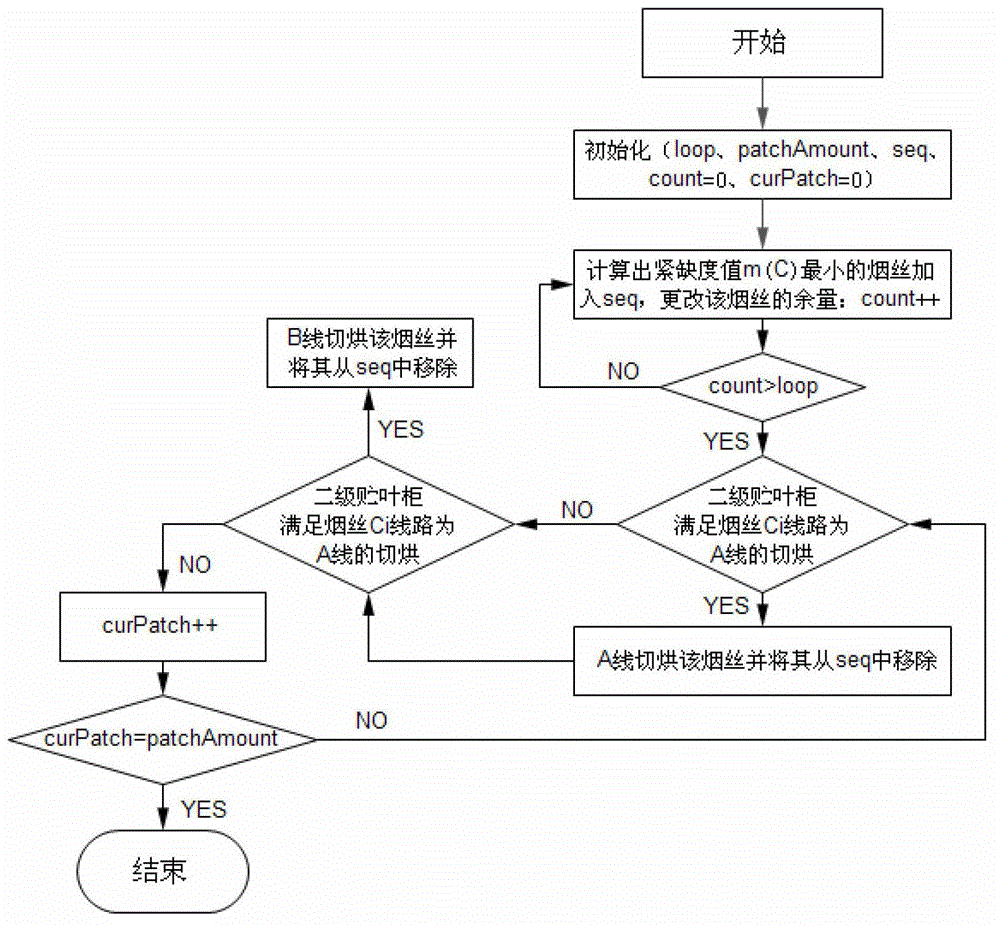

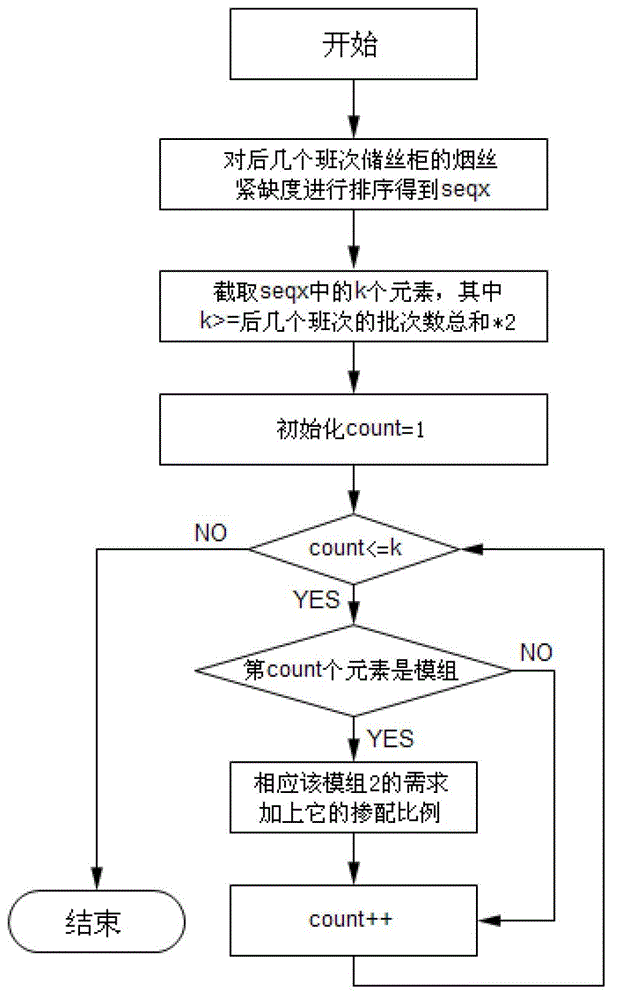

[0025] B. Cutting and drying scheduling: Calculate the demand and shortage degree of the cigarette machine for the wire storage cabinet and / or wire distribution cabinet, sort the wire storage cabinet and / or wire distribution cabinet according to the shortage value of cut tobacco and ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com