Centralized scheduling method based on distributed terminal

A centralized scheduling and distributed technology, applied in the field of metering systems, can solve problems such as inconsistent personnel business levels, gaps in personnel labor intensity, and many weighing vehicles, and achieve the effect of improving the staff's business level, improving the efficiency of weighing, and improving the level of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

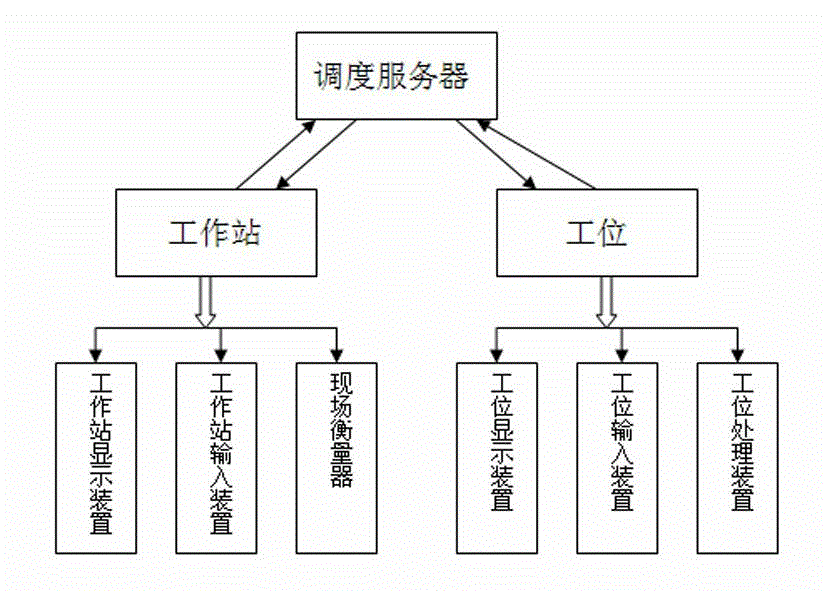

[0013] Connect each workstation, station, and scheduling server through a communication network. The workstation includes a field scale, a workstation display device, and a workstation input device. The workstation includes a workstation display device, a workstation input device, and a workstation processing device;

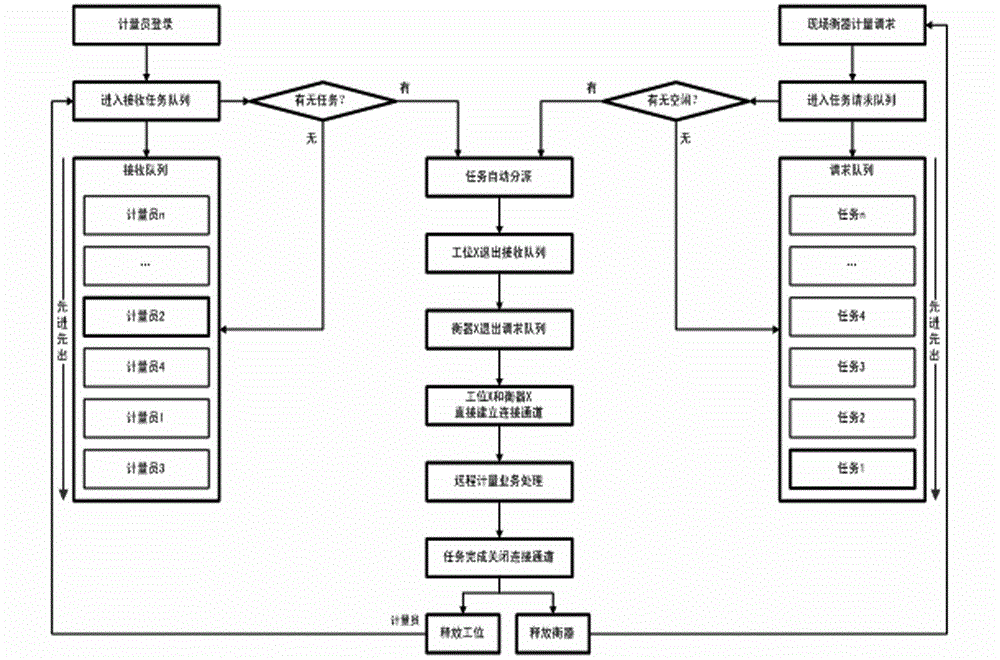

[0014] When the station needs to be measured, the staff of the station input the relevant information into the station input device, and the station input device transmits the information to the dispatching server through the station processing device, and the dispatching server receives the measurement request information sent by the station, Query the working status of the on-site measuring device at the workstation. If there is an idle on-site measuring device, according to the computing power of the workstation, the information that needs to be measured at each station will be allocated to each station in the idle state according to the principle of "first in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com