Dry quenching primary dust removal cooling system leakage detection system and diagnosis method

A technology of cooling system and leak detection, which is applied in the direction of measuring the increase and decrease rate of fluid, and liquid tightness measurement by using liquid/vacuum degree, etc., which can solve the problems of increased concentration of combustible components, economic loss, low level of coke powder, etc. problem, to achieve the effect of improving accuracy and timeliness, improving management and control level, and timely operation response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0100] The specific embodiments provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

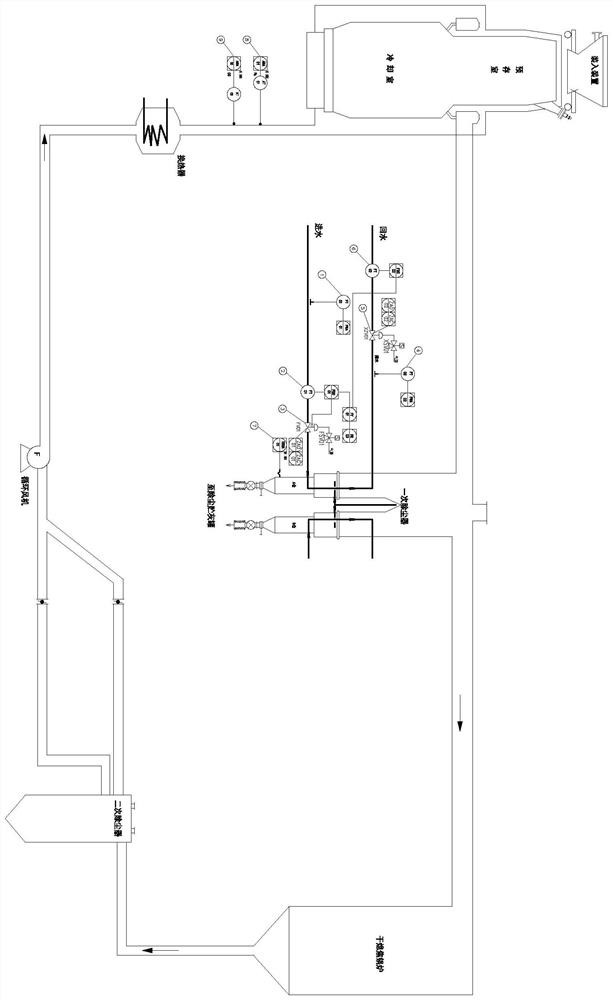

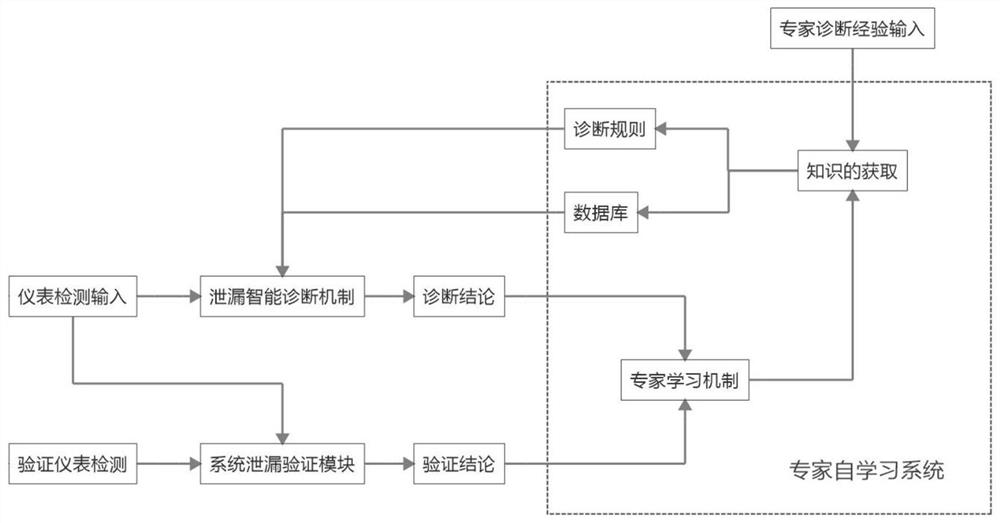

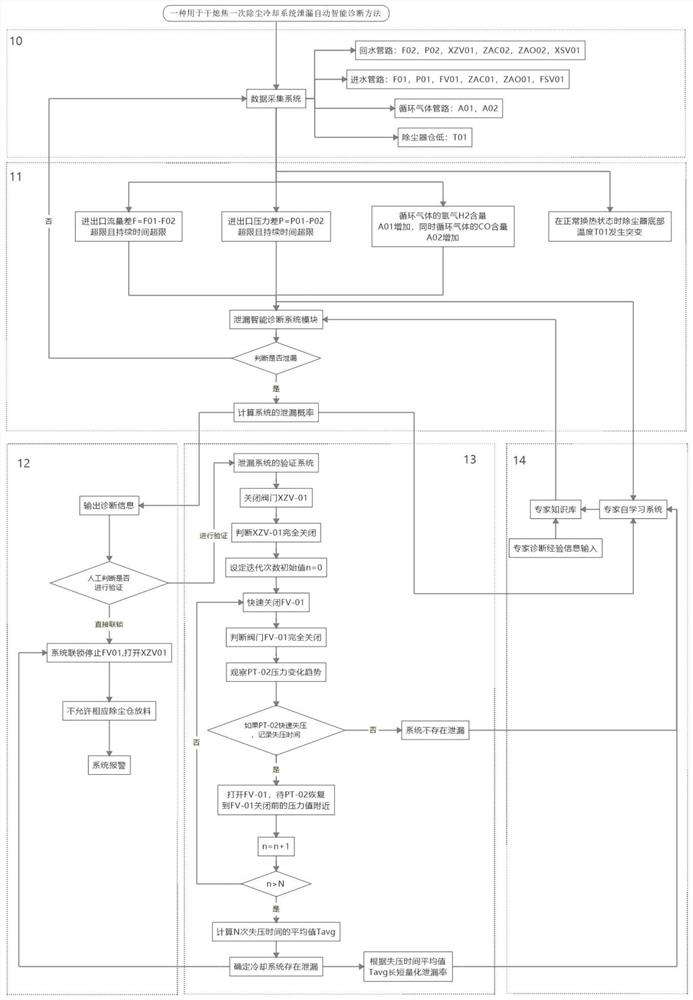

[0101] Such as Figure 1-2 As shown, a CDQ primary dedusting cooling system leakage detection system and automatic intelligent diagnosis method consists of a data acquisition module, a leakage intelligent diagnosis module, a diagnostic information output module, a system leakage verification module and an expert self-learning module. The system of the present invention is realized on the basis of the existing control system of CDQ, and the storage of the expert information database is set in the relational database for management at the upper level of the control system.

[0102] 1. Data acquisition module

[0103] Such as figure 1 As shown, the cooling system of CDQ primary dust collector is divided into A cabin and B cabin. The cooling system of cabin A and the cooling system of cabin B are set independently, and their config...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com