Ultrasonic cleaning device

A cleaning device, ultrasonic technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems affecting the quality of gluing needles and prone to residual glue, etc., to improve production efficiency , Reduce the chance of equipment crashes, and increase the effect of utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

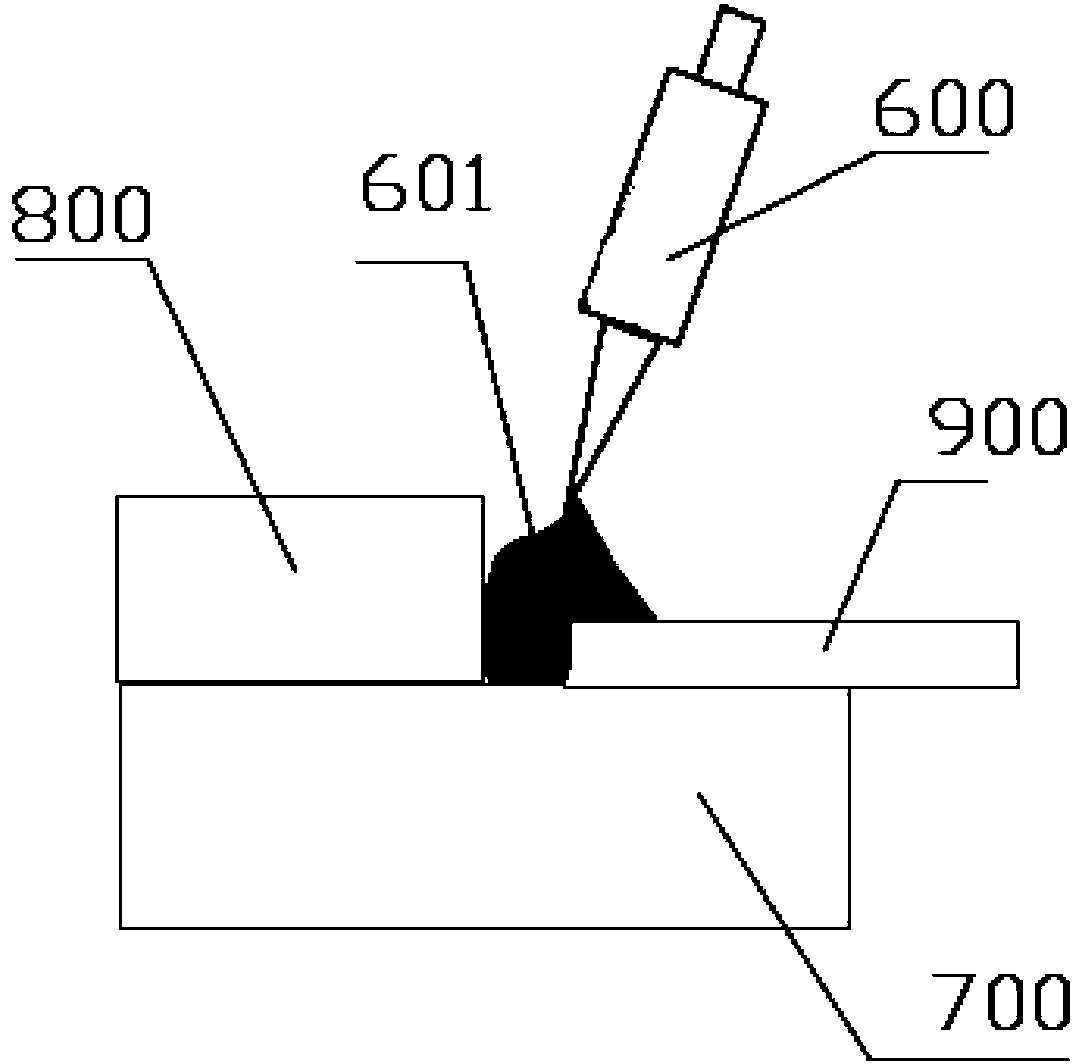

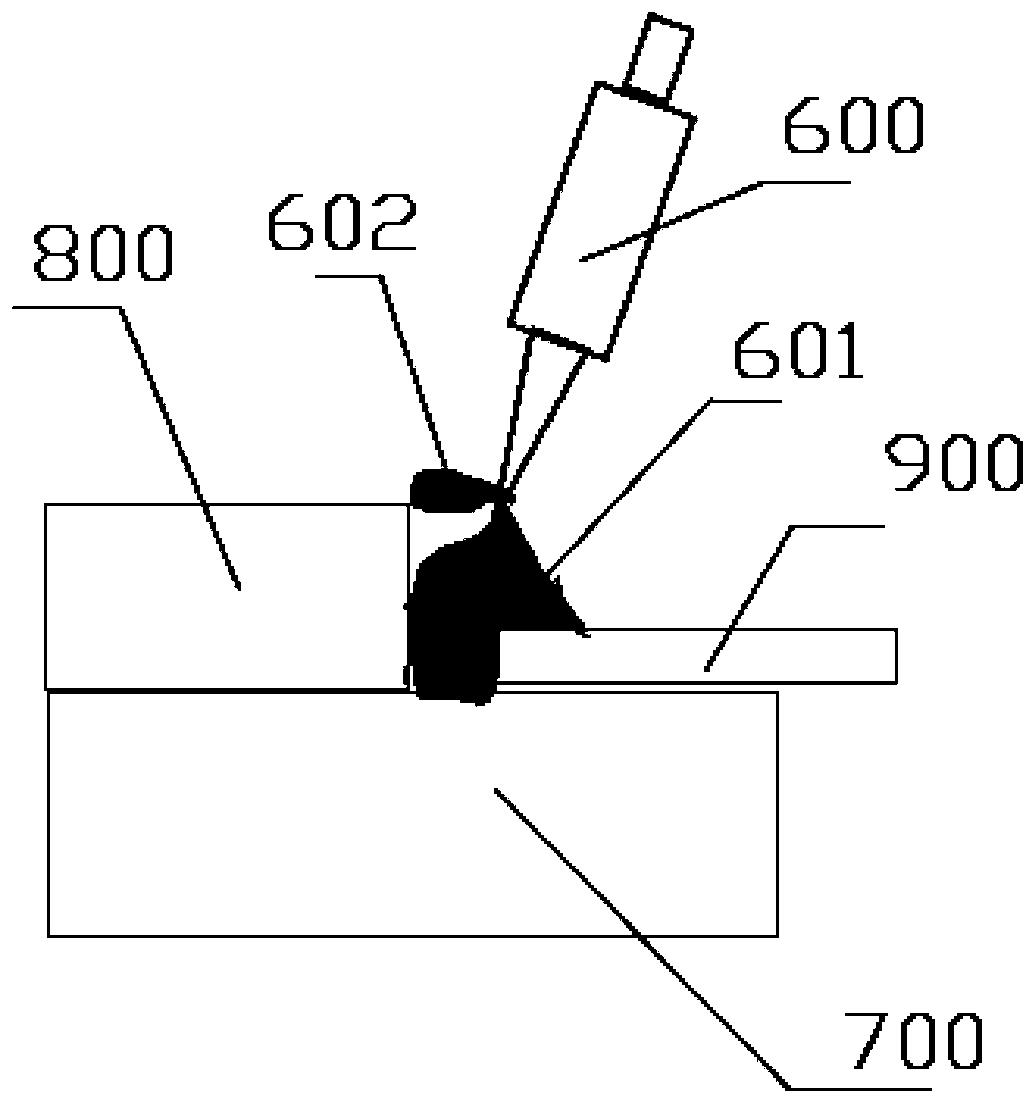

[0021] According to the existing gluing technology, since the gluing needle 600 is Figure 1.a When gluing the liquid crystal panel, the gluing needle 600 is likely to come into contact with the color filter 800 (Color Filter, CF), or the glue overflows due to the equipment crashing, resulting in the gluing needle 600 appearing as Figure 1.b The residual glue 602 in the process, and these residual glue 602 will affect the quality of the next glue application. The ultrasonic cleaning device provided by the present invention is to remove residual glue from the glue-coating needle after the glue-coating is completed, so as to ensure the quality of the next glue-coating.

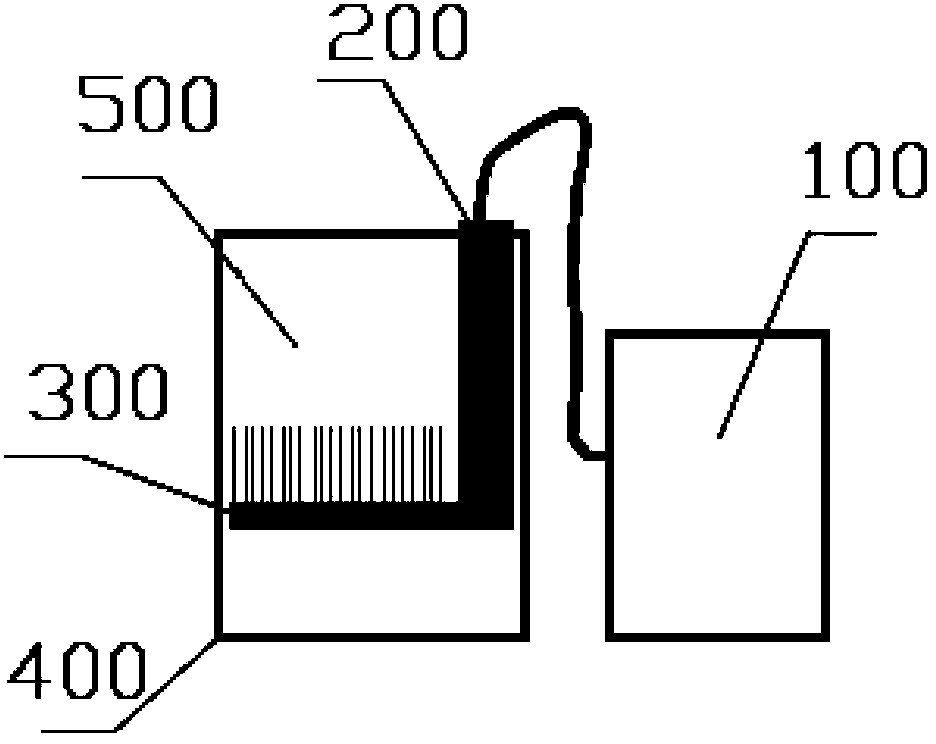

[0022] Such as figure 2 Shown is a schematic structural view of a preferred embodiment of the present invention. In this embodiment, the ultrasonic cleaning device includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com