Liquid crystal module front frame packing device

A liquid crystal module and front frame technology, which is applied in the field of liquid crystal module front frame packaging devices, can solve the problems of high packaging costs, achieve the effects of reducing packaging costs and preventing deformation of the front frame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following is attached Figures 1 to 9 Specific embodiments of the present invention will be further described.

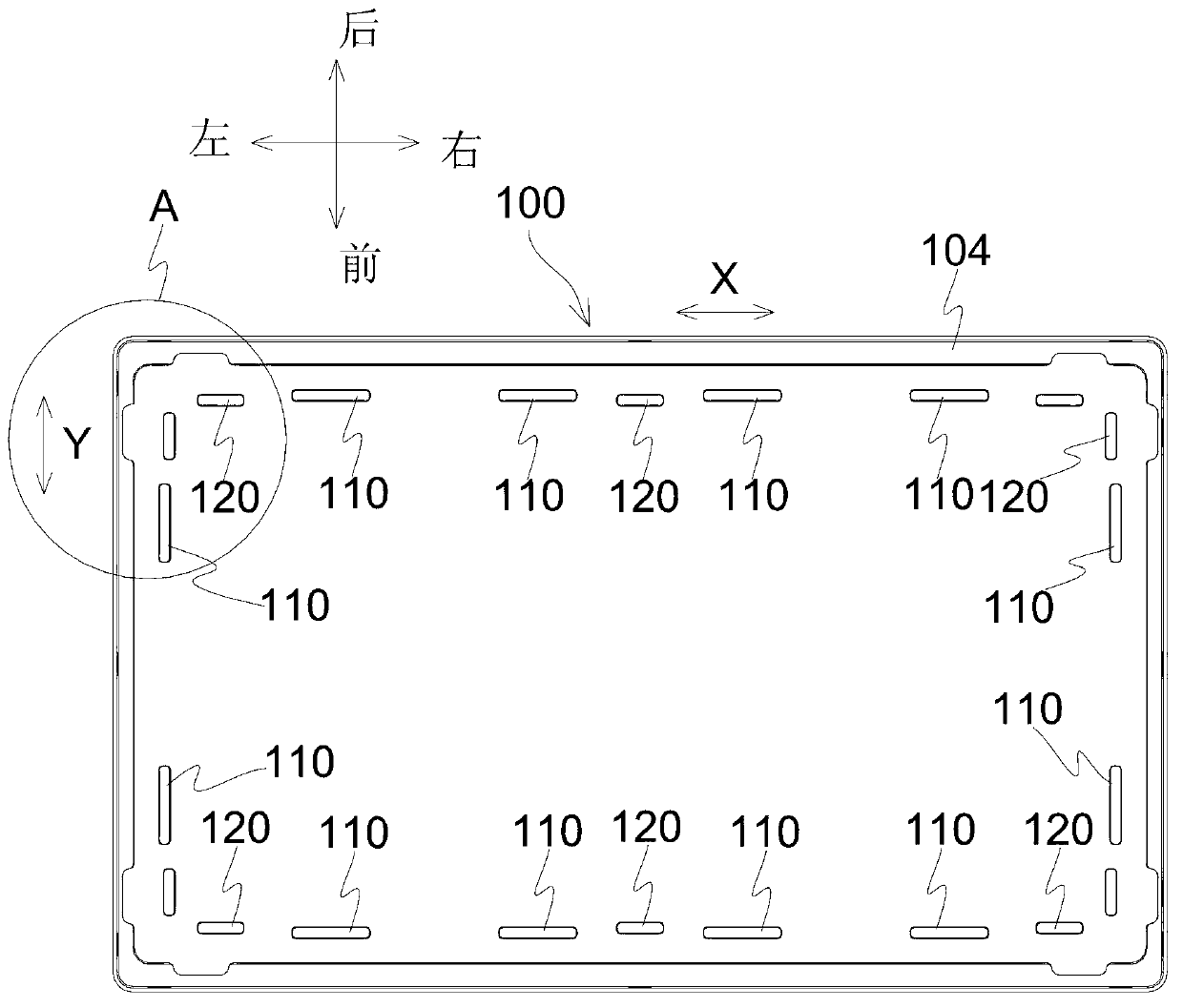

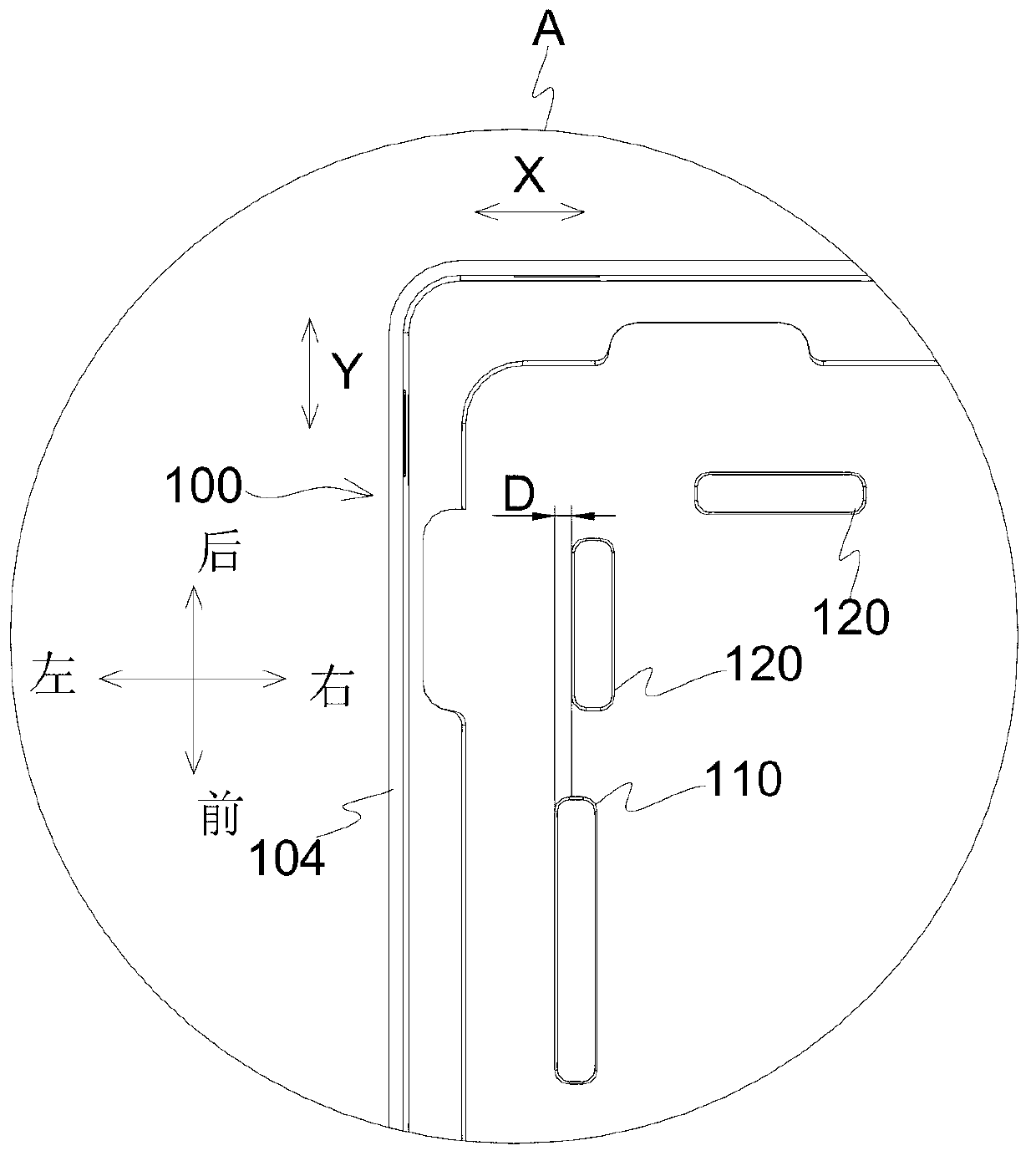

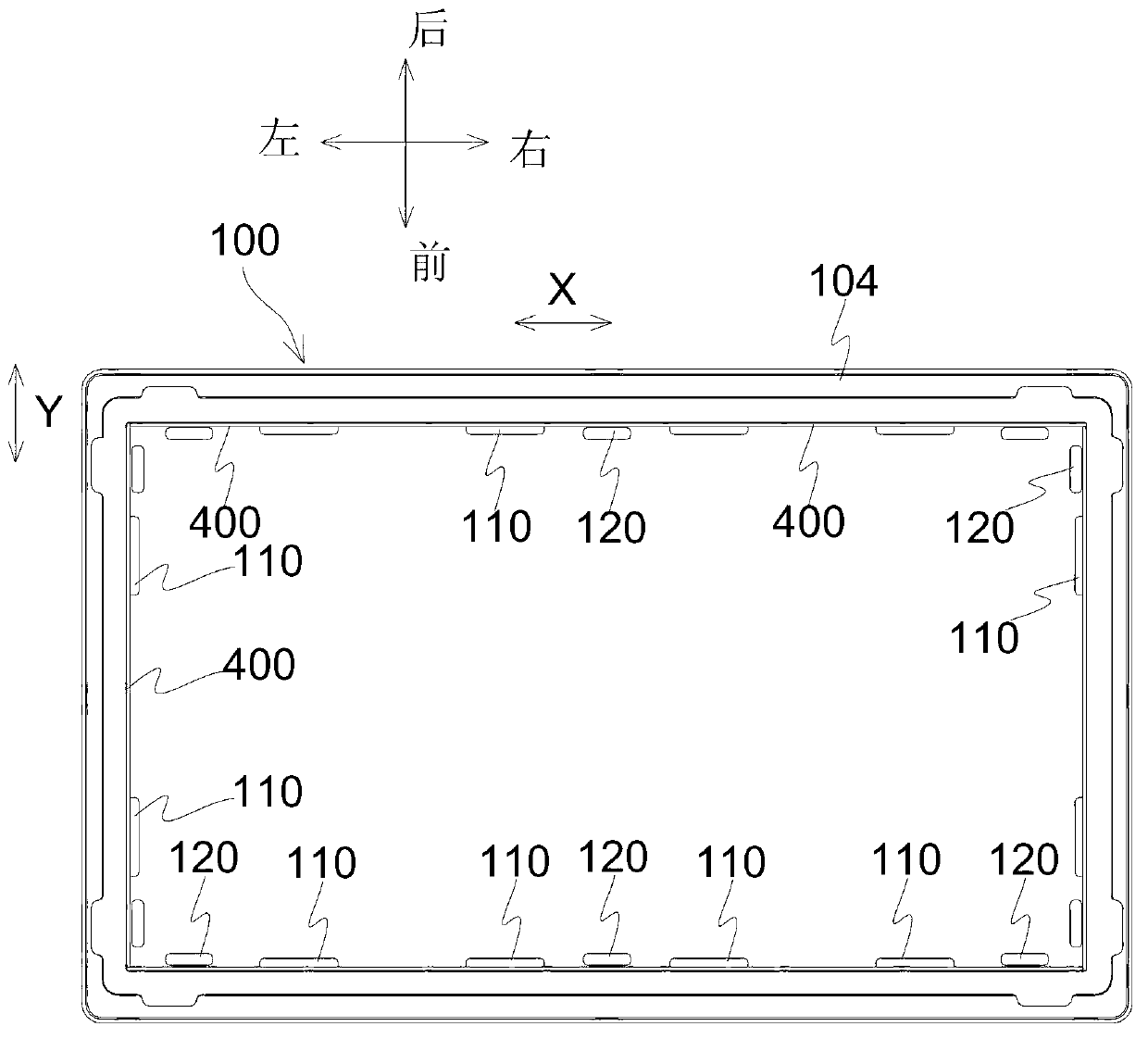

[0026] In the packaging device for the front frame of the liquid crystal module of the present invention, the packaging device for the front frame of the liquid crystal module includes a tray 100, or a plurality of trays (for example, the tray 100 and the tray 200 stacked on each other). exist Figure 8 and Figure 9 In the shown embodiment, the liquid crystal module front frame packaging device includes multiple trays (only two trays are shown, namely tray 100 and tray 200), the tray 100 and the tray 200 have the same structure, and the tray 100 and the tray 200 Snap up and down to form tray layers.

[0027] In the liquid crystal module front frame packaging device of the present invention, first protrusions 110 and second protrusions 120 are arranged around the inside of the tray 100 . Wherein, the first protrusion 110 is used to support at least tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com