Cleaning agent and cleaning method for diamond-wire cutting machine

A technology of cutting machine and diamond wire, applied in the direction of cleaning method using liquid, cleaning method and utensils, detergent composition, etc., can solve problems such as temperature rise of cutting fluid, generation of line marks, debris, affecting cutting yield, etc. , to achieve the effect of low cost, strong pertinence, good wettability and dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with examples.

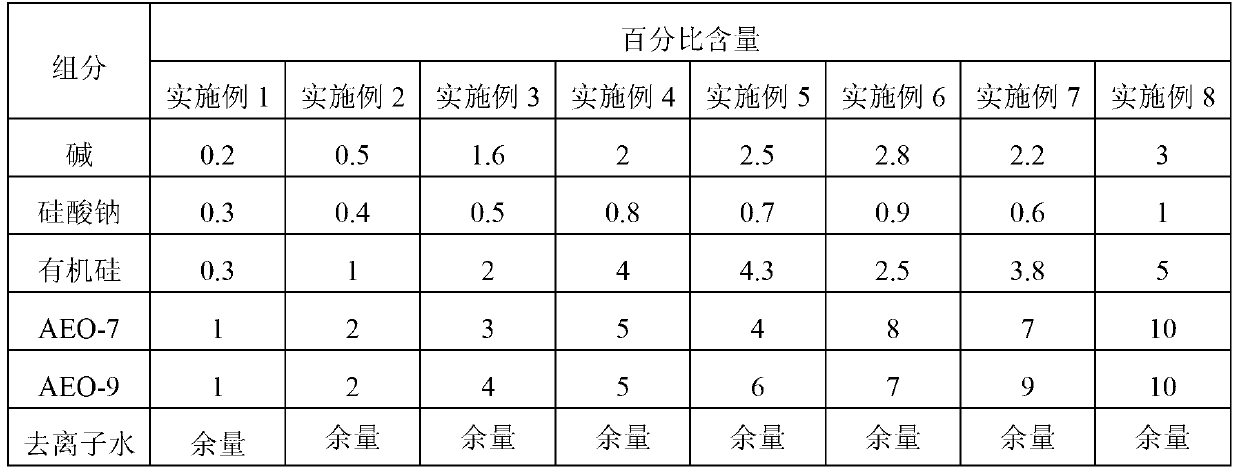

[0034] A cleaning agent for a diamond wire cutting machine, comprising the following components and the mass percentage of each component is:

[0035] Alkali: 0.2 to 3% (preferably 2 to 3%, more preferably 2%)

[0036] Sodium silicate: 0.3-1% (preferably 0.5-1%, more preferably 0.8%)

[0037] Silicone: 0.3 to 5% (preferably 3 to 5%, more preferably 4%)

[0038] AEO-7: 1 to 10% (preferably 4 to 7%, more preferably 5%)

[0039] AEO-9: 1 to 10% (preferably 4 to 7%, more preferably 5%)

[0040] Deionized water: balance.

[0041] Wherein, the base is an organic base or an inorganic base.

[0042] Using the above cleaning agent to clean the diamond wire cutting machine specifically includes the following steps:

[0043] (1) Mix part of deionized water, alkali and sodium silicate according to the ratio to obtain solution A;

[0044] (2) Mix part of deionized water, AEO-7, AEO-9 and org...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap