Modified hydrotalcite/hydroxyl iron oxide composite material and preparation methods thereof

A technology of iron oxyhydroxide and composite materials, which is applied in the fields of chemical instruments and methods, water/sewage treatment, adsorption water/sewage treatment, etc., and can solve the problems of unsatisfactory removal efficiency of heavy metal ions, small specific surface area and wettability of hydrotalcite Poor performance and other problems, achieve good removal effect, large specific surface area, and improved removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

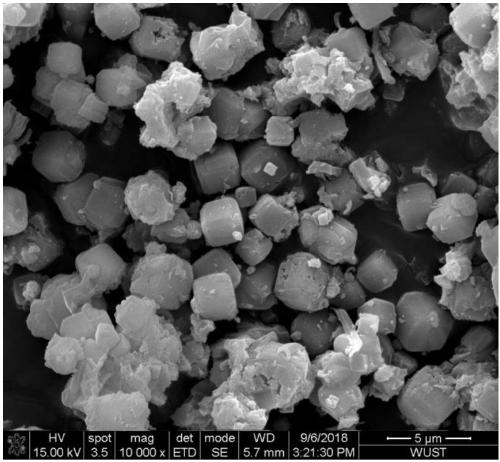

[0033] Preparation of modified hydrotalcite / iron oxyhydroxide composites

[0034] The preparation method is as follows:

[0035] (1) Prepare a dodecylpyridinium bromide solution with a concentration of 0.1mmol / L, add hydrotalcite to the dodecylpyridinium bromide solution under mechanical stirring, and the addition amount is 20g / L. Stir at 200r / min for 1.5h to prepare a modified hydrotalcite mixture;

[0036] (2) Separating the modified hydrotalcite mixture from solid to liquid, washing the solid with distilled water for 2 to 3 times, placing the washed solid in a vacuum drying oven, and drying under vacuum at 25°C for 8 hours to obtain the modified hydrotalcite Hydrotalcite;

[0037] (3) preparation concentration is the ferric chloride solution of 0.01mol / L, is that the sodium hydroxide solution of 0.5mol / L is regulated the pH value of ferric chloride solution to 2.8 with concentration, makes ferric oxyhydroxide suspension;

[0038](4) Add modified hydrotalcite to the ferri...

Embodiment 2

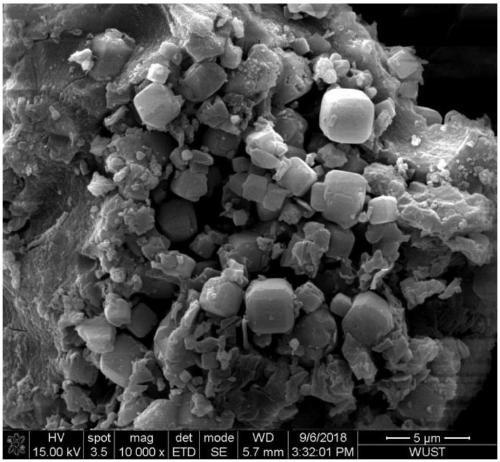

[0041] Preparation of modified hydrotalcite / iron oxyhydroxide composites

[0042] The preparation method is as follows:

[0043] (1) Prepare a cetyltrimethylammonium bromide solution with a concentration of 2mmol / L, add hydrotalcite to the cetyltrimethylammonium bromide solution under mechanical stirring, and the addition amount is 70g / L , stirred at 200r / min for 1h at room temperature to prepare a modified hydrotalcite mixture;

[0044] (2) Separating the modified hydrotalcite mixture from solid to liquid, washing the solid with distilled water for 2 to 3 times, placing the washed solid in a vacuum drying oven, and drying under vacuum at 30°C for 6 hours to obtain the modified hydrotalcite Hydrotalcite;

[0045] (3) preparation concentration is the ferric sulfate solution of 0.15mol / L, is that the sodium hydroxide solution of 1mol / L is regulated the pH value of ferric sulfate solution to 3.0 with concentration, makes ferric oxyhydroxide suspension;

[0046] (4) Add modifie...

Embodiment 3

[0049] Preparation of modified hydrotalcite / iron oxyhydroxide composites

[0050] The preparation method is as follows:

[0051] (1) preparation concentration is the octadecyltrimethylammonium chloride solution of 5mmol / L, adds hydrotalcite in the octadecyltrimethylammonium chloride solution under mechanical stirring condition, and the addition is 135g / L , stirring at 250r / min for 0.5h at room temperature to obtain a modified hydrotalcite mixture;

[0052] (2) Separating the modified hydrotalcite solution from solid to liquid, washing the solid with distilled water for 2 to 3 times, placing the washed solid in a vacuum drying oven, and drying under vacuum at 35°C for 5 hours to obtain modified water talc;

[0053] (3) preparation concentration is the ferric sulfate solution of 0.24mol / L, is that the sodium hydroxide solution of 1.5mol / L is regulated the pH value of ferric sulfate solution to 4.7 with concentration, makes ferric oxyhydroxide suspension;

[0054] (4) Add modi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap