Optimized grinding method for rail grinding wagon

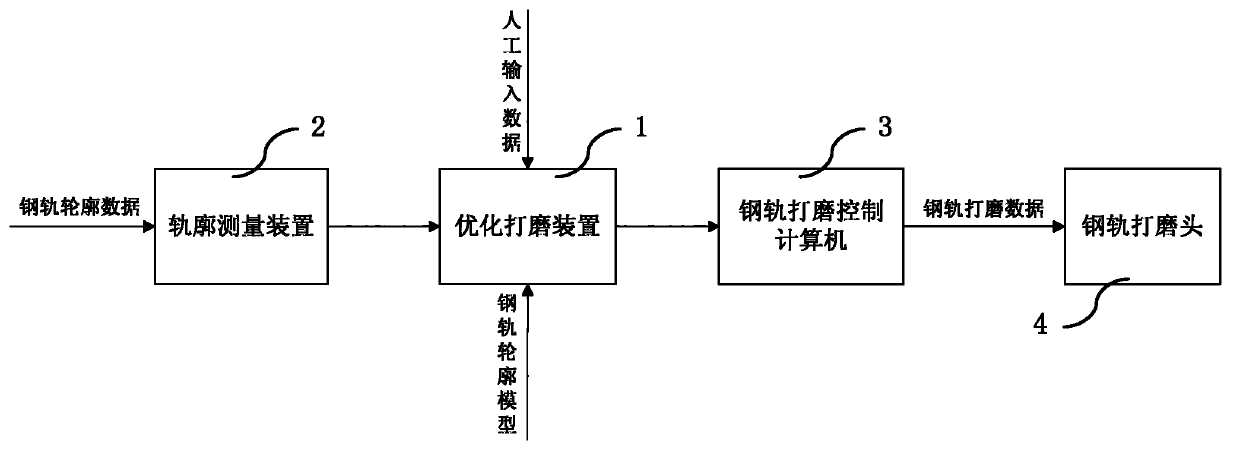

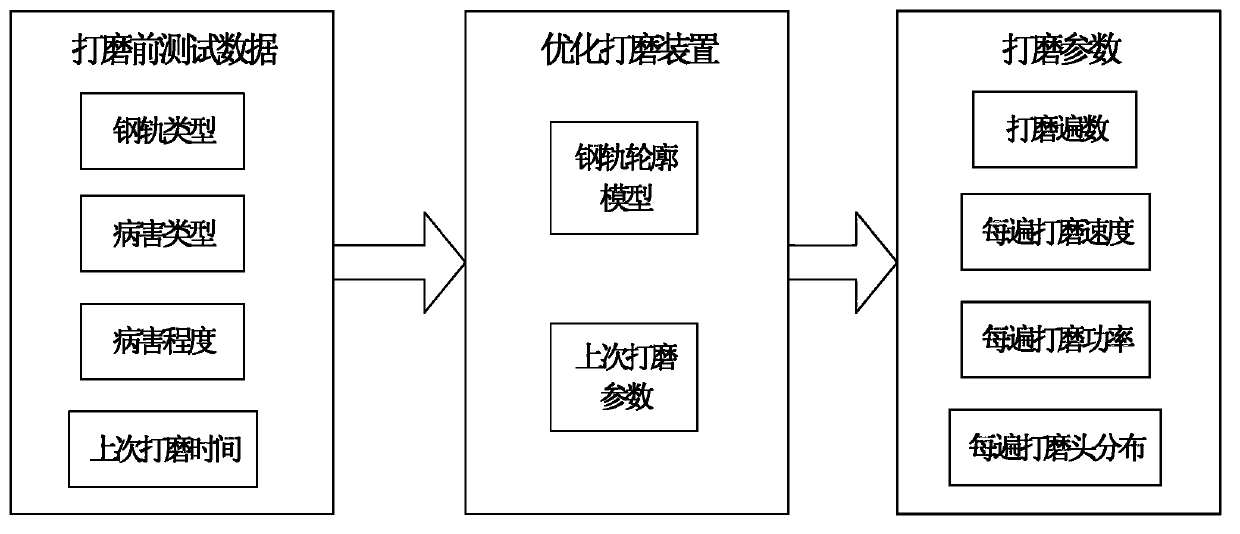

A rail grinding car and rail technology, which is applied in the direction of track, track laying, track maintenance, etc., can solve the problems of lowering operation efficiency, lack of uniform execution standards for the number of grinding times in the grinding car operation mode, and inability to perform precise operations, etc., to achieve the use efficiency Improve the effect of the improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

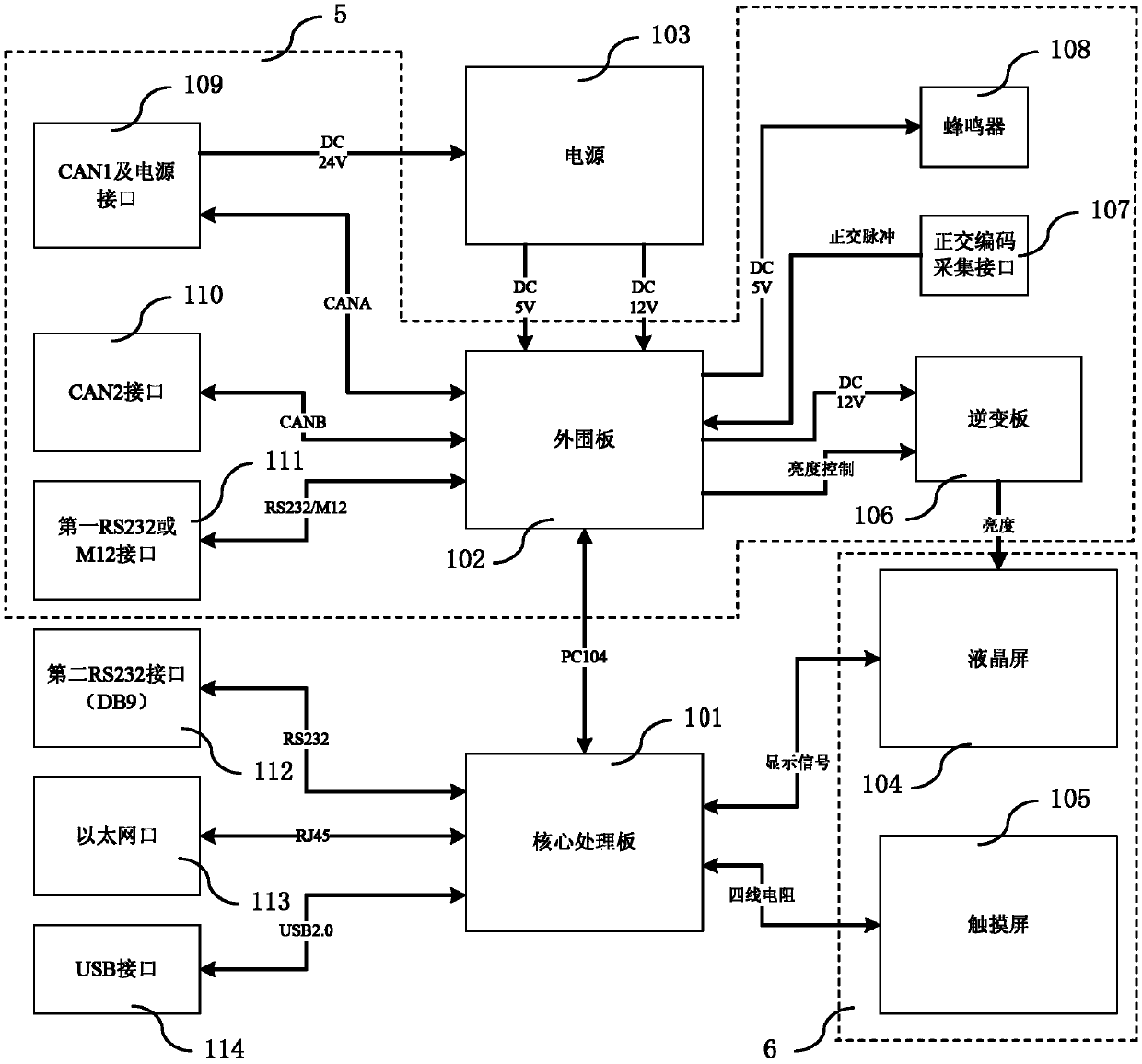

[0027] For the sake of reference and clarity, the technical terms, abbreviations or abbreviations used below are recorded as follows:

[0028] ARM: Advanced RISC Machine, the abbreviation of Advanced Reduced Instruction Set Machine, is a 32-bit reduced instruction set central processing unit architecture, which is widely used in many embedded system designs;

[0029] RS232: One of the communication interfaces on personal computers, an asynchronous transmission standard interface formulated by the Electronics Industry Association;

[0030] CAN: Controller Area Network, the abbreviation of Controller Area Network;

[0031] USB: Universal Serial Bus, the abbreviation of Universal Serial Bus;

[0032] I / O: short for input / output;

[0033] M12 interface: round four-core sensor connection cable;

[0034] DB9 interface: a 9-pin interface conforming to the RS232 bus standard;

[0035] RJ45: a common network card interface;

[0036] PC104 interface: An industrial control bus speci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com