Low-elasticity structure line and manufacturing method thereof

A technology of elastic structure and manufacturing method, applied in the direction of slender elements, building elements, etc., can solve the problems of limited performance improvement, large elastic extension of metal wire, and can not meet low extension, etc., to achieve low relaxation and good resistance to cutting tension Fluctuation, the effect of good ability to carry mortar abrasive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This embodiment is to process the high-carbon steel wire plated with brass on the surface. The high-carbon steel wire has a circular cross-section, a diameter of 0.11mm, a tensile strength of 3600MPa, and an elastic elongation of 1.2%. It is processed synchronously when drawing on a water tank wire drawing machine. complete, such as Figure 6 shown.

[0031] 1) The copper-plated steel wire is cold-drawn on the water tank wire drawing machine 1, and then drawn into a straight steel wire 100 with a diameter of 0.11 mm, a tensile strength of 3600 MPa, and an elastic elongation of 0.6% after passing through the finished product die 2.

[0032] The drawing compression rate of the finished mold 2 is 8%, therefore, the tension of the 0.11mm straight steel wire 100 behind the finished mold 2 is 11N, which is less than the yield force Rp of the high carbon steel wire 0.01 (17N).

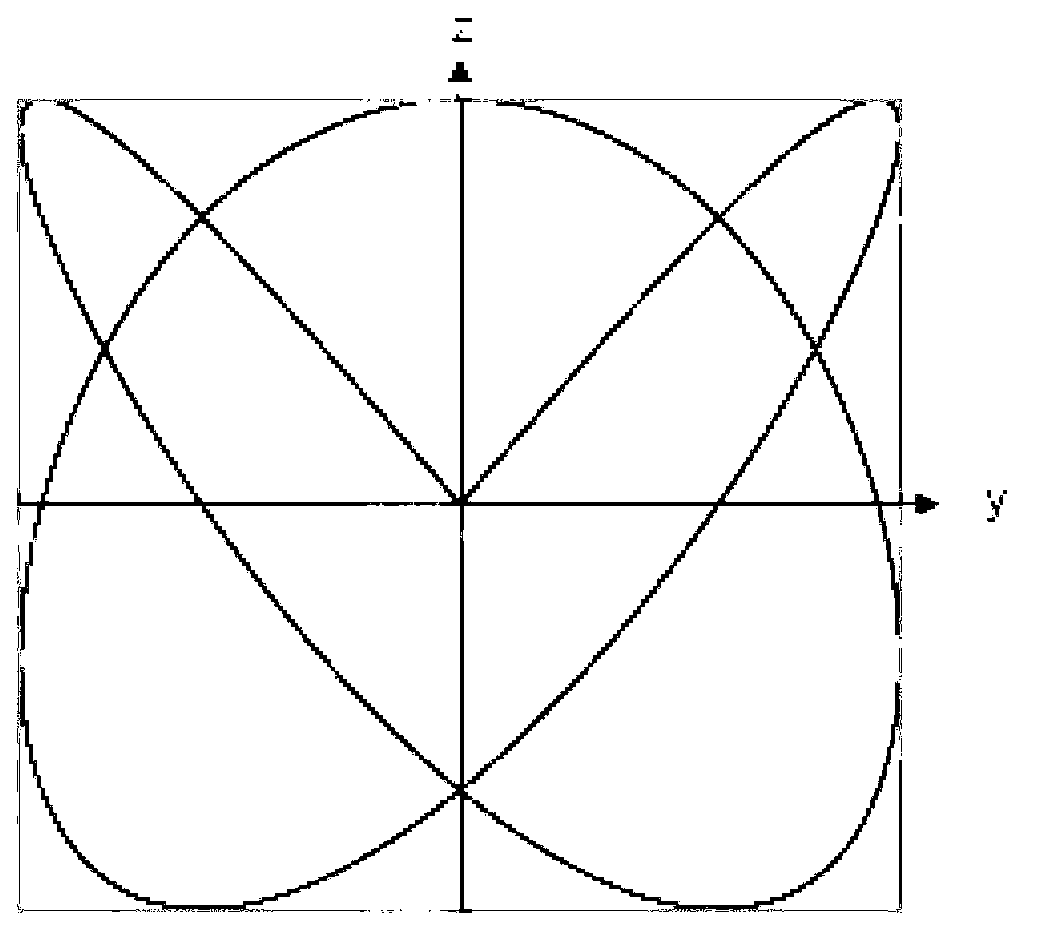

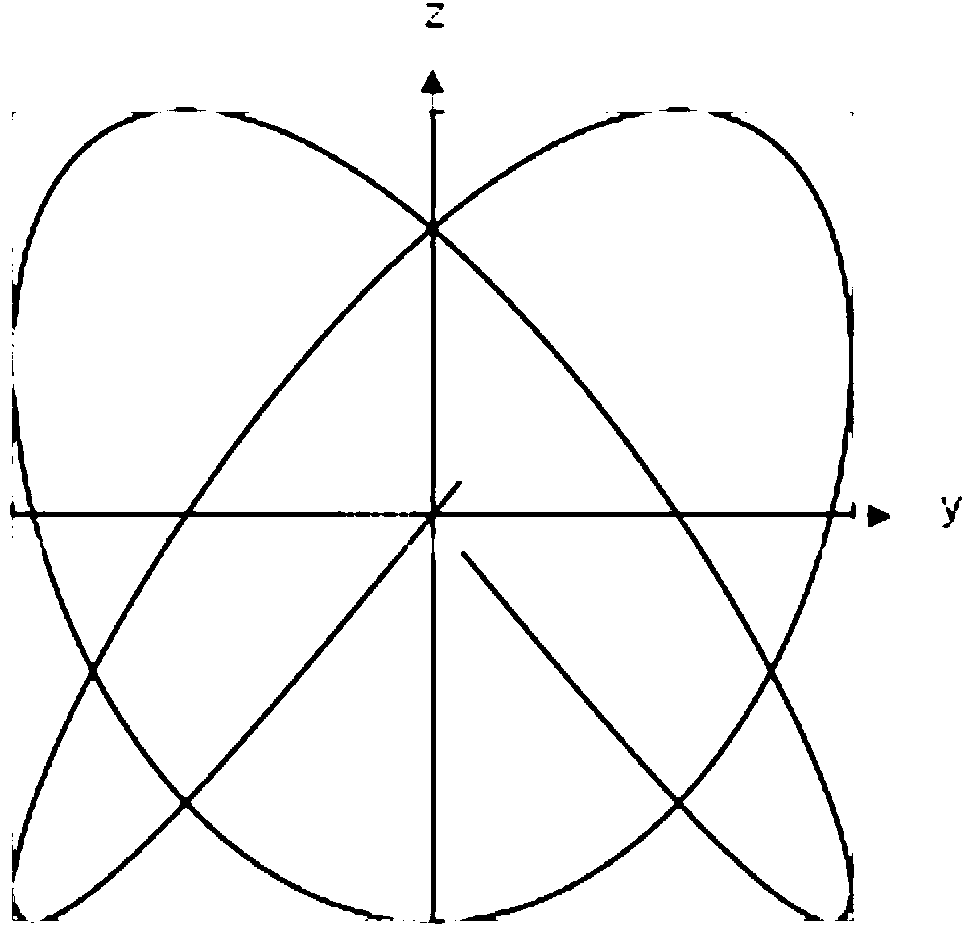

[0033] 2) The straight steel wire 100 passes through two pairs of deformed gears 3 made of alloy ...

Embodiment 2

[0039] In this embodiment, high-carbon steel wire plated with brass is processed. The high-carbon steel wire has a circular cross section, a diameter of 1.15 mm, a tensile strength of 2300 MPa, and an elastic elongation of 1.7%.

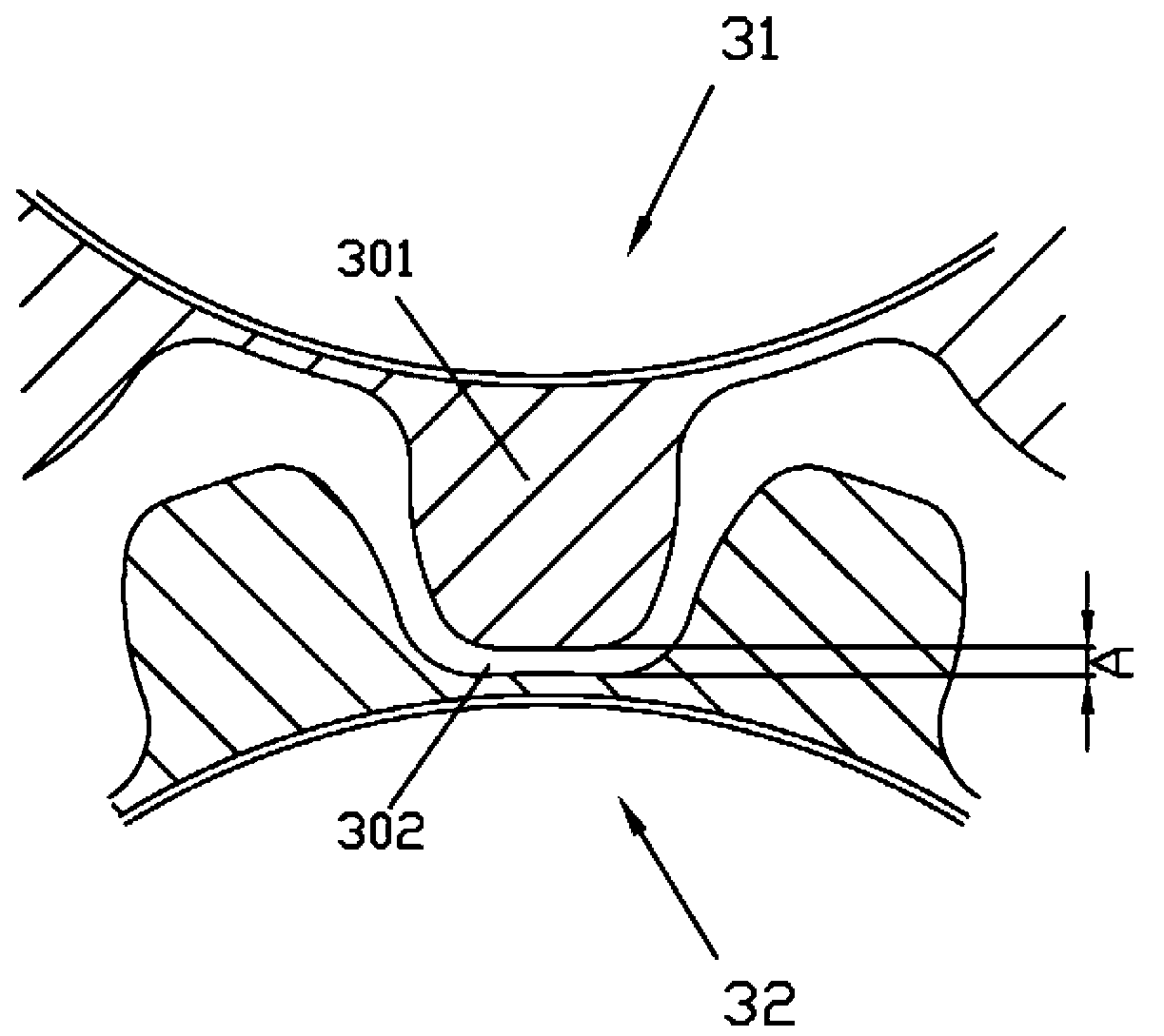

[0040] (1) The straight steel wire 100 passes through two pairs of deformed gears 3 made of alloy steel that are perpendicular to each other under a tension of 319N, wherein each gear has a diameter of 80 mm, the first pair of gears has arc-shaped teeth with 40 teeth, and the second pair of gears has The 50-tooth arc-shaped tooth can obtain a three-dimensionally curved steel wire 100' within the scope of the columnar space. By adjusting the distance A between the top of the meshed upper gear 31 arc tooth 301 and the bottom of the lower gear 32 arc tooth groove 302 to 1.33mm, the longest axis of the projection of the steel wire 100' on the y-z plane is the wire bending The weight is controlled at 2.17mm, and the elastic elongation of the metal wire afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cross section length | aaaaa | aaaaa |

| Cross section length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com