Cement-based conductive material for existing building strain monitoring and cement-based sensor

A technology of conductive materials and existing buildings, applied in conductive coatings, cement coatings, electric/magnetic solid deformation measurement, etc., can solve the problems of inability to realize strain monitoring, low bond strength of the substrate, narrow detection range, etc., and improve the conductivity Efficiency and stability, extension of bond strength, effects of a wide range of strain measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] The present invention also provides a preparation method for the cement-based conductive material coating used for strain monitoring of existing buildings, the preparation method comprising the following steps:

[0061] Step 1, taking water-based epoxy resin, conductive filler and water according to the proportion and stirring to form a slurry;

[0062] Step 2, adding the slurry into the cement according to the proportion, stirring until uniformly forming a slurry;

[0063] Step 3: scrape or spray the slurry on the surface of the existing building structure, and harden after curing to form a cement-based conductive material coating.

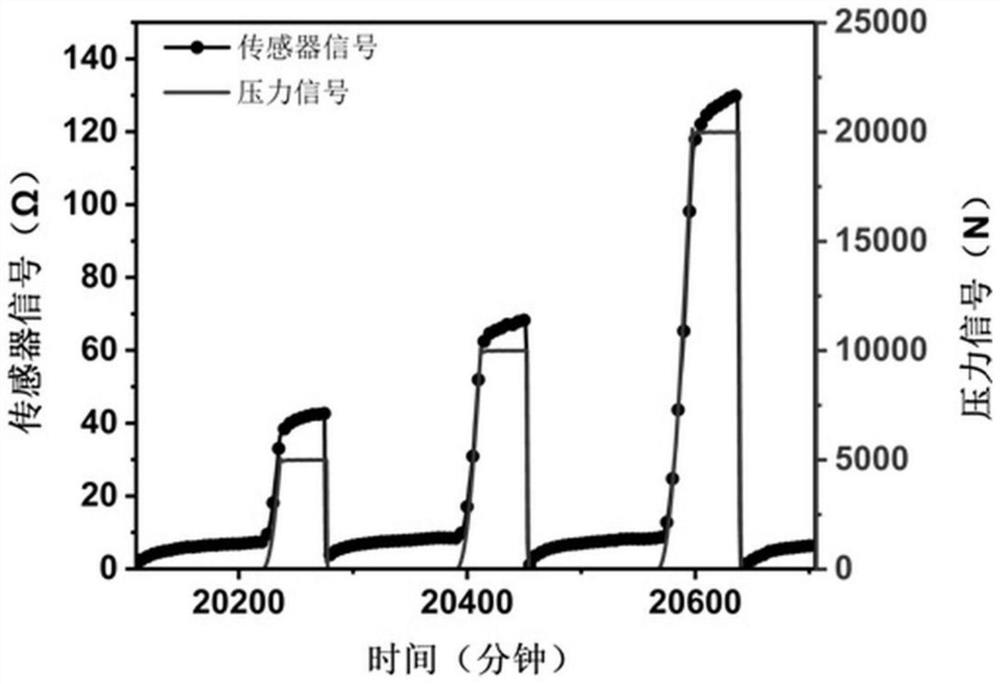

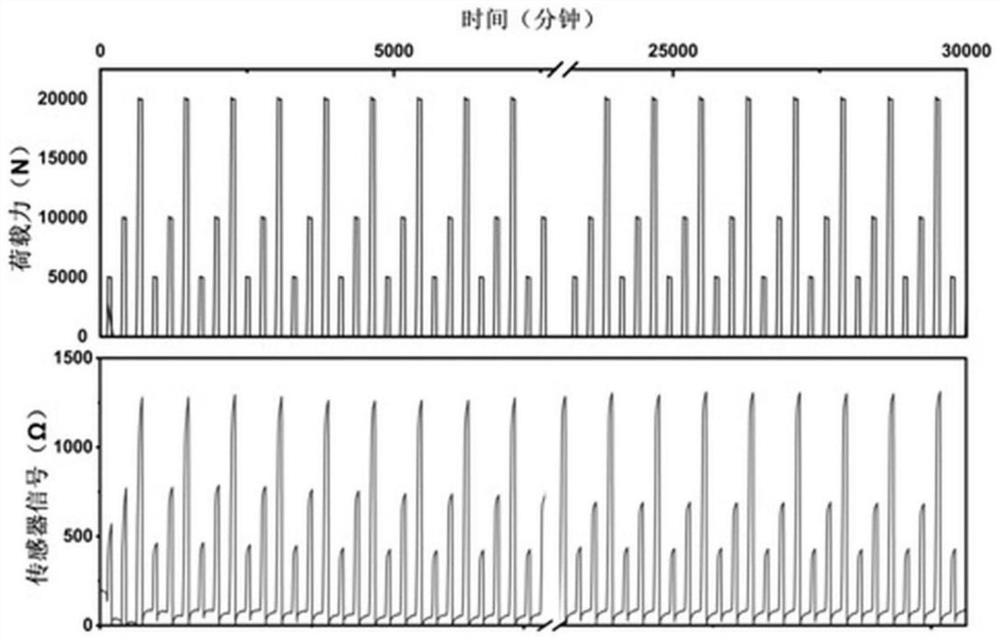

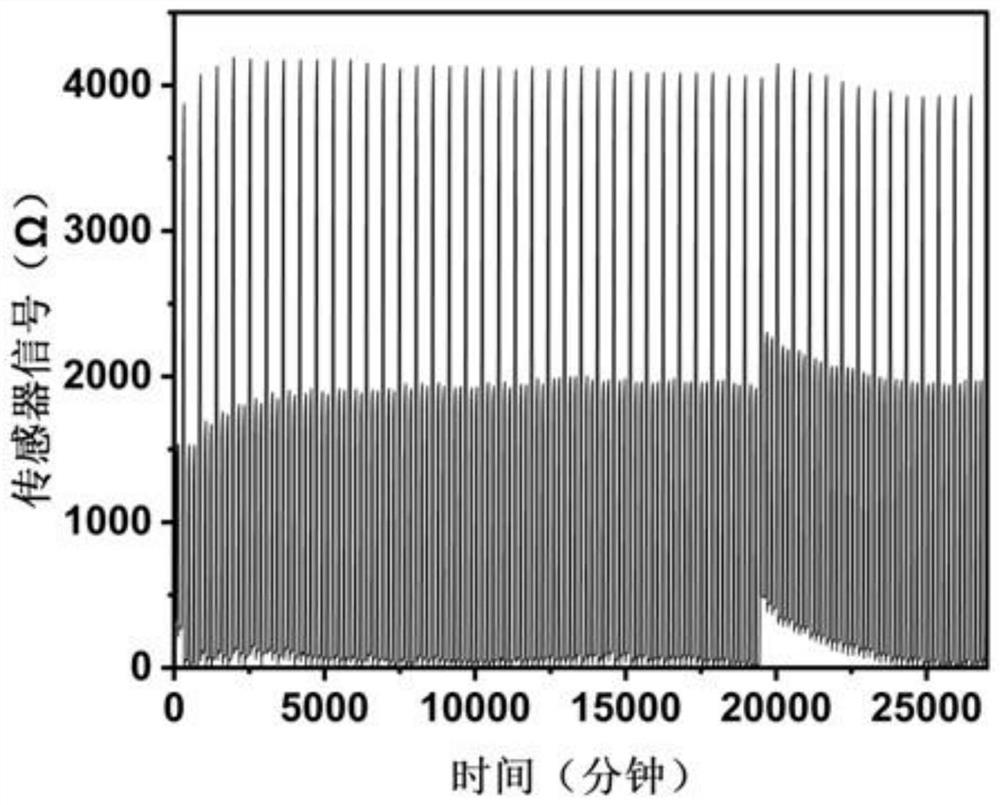

[0064] The present invention also provides a cement-based sensor, which includes the above cement-based conductive material or the above cement-based conductive material coating, and the cement-based sensor also includes a conductive material installed on the surface of the existing building structure in the area where the coating is appli...

Embodiment 1

[0069] This embodiment provides a cement-based conductive material for strain monitoring of existing buildings. The conductive material specifically includes the following components in mass percentage:

[0070] Anionic water-based epoxy resin 20%, ordinary portland cement 50%, conductive filler 10% (including carbon nanotube 2%, graphene oxide 8%), water 20%.

[0071] The preparation method of cement-based conductive material coating comprises the steps:

[0072] Weigh the required water, water-based epoxy resin, and conductive filler according to the formula ratio and stir until uniformly mixed into a slurry; then slowly add the slurry into the uniformly mixed cement according to the formula ratio, and stir until a uniform slurry; The slurry is scraped or sprayed on the lower surface of the concrete beam and cured for 3 days at a curing temperature of 25°C. After hardening, a cement-based conductive material coating is obtained. The thickness of the cement-based conductive ...

Embodiment 2

[0080] In this embodiment, the specific components of the cement-based conductive material are changed, and the other method steps are the same as those in Embodiment 1, and will not be repeated here.

[0081] The cement-based conductive material specifically includes the following components in mass percentage:

[0082] Cationic water-based epoxy resin 10%, slag portland cement 55%, conductive filler 5% (including graphite 3%, carbon black 2%) and water 30%.

[0083] According to the performance test standard as in Example 1, the cement-based conductive material prepared in this embodiment is tested for performance, and the performance results are as follows:

[0084] The bonding strength between the cement-based coating and the concrete beam is 2.61MPa, the surface has no cracks, no warping, no deformation, and the freeze-thaw durability index of the beam concrete increases from DF=95% to DF=98%. The stress-strain curve of the beam body during the bending fracture process a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com