Non-contact automatic displacement monitoring device

An automatic monitoring, non-contact technology, applied in measurement devices, optical devices, surveying and navigation, etc., can solve the problems of limited monitoring frequency of the measured object, high requirements for operators of precision instruments, and high cost. The effect of low cost, reduced labor intensity, and accurate measurement data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

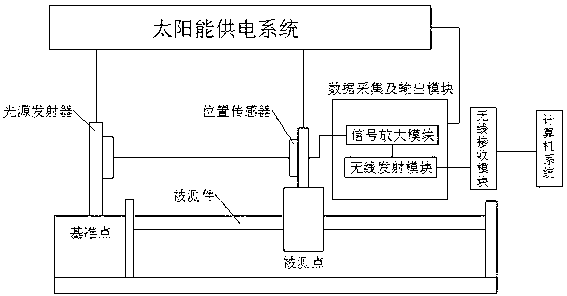

[0035] like figure 1 As shown, in order to measure the one-dimensional settlement deformation of rock and soil, the non-contact displacement automatic monitoring device includes:

[0036] Visible infrared light emitters for emitting light;

[0037] A one-dimensional position sensor for receiving the light emitted by the light source emitting device and measuring the position movement;

[0038] A data acquisition and output module for receiving, processing and wirelessly transmitting the information output by the position sensor;

[0039] A wireless receiving module for wirelessly receiving the information output by the data acquisition and output module;

[0040] A solar power supply system for providing power to the light source emitting device, position sensor, data acquisition and output module;

[0041] And a computer system that receives and processes the information output by the wireless receiving module, and displays the actual position movement result.

[0042] Th...

Embodiment 2

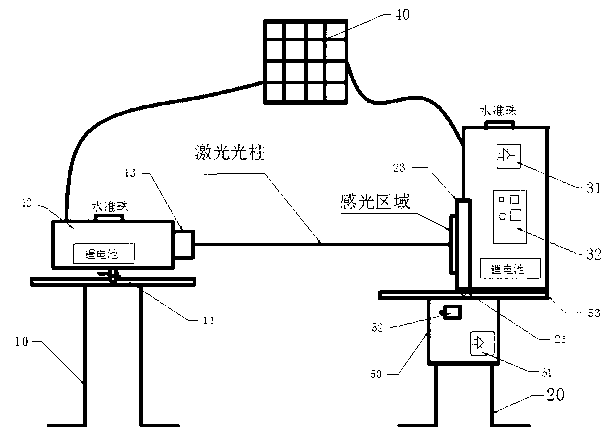

[0053] In order to monitor the deformation of the horizontal displacement and vertical displacement of the measured object and better realize the monitoring of field projects, such as image 3 As shown, the difference between the non-contact automatic displacement monitoring device in Embodiment 2 and Embodiment 1 is:

[0054] 1) The light source transmitter 12 is a laser transmitter, which has a built-in high-performance 5V rechargeable lithium battery; the laser transmitter is installed on the light source transmitter bracket 10 through the transmitter universal adjustment device 11; Adjustment ring 13.

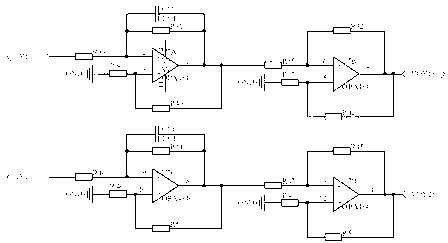

[0055]2) The position sensor 23 is a two-dimensional position sensor, which is equipped with a high-performance 5V rechargeable lithium battery inside; the signal amplification module 31 and the wireless transmission module 32 of the data acquisition and output module are built in the two-dimensional position sensor, and the signal amplification module 31 as Figure 4 sho...

Embodiment 3

[0061] In order to monitor the three-dimensional deformation of the measured body, i.e. the horizontal displacement of the measured body, the vertical displacement and the distance change between the fixed point and the measured point, the difference between embodiment 3 of the present invention and embodiment 1 is:

[0062] 1) The light source transmitter is a laser rangefinder, which has a built-in high-performance 5V rechargeable lithium battery; the laser rangefinder has a spot focusing device, which is used to measure the object under test and the laser beam while emitting laser light as a light source. The accuracy of the displacement data between the range finders can reach 1mm. The laser rangefinder transmits the obtained displacement data to the data collection and output module, and after filtering and amplifying processing by the data collection and output module, it is output together with the information obtained by the position sensor.

[0063] 2) The position se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com