Claw-type planetary gear train planting mechanism

A technology of planetary gear system and horns, applied in transplanting machinery, planting methods, mechanical equipment, etc., can solve the problems of short time for seedlings to be put into baskets, inability to carry multiple hanging baskets, difficulty in high-speed transplanting, etc., and achieve structural design Novel and reasonable, increase the time to enter the basket, and improve the quality of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

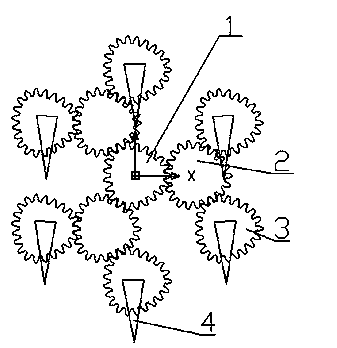

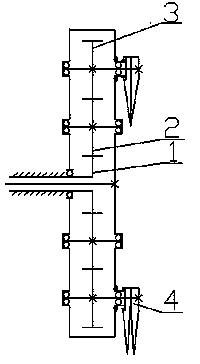

[0013] Embodiment 1: A claw-type planetary gear train planting mechanism, 2-5 non-circular intermediate gears 2 are evenly distributed outside the periphery of the non-circular sun gear 1, and the non-circular sun gear 1 is connected with 2-5 non-circular sun gears respectively. The non-circular intermediate gear 2 meshes, and two non-circular outer gears 3 are arranged on the outer part of each non-circular intermediate gear 2 respectively meshing with it, and the non-circular sun gear 1 is connected with a non-circular intermediate gear 2 and 2 non-circular sun gears. The outer gear 3 forms a claw-type planetary gear train; on each non-circular outer gear 3, the hanging basket 4 is swingably suspended.

[0014] When transplanting, the power output device drives the non-circular sun gear 1 to rotate, and the non-circular sun gear 1 drives the non-circular intermediate gear 2 to rotate through meshing. After the non-circular intermediate gear 2 rotates, it drives 2 non-circular...

Embodiment 2

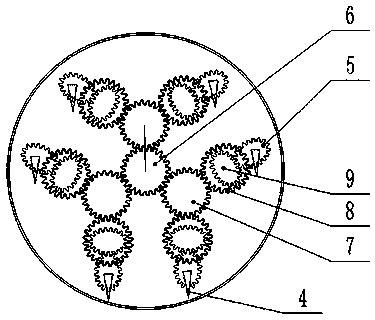

[0015] Embodiment 2: A claw-type planetary gear train planting mechanism, 2-5 cylindrical intermediate gears 7 are evenly distributed outside the periphery of the cylindrical sun gear 6, and the cylindrical sun gear 6 is connected with 2-5 cylindrical sun gears respectively. 7 meshing cylindrical intermediate gears, two cylindrical external gears 8 meshing with each cylindrical intermediate gear 7 are arranged on the outer side of each cylindrical external gear 8, and a non-circular driving gear 9 is coaxially fixed on each cylindrical external gear 8. A non-circular driven gear 5 meshing with a non-circular driven gear 9 is arranged on the outer side, consisting of a cylindrical sun gear 6, a cylindrical intermediate gear 7, 2 cylindrical external gears 8, and 2 non-circular driving gears 9 And 2 non-circular driven gears 5 form a claw-type planetary gear train; on each non-circular driven gear 5, hang and assemble the hanging basket 4 swingably.

[0016] When transplanting, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com