Solar cell panel cleaning system in photovoltaic power station

A technology for solar panels and photovoltaic power plants, which is applied to solar heating systems, solar thermal power generation, photovoltaic power generation, etc., can solve the problems that the panels are difficult to achieve a better cleanliness, are easy to block the solar panels, and affect the lighting of the panels, etc. To achieve the effect of reasonable position relationship, clean and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

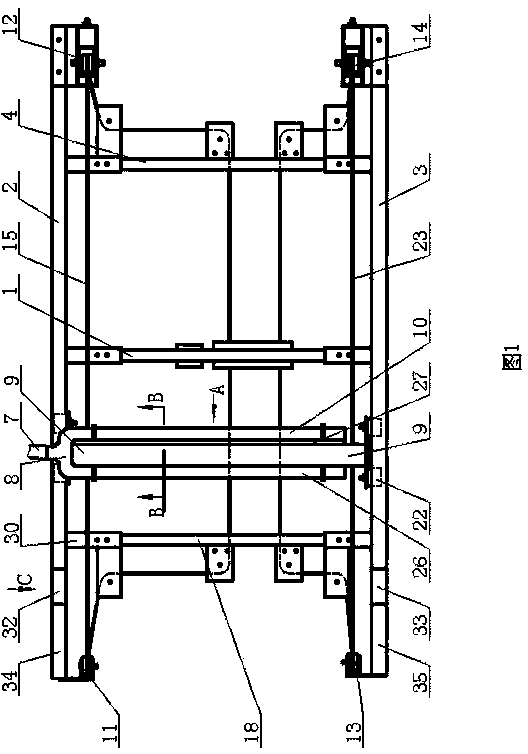

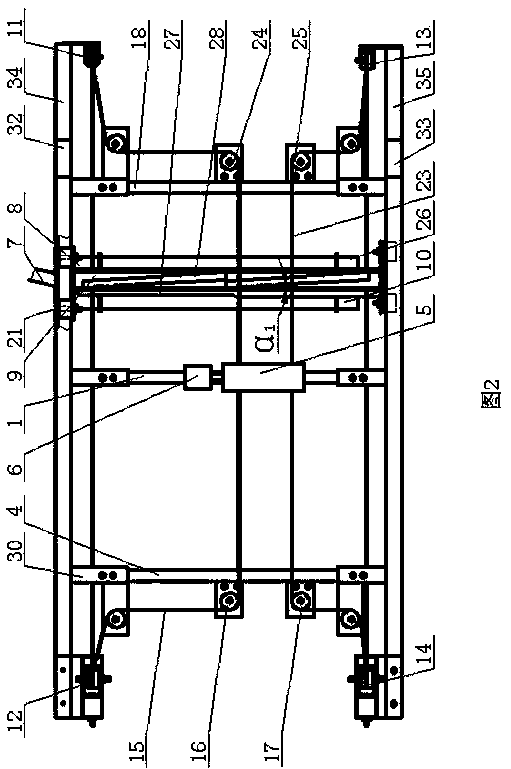

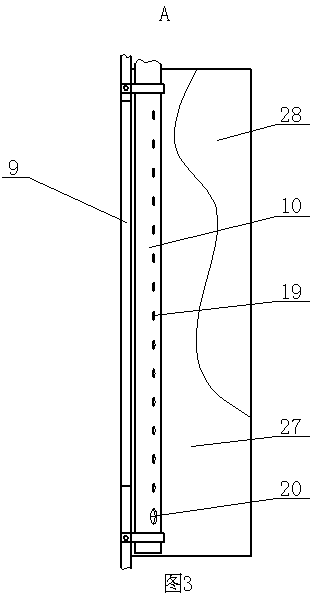

[0010] The present invention will be further described with reference to the accompanying drawings.

[0011] Among the figure 2 is the upper track, 3 is the lower track, the first roller 21 is installed in the upper track 2, the second roller 22 is installed in the lower track 3, the cleaning device support 9 is installed on the first roller 21 and the second roller 22, and the cleaning device support 9 The first water spray pipe 10 and the second water spray pipe 26 are respectively installed on both sides, the first water spray pipe 10 and the second water spray pipe 26 are connected with the water inlet pipe 7 through the reversing valve 8, the first water spray pipe 10 and the second water spray pipe Two water spray pipes 26 offer several water spray holes 19 along the length direction, a brush 27 and a cleaning wiper strip 28 are installed on the cleaning device bracket 9, and the hairbrush 27 and the cleaning wiper strip 28 are located in the first water spray pipe. 10 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com