Anti-UV energy-saving water repellent film used for navigation airplane cockpit glass and preparing method of anti-UV energy-saving water repellent film

A technology of aircraft cockpit and hydrophobic film, which is applied in air transportation, sustainable transportation, ion implantation plating, etc. It can solve the problems of improving hydrophobic performance and the lack of UV protection on the outer surface of glass, so as to achieve excellent hydrophobic performance and production The process is independently controllable, and the effect of reducing condensation and traces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

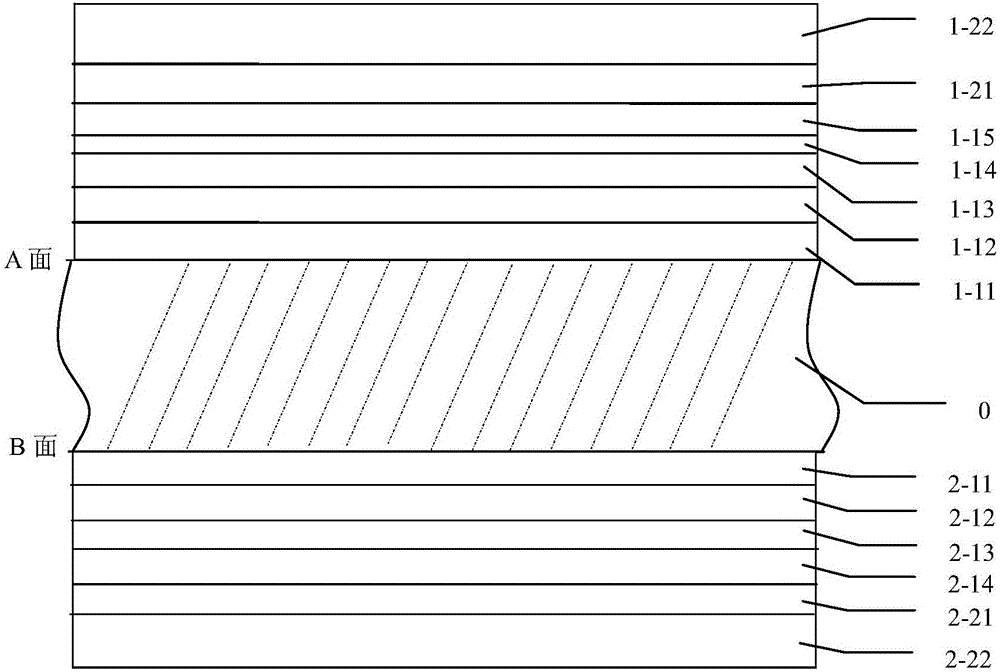

[0033] A kind of anti-ultraviolet and energy-saving hydrophobic film for cockpit glass of general aviation aircraft of the present invention, described anti-ultraviolet and energy-saving hydrophobic film for cockpit glass of general aviation aircraft comprises plexiglass substrate O, and A is arranged on the plexiglass substrate (0) Surface and B surface, the A surface and the B surface are respectively provided with different transparent films, the A surface is an energy-saving transparent conductive film system, and the B surface is an ultraviolet-proof hydrophobic transparent film system;

[0034] The energy-saving transparent conductive film is composed of organic glass substrate, energy-saving functional layer and protective layer from inside to outside; the anti-ultraviolet hydrophobic transparent film is composed of organic glass substrate, ultraviolet-proof functional layer and hydrophobic functional layer in sequence from inside to outside.

[0035] The inner side of t...

Embodiment 2

[0046] The difference between embodiment 2 and embodiment 1 is: a kind of anti-ultraviolet and energy-saving hydrophobic film used for the cockpit glass of general aviation aircraft of the present invention, the film thickness of the silicon oxide layer 1-11 is 16nm, the first niobium oxide layer 1 -12 has a film thickness of 28nm, the first zirconia layer 1-13 has a film thickness of 19nm, the metal layer 1-14 is a gold metal silver layer, and the metal layer 1-14 has a film thickness of 10nm, The film thickness of the second zirconia layer 1-15 is 18nm.

[0047] The protective layer on the A surface is sequentially composed of a second niobium oxide layer 1-21 and an indium tin oxide layer 1-22 from the inside to the outside; the film thickness of the second niobium oxide layer 1-21 is 28nm, and the indium oxide layer The film thickness of the tin layers 1-22 is 80nm.

[0048] The anti-ultraviolet functional layer on the B side is sequentially composed of the first silicon ...

Embodiment 3

[0056] The difference between embodiment 3 and embodiment 1 is: a kind of anti-ultraviolet and energy-saving hydrophobic film for the cockpit glass of general aviation aircraft of the present invention, the film thickness of described silicon oxide layer 1-11 is 20nm, the first niobium oxide layer 1 -12 has a film thickness of 35nm, the first zirconia layer 1-13 has a film thickness of 22nm, the metal layer 1-14 is a gold metal silver layer, and the metal layer 1-14 has a film thickness of 12nm, The film thickness of the second zirconia layer 1-15 is 22nm.

[0057] The protective layer on the A surface is sequentially composed of a second niobium oxide layer 1-21 and an indium tin oxide layer 1-22 from the inside to the outside; the film thickness of the second niobium oxide layer 1-21 is 30nm, and the indium oxide layer The film thickness of tin layers 1-22 is 110 nm.

[0058] The anti-ultraviolet functional layer on the B side is sequentially composed of the first silicon o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com