Sand mould compressing frame for brake hub moulding line

A molding line and brake hub technology, applied in the field of molding sand pressing frame, can solve problems such as box expansion, insufficient compaction of casting mold, sand washing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

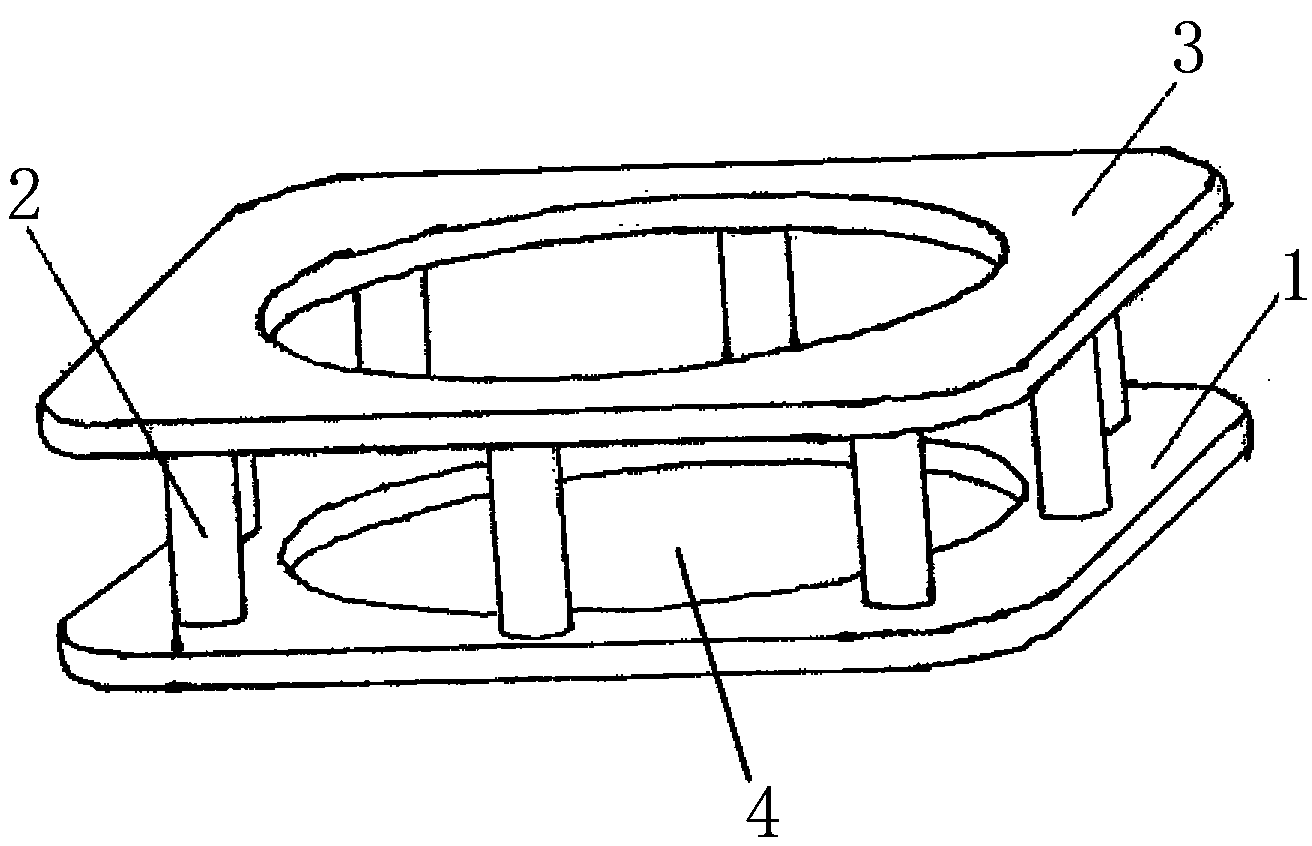

[0009] Such as figure 1 As shown, the present invention supports and connects an upper fixing plate 3 above the sand pressing plate 1 through a plurality of connecting columns 2, and a circular mold avoidance hole 4 is respectively provided at the middle of the upper fixing plate 3 and the sand pressing plate 1, so that The above-mentioned fixed plate 3 corresponds to the circular mold avoidance hole 4 on the sand pressing plate 1 . Through the above settings, the upper fixing plate 3 of the present invention is connected with the upper pressing plate of the casting sand molding machine, the sand pressing plate 1 can compact the various parts of the sand mold of the brake hub, and the sand mold can enter the circular mold avoidance hole 4, The collision between the sand mold and the sand press plate 1 is avoided, and the sand press plate 1 keeps pressing down until the sand mold is compacted to ensure the compaction strength.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap