Construction process of roadbed structure with sand-based water-permeable bricks

A construction process and technology of permeable bricks, applied in the direction of condensable pavement, roads, roads, etc. paved on site, can solve the problem of neglecting environmental protection, improve the comfort and safety of traffic, prevent road surface reflection, and improve survival. The effect of the condition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

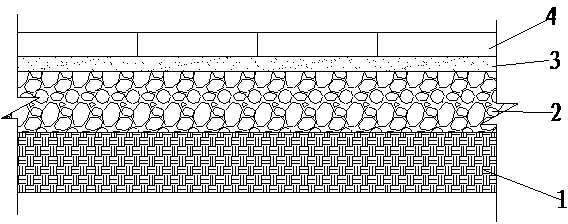

[0038] A construction process for a subgrade structure with sand-based permeable bricks, the construction process includes the following process steps:

[0039] A. Construction preparation, B. Measurement and setting out, C. Base construction, D. Bearing layer construction, E. Leveling layer construction, F. Sand-based permeable brick paving, G. Filling joints, H. Maintenance, I. Site cleaning;

[0040] In A, construction preparation steps:

[0041] Determine the paving structure, which is divided into three layers: sand-based permeable bricks, leveling layer, and bearing layer; according to the different functions of the road surface, it is divided into the following three categories: sidewalk paving, parking lot paving, and roadway paving;

[0042] In the step of B, measurement and setting out:

[0043] Carry out re-test lines for given control points, and carry out on-the-spot laying-out according to the design drawings, and calibrate the elevation, which is a pile of 10m....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com