Linear coal ash aerated concrete concavo-convex building block and masonry method thereof

A technology of aerated concrete and fly ash, which is applied in buildings, building components, building structures, etc., can solve the problems of poor seismic performance of walls, poor thermal insulation performance of walls and energy saving, and achieve improved seismic performance and energy saving sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

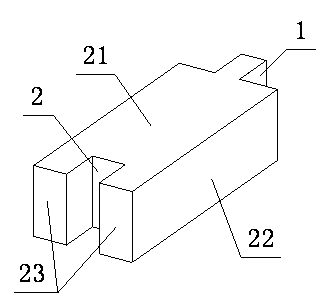

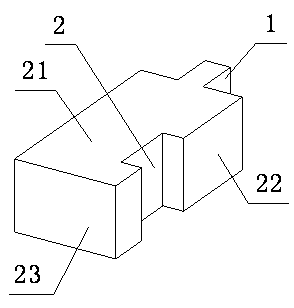

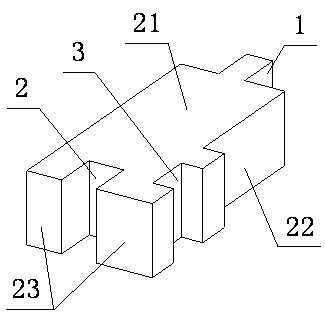

[0024] Using fly ash air-entrained concrete as raw material, the production process of fly ash air-entrained concrete blocks is adopted, according to figure 1 figure 2 image 3 Figure 4 As shown, the one-shaped fly ash aerated concrete concave-convex block, the right-angle fly ash aerated concrete concave-convex block, the double concave-convex fly ash aerated concrete block and the double convex-concave pulverized coal Ash aerated concrete block. Using these four kinds of blocks to build the wall, the first skin of the wall is built like Figure 5 As shown, the masonry of the second skin of the wall is as follows Image 6 As shown, the masonry of the third skin of the wall is as follows Figure 7 As shown, the cycle goes back and forth, and the elevation of the wall masonry is as follows Figure 8 As shown, the three-dimensional view of the wall masonry is shown in Figure 9 As shown; the masonry of the first skin of the wall corner is as follows Figure 10 As shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com