Disassembly and assembly floor

A floor and bottom plate technology, applied in the field of construction, can solve the problems of high replacement cost, difficult floor disassembly and replacement, easy water seepage, etc., and achieve the effect of low replacement cost and easy replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

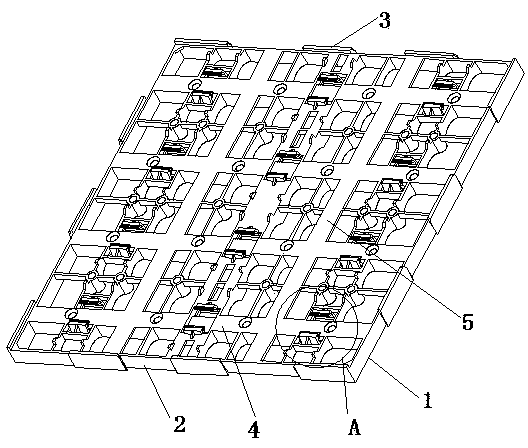

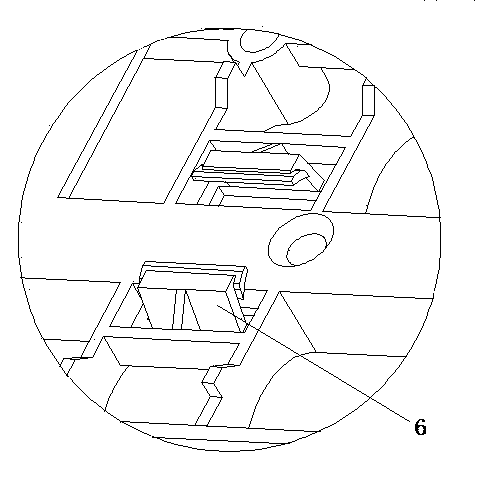

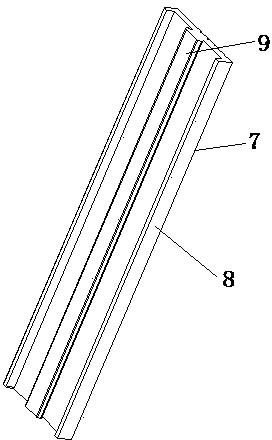

[0019] Example: as attached figure 1 , with figure 2 And attached image 3 As shown, a disassembled floor includes a floor 7. A square bottom plate 1 is installed on the bottom of the floor. Buckles 3 and slots 2 are respectively provided on the outer sides of the bottom plate. The buckles are square inserts, and the slots are square. The socket, the cutting strip and the socket are matched, and four horizontal support bars 4 and two vertical support bars 5 are arranged in the bottom plate. A clip 6, the center of the bottom of the floor is provided with an insert 9, the clip cooperates with the insert, and the both sides of the floor are provided with fastening strips 8, and the dismountable floor is formed by the horizontal insertion of four floor plates by each base plate.

[0020] The bottom of the detachable floor is provided with a bottom plate, the bottom plate can be connected with another bottom plate through the four sides, and the floor is plugged into the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com