Buffer decompression starting device and novel single cylinder diesel formed by same

A technology for a starting device and a diesel engine, which is applied to a starting device with a manual crank, an engine element, and the starting of an engine, etc., can solve the problem that the starting force of the diesel engine is relatively large, which affects the wide use and popularization of the diesel engine, and the cost of auxiliary devices is high. problems, to achieve the effect of broad market application prospects, prominent substantive characteristics, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] The existing auxiliary starting devices for diesel engines have the problems of high cost, short service life and inconvenient operation, and lack of application on single-cylinder diesel engines.

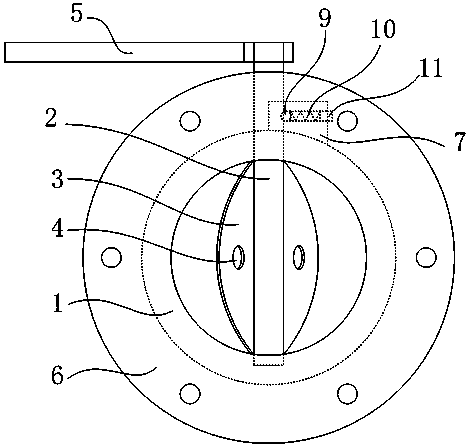

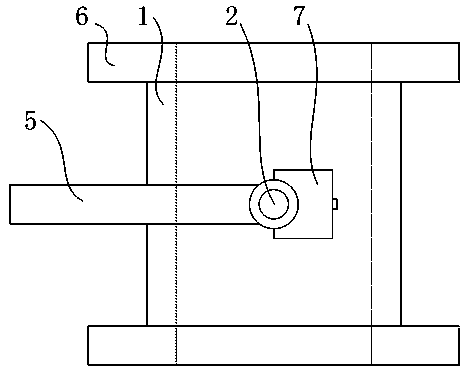

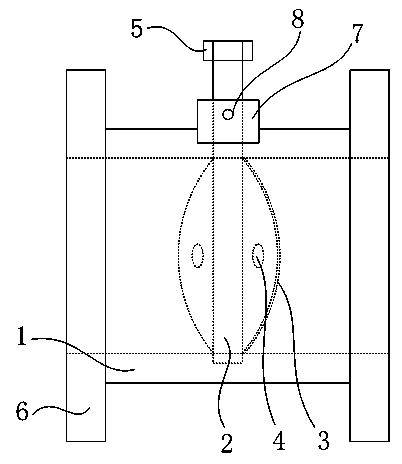

[0031] Such as Figure 1 to Figure 4 As shown, the buffer decompression starting device includes an intake pipe body 1 with connectors 6 at both ends, a central axis 2 set radially through the intake pipe body, located in the intake pipe body and matched with the inner cavity of the intake pipe and A choke plate 3 fixedly connected to the central shaft, at least one air intake hole 4 provided on the choke plate, and a rotary handle 5 provided outside the air intake pipe for controlling the rotation of the central shaft. A positioning mechanism for adjusting the position of the choke plate is provided at the position where the central axis is located outside the body of the air intake pipe.

[0032] Specifically, the positioning mechanism includes a positioning seat 6 that i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com