Point-contact pin-type force sensor

A load cell and point contact technology, applied in the direction of measuring force, instruments, measuring devices, etc., can solve the problems of weak carrying capacity of hollow structures, unstable measurement results, uneven load distribution, etc., and achieve strong carrying capacity and product reliability High and repeatable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

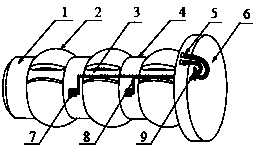

[0015] like figure 1 As shown, a point contact pin type force sensor includes a pin body 1 and a pin seat 6 located at one end of the pin body 1. Three drum-shaped bosses 2 are arranged in sequence on the axial direction of the pin body 1, and two adjacent The pin body between the drum-shaped bosses 2 is a sensing section 4, and a wire arrangement groove 3 is arranged on the outer peripheral surface of each drum-shaped boss, and a total of three wire arrangement grooves on each drum-shaped boss are arranged along the axis of the pin body. To be collinear, four resistance strain gauges 7 are evenly arranged on the outer peripheral surface of each sensing section 4, and each resistance strain gauge 7 is connected with a wire 8, and the wire 8 passes through the wire arrangement groove 3 and then passes through the pin seat 6. The lead hole 9 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com