Automatically-controlled torsion-bend tester

A bending testing machine, automatic control technology, applied in the direction of electrical program control, program control in sequence/logic controller, testing of mechanical parts, etc., can solve the problems of low degree of automation and low precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

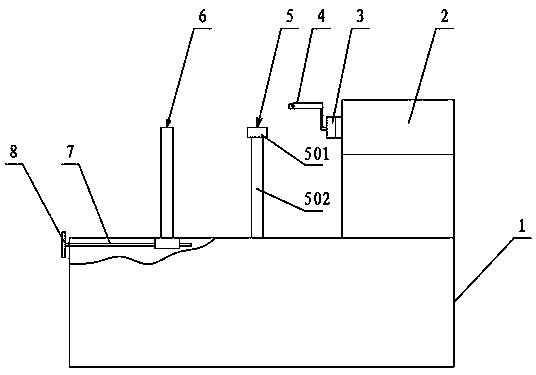

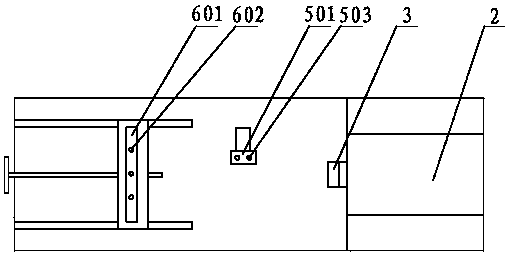

[0020] Hereinafter, the present invention will be further explained in conjunction with the accompanying drawings of the specification.

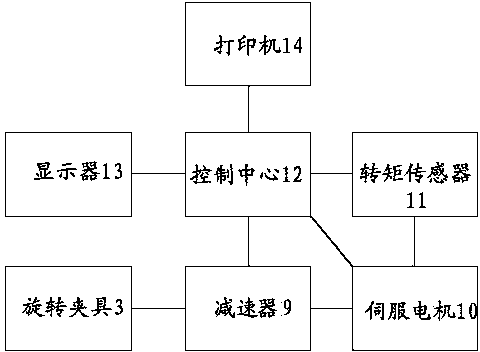

[0021] Such as Figure 1-4 As shown, an automatic control torsion bending test machine includes a frame table 1 on which a rotating fixture control box 2, a bending fixing fixture 5 and a torsion fixing fixture 6 are sequentially arranged. The rotating fixture control box 2 is provided with a servo motor 10 and a reducer 9 for controlling the speed of the servo motor 10. Among them, the reducer 9 is preferably a planetary cycloid reducer, which has the characteristics of uniform loading, stability, no impact, and accurate data acquisition and control. The output shaft of the servo motor 10 is also fixedly provided with a rotating clamp 3 and a torque sensor 11. The rotating clamp 3 is used to clamp light and cables, and the torque sensor 11 is used to measure parameters such as torque and torsion angle. During installation, the heights of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com