Testing device for measuring soil resistance in motion process of buried submarine pipeline

A motion process, submarine pipeline technology, applied in soil material testing, material inspection products, etc., can solve the problems of inability to deform freely, affecting the safe operation and use of submarine pipelines, etc., to achieve convenient observation, excellent tensile and flexural performance, Cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

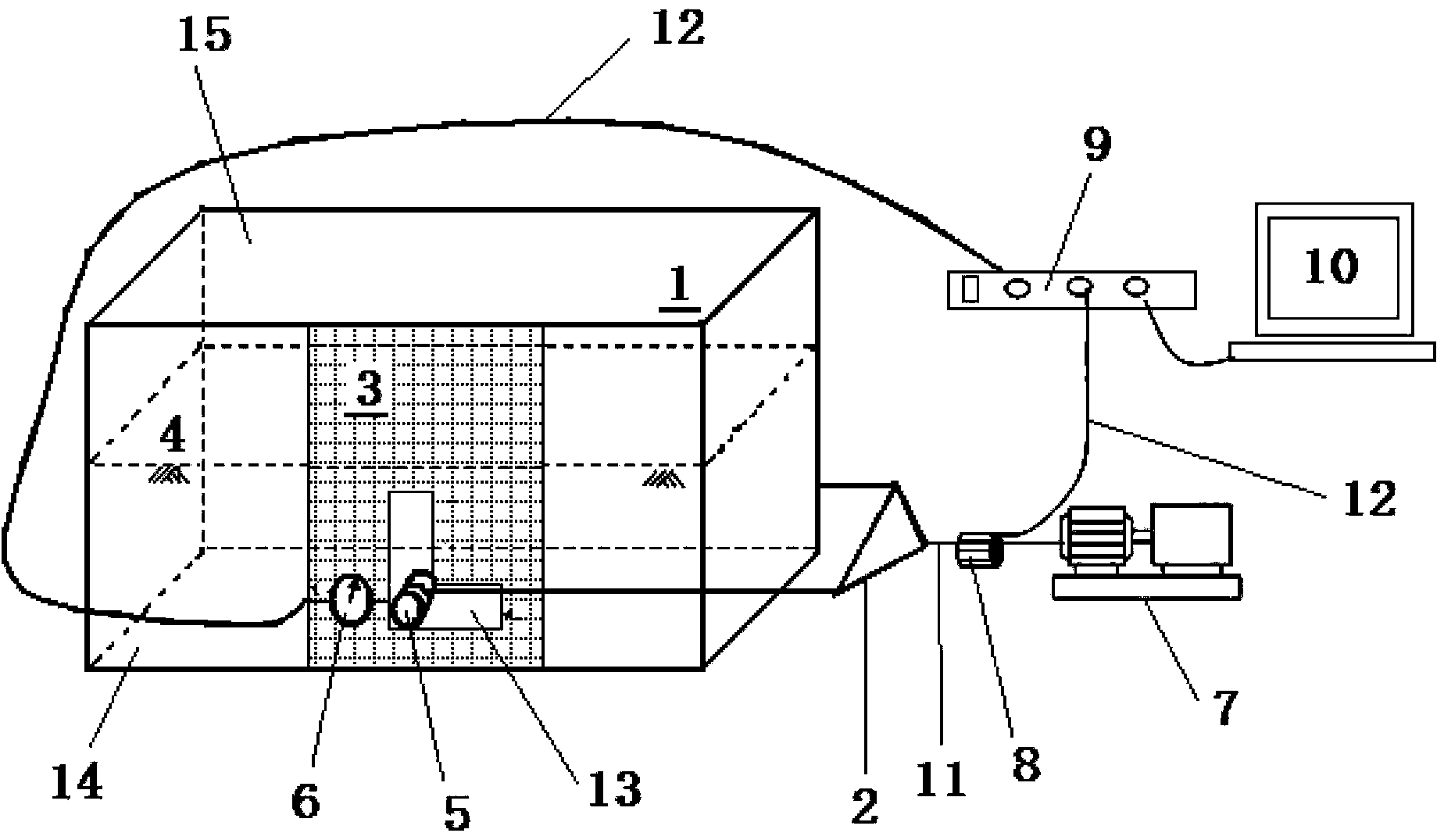

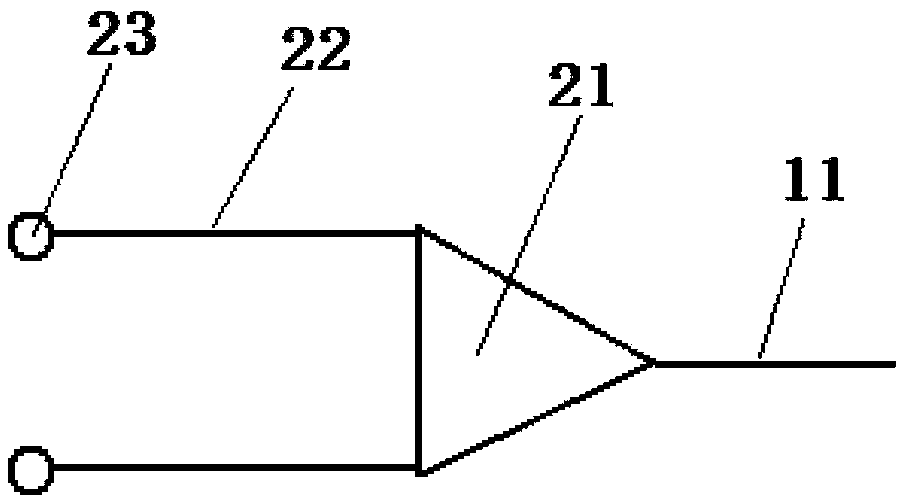

[0028] Take the 80mm diameter test pipeline in the sandy soil along the axial, horizontal and axial three directions of soil resistance test process as an example. The test process can be divided into three stages, which are described as follows:

[0029] 1. Test preparation

[0030] The preparations for the resistance test in three directions of sand and soil can be divided into three steps: filling sand and compacting, digging trenches and burying pipes, and connecting test devices and instruments.

[0031] (a) Sand packing compaction. Fill the sand into the test tank in every 10cm layer. After each filling, the sand is compacted with a roller, and the density of the layer is measured by the ring knife method. The density of the sand is controlled at about 50%. Filling is repeated in this way until the predetermined elevation is reached.

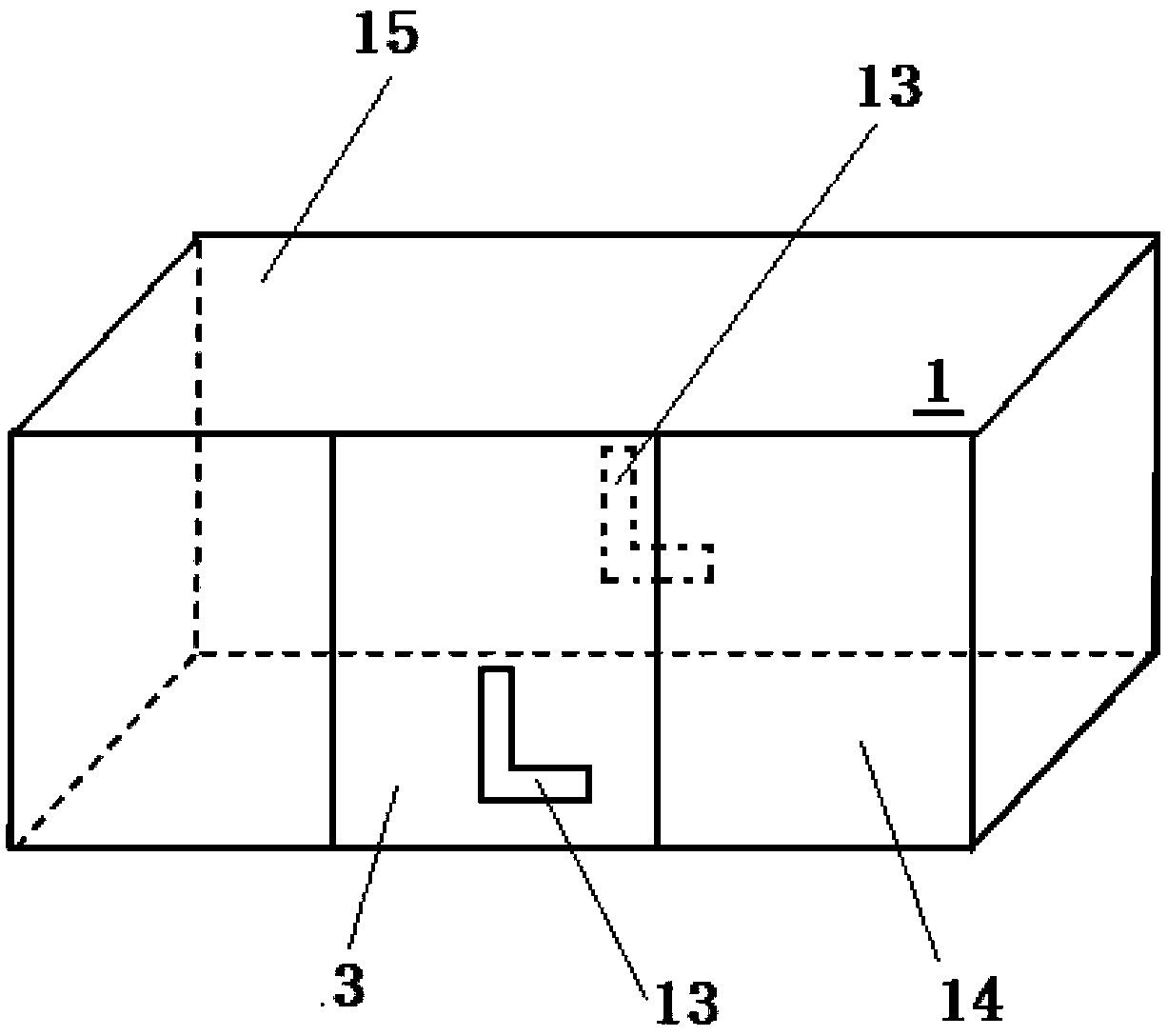

[0032] (b) Excavation and pipe laying. The filled sand is excavated to the L-shaped channel of the test tank according to the slope o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com