Multilayer tipping-bucket rain gauge possessing stepped controlled release water injection funnel

A tipping bucket rain gauge and cascade controlled release technology, which is applied in the field of meteorological and hydrological instruments, can solve the problems that the accuracy cannot reach the accuracy level of general hydrological and meteorological instruments, and can not reduce the measurement error of the measuring tipping bucket more effectively. Achieve the effect of improving measurement accuracy and reducing measurement error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

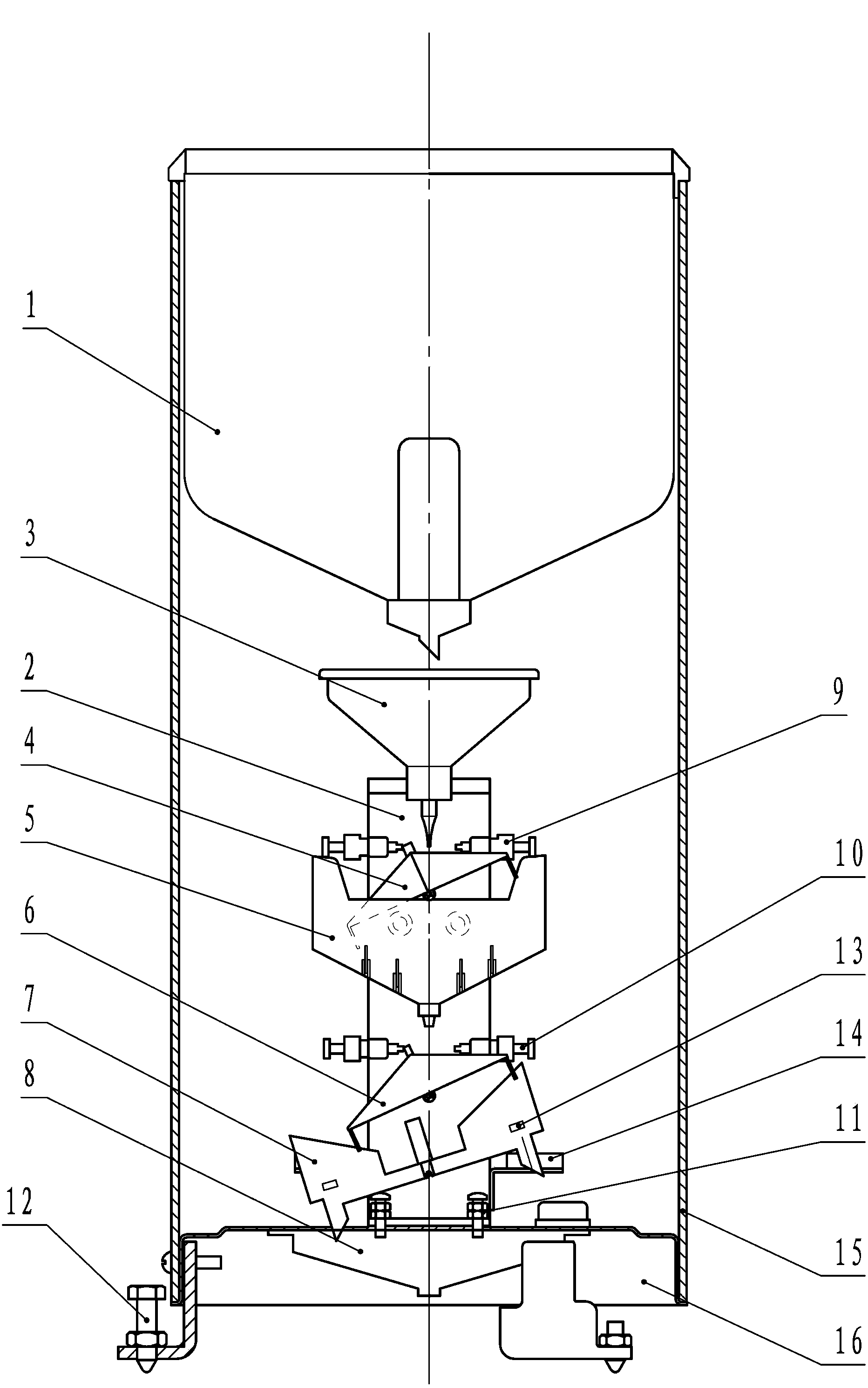

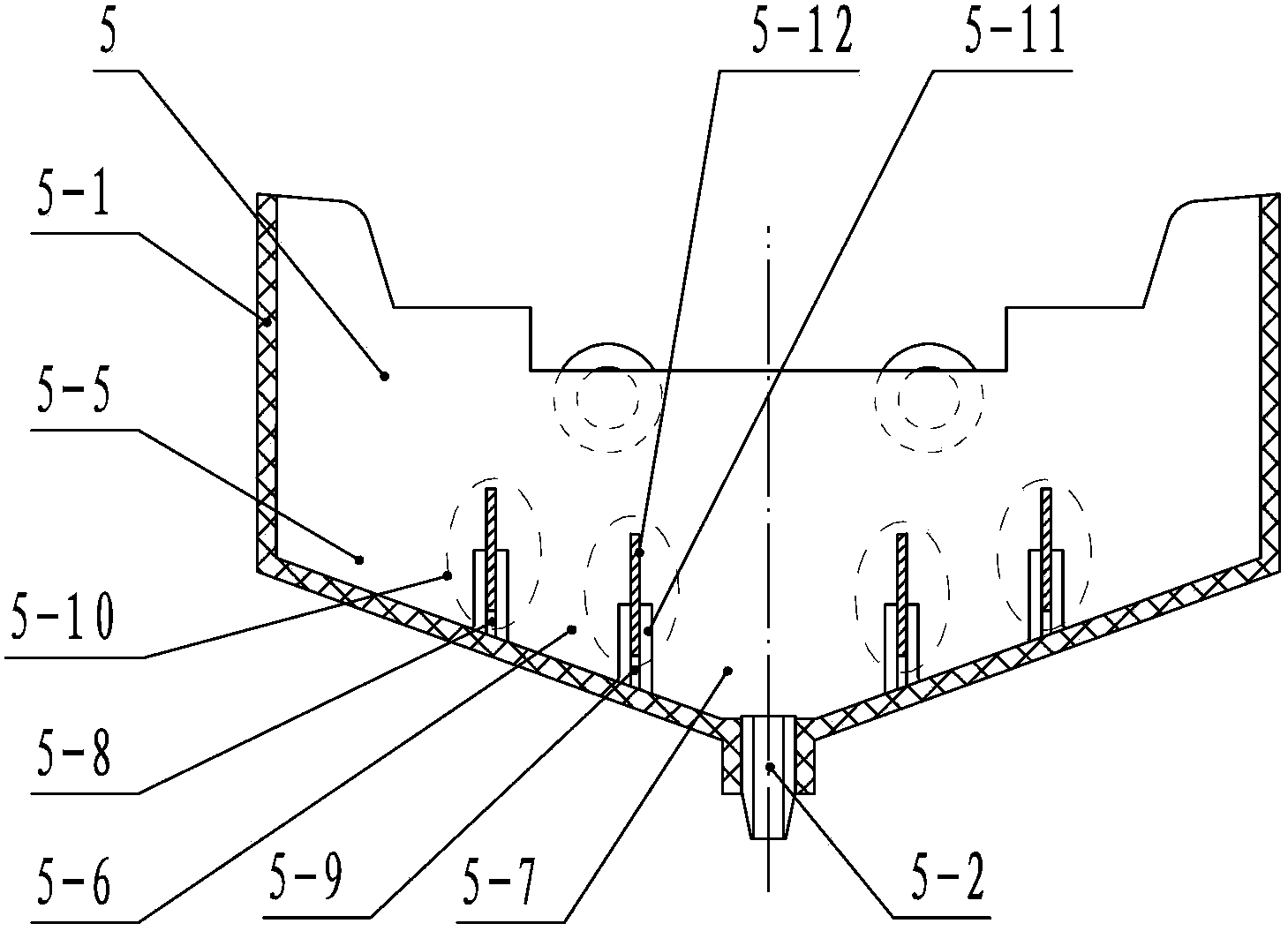

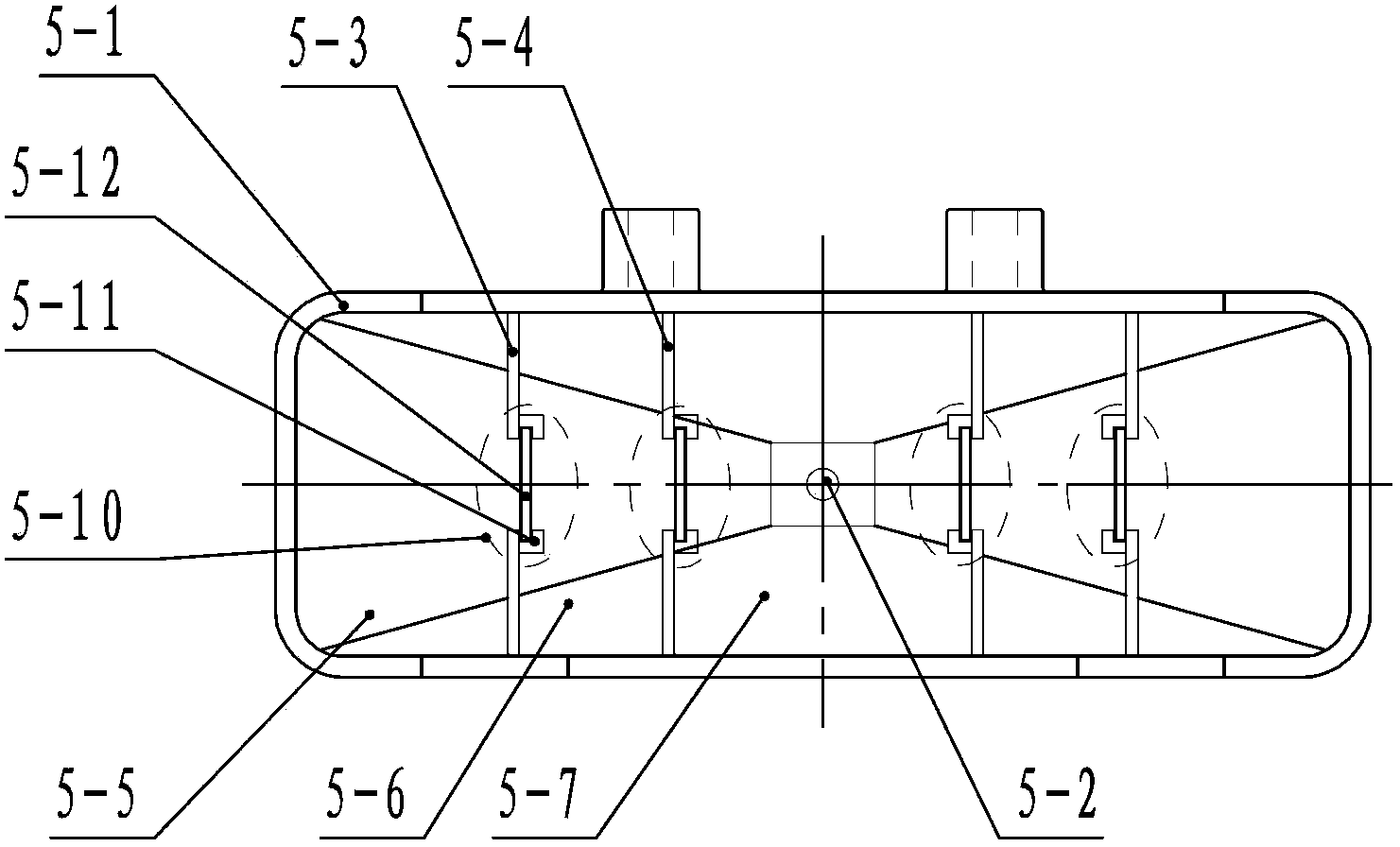

[0024] Such as figure 1 , figure 2 , image 3 Shown: a multi-layer tipping bucket rain gauge with a step-controlled release water injection funnel, including a base 16, an outer cylinder 15, a rain receiving port assembly 1, a bracket 2, an upper water injection funnel 3, an upper tipping bucket 4, a measuring tipping bucket 6, and a counting bucket Tipping bucket 7, drainage funnel 8, upper tipping bucket inclination adjusting device 9, metering tipping bucket inclination adjusting device 10, counting tipping bucket inclination adjusting device 11 and leveling device 12. A permanent magnet 13 is arranged on the counting bucket 7 , and a reed switch 14 is arranged on the support 2 . It is characterized in that: a step control release water injection funnel 5 is set between the metering tipping bucket 6 and the upper tipping bucket 4; the funnel base 5-1 of the step control release water injection funnel 5 is a conical shell that is straight up and down, and the body of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com