Electrochromic glass, hollow glass and preparation methods thereof

A technology of electrochromic glass and electrochromic layer, applied in nonlinear optics, instruments, optics, etc., can solve problems such as low yield rate and inability to fully release production capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

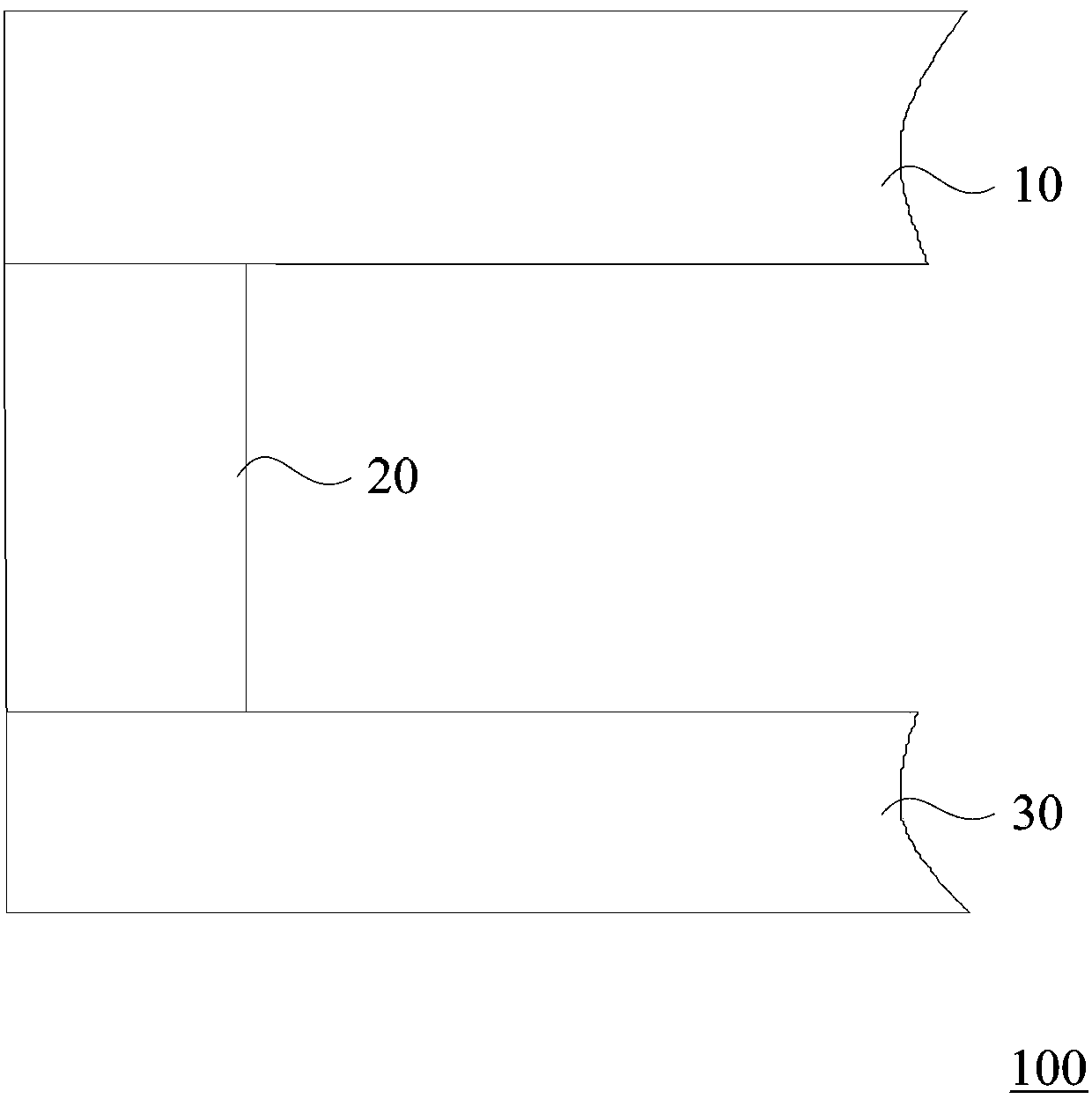

[0043] In order to describe the preparation method of the insulating glass 100 in detail, the electrochromic glass 10 formed by coating a large plate (large area) glass substrate is taken as an example to illustrate the preparation process of the insulating glass 100, which includes the following steps.

[0044] 1. Large plate (large area) substrate coating

[0045] Combined with the current large-area glass coating process, after the glass substrate is cleaned and dried, it enters the vacuum coating line, is coated, and leaves the vacuum coating line to complete the large-scale coating process. The coating process of each step is as follows:

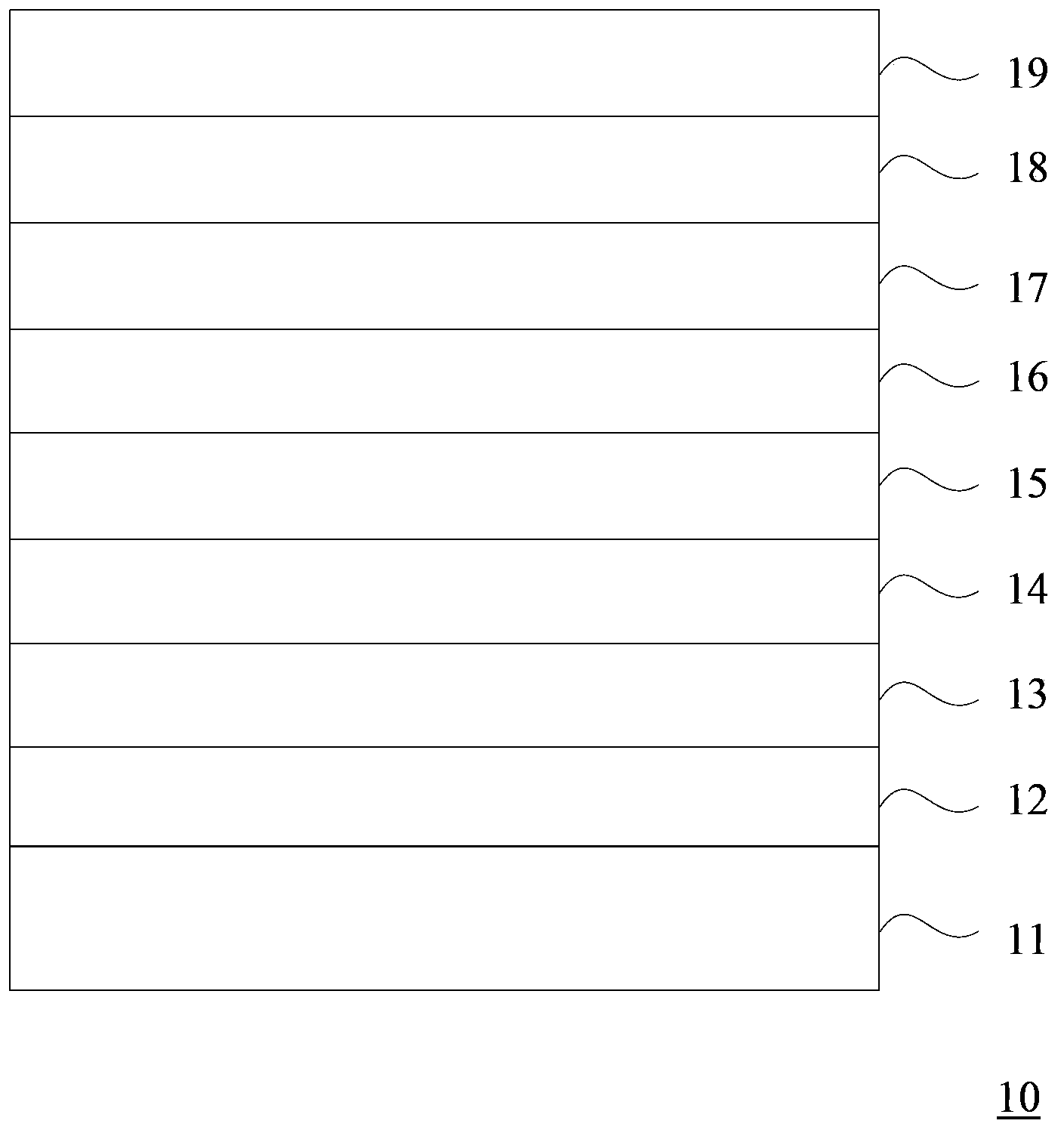

[0046] 1. Deposit an ion barrier layer on a large-area flat substrate, and the material of the ion barrier layer can be SiO x ;

[0047] 2. A bottom transparent conductive layer is deposited on the ion barrier layer, and the material of the bottom transparent conductive layer can be AZO;

[0048] 3. Deposit an electrochromic layer on...

specific Embodiment

[0074] An electrochromic glass according to an embodiment of the present invention, the film layer structure is: "substrate / SiO x / AZO / WO 3 / LiW x o y / NiV x o y / LiNi x V y o x / AZO / SiO x ”, where the ion barrier SiO x The thickness of the bottom transparent conductive layer AZO is 50nm, the thickness of the bottom transparent conductive layer AZO is 200nm, the electrochromic layer WO 3 The thickness is 500nm, the auxiliary electrode layer NiV x o y The thickness of the transparent conductive layer is 300nm, the thickness of the top transparent conductive layer is 200nm, the thickness of the protective layer is 50nm, the surface resistance of the two transparent conductive layers is about 40Ω / □, and the thickness of the first and second lithium ion conductor layers is about tens of nanometers.

[0075] The method for preparing this electrochromic glass and the steps for preparing insulating glass with this electrochromic glass are sequentially: coating a large plat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com