Steel pipe sizing mill capable of adjusting pipe diameter size

A sizing machine and size technology, applied in metal rolling and other directions, can solve the problems affecting the surface quality and straightness of seamless steel pipes, difficult to improve the quality of hot-rolled seamless steel pipes, and complex processing technology of the frame body, etc. The effect of surface quality and straightness, simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

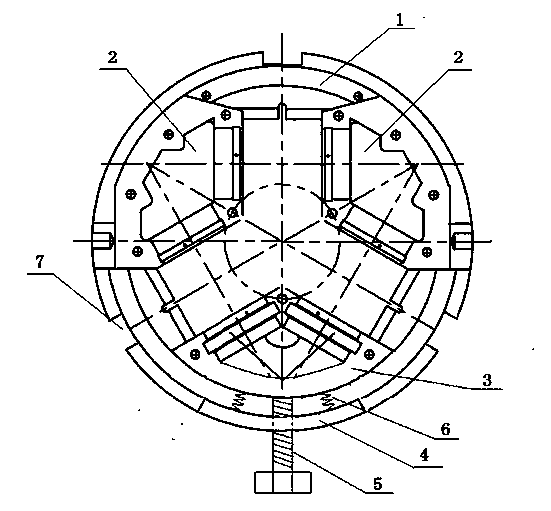

[0011] Such as figure 1 as shown,

[0012] The technical solution of the present invention is: a steel pipe sizing machine with adjustable pipe diameter, including a cylindrical frame body 1, two fixed roll parts 2 and a movable roll part 3 are installed on the frame body 1 , the axes of the three roll parts form an equilateral triangle, and the limit baffle 4 is installed on the frame body 1 outside the movable roll part 3 . Threaded through hole, the jack wire 5 passes through the limit baffle 4 and contacts the outer wall of the movable roll part 3, and several springs 6 are connected between the movable roll part 3 and the limit baffle 4. Several positioning slots 7 are evenly distributed on the outer circumference of the frame body 1 .

[0013] In this embodiment, three positioning grooves 7 are provided on the outer circumference of the frame body 1, and the positioning grooves 7 are arranged between every two roll parts.

[0014] The working method and advantages of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com