Method of quickly identifying thermal state characteristics of machine tool main shaft

A technology of machine tool spindle and characteristics, which is applied in the testing of mechanical parts, the testing of machine/structural parts, metal processing mechanical parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

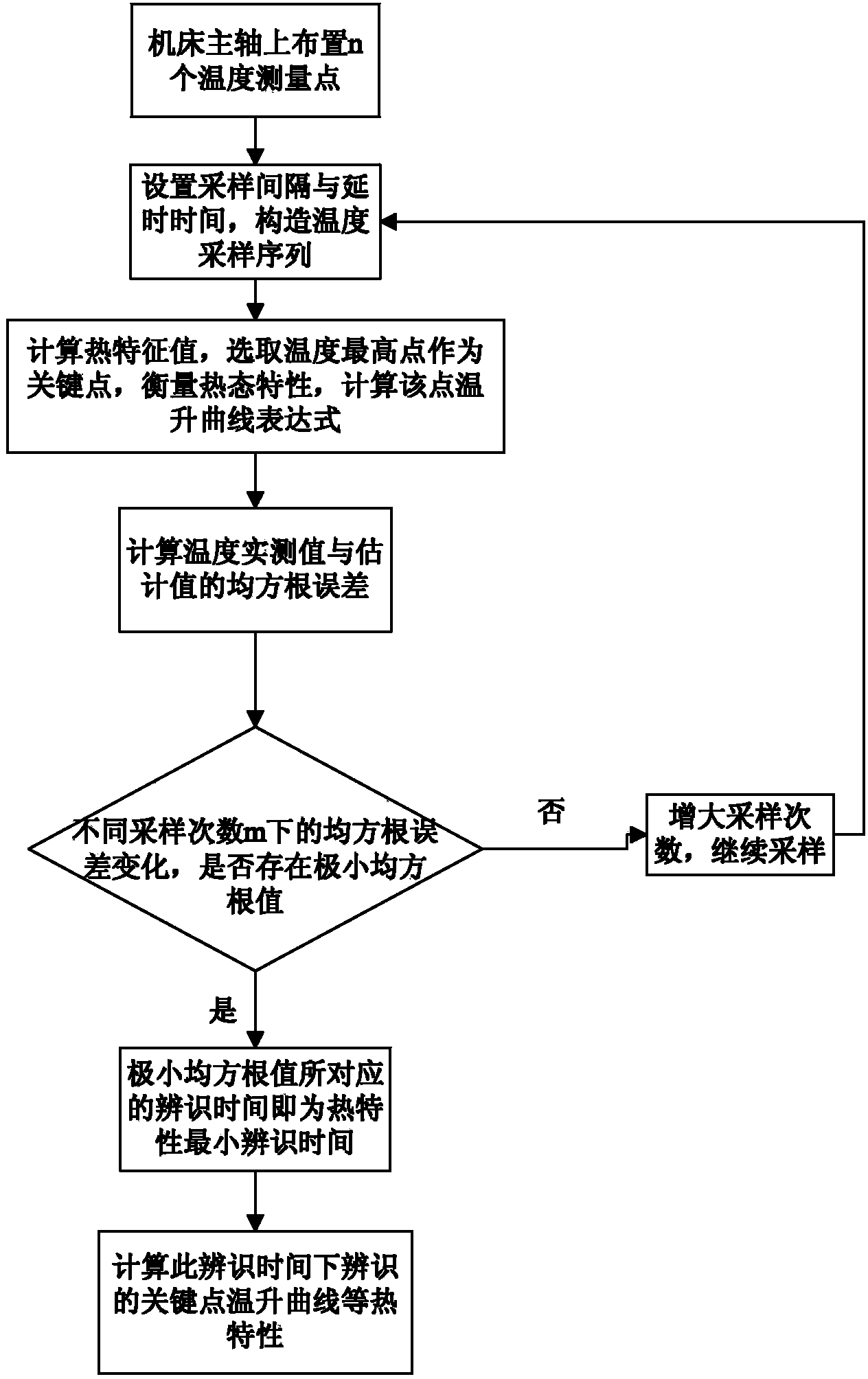

Method used

Image

Examples

Embodiment 1

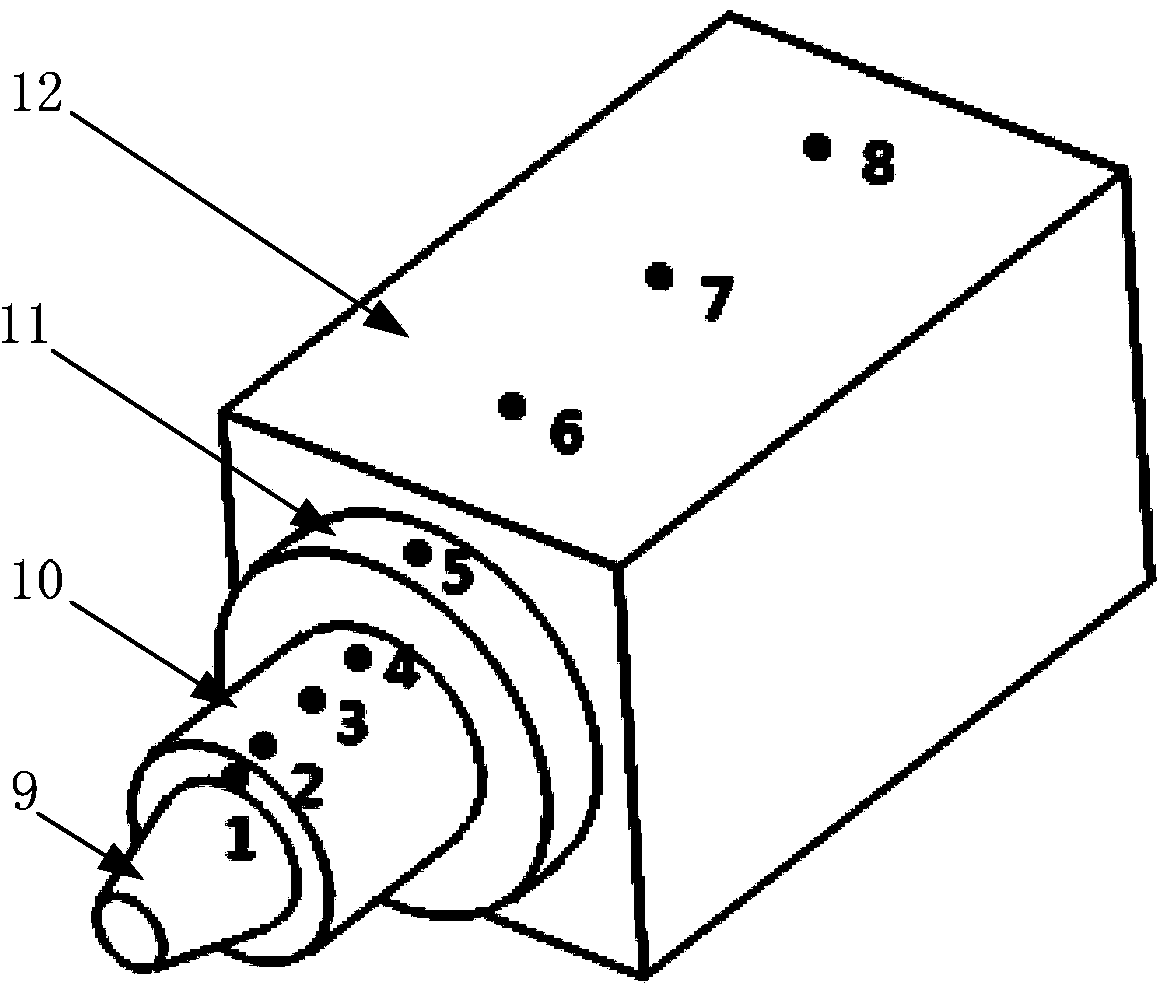

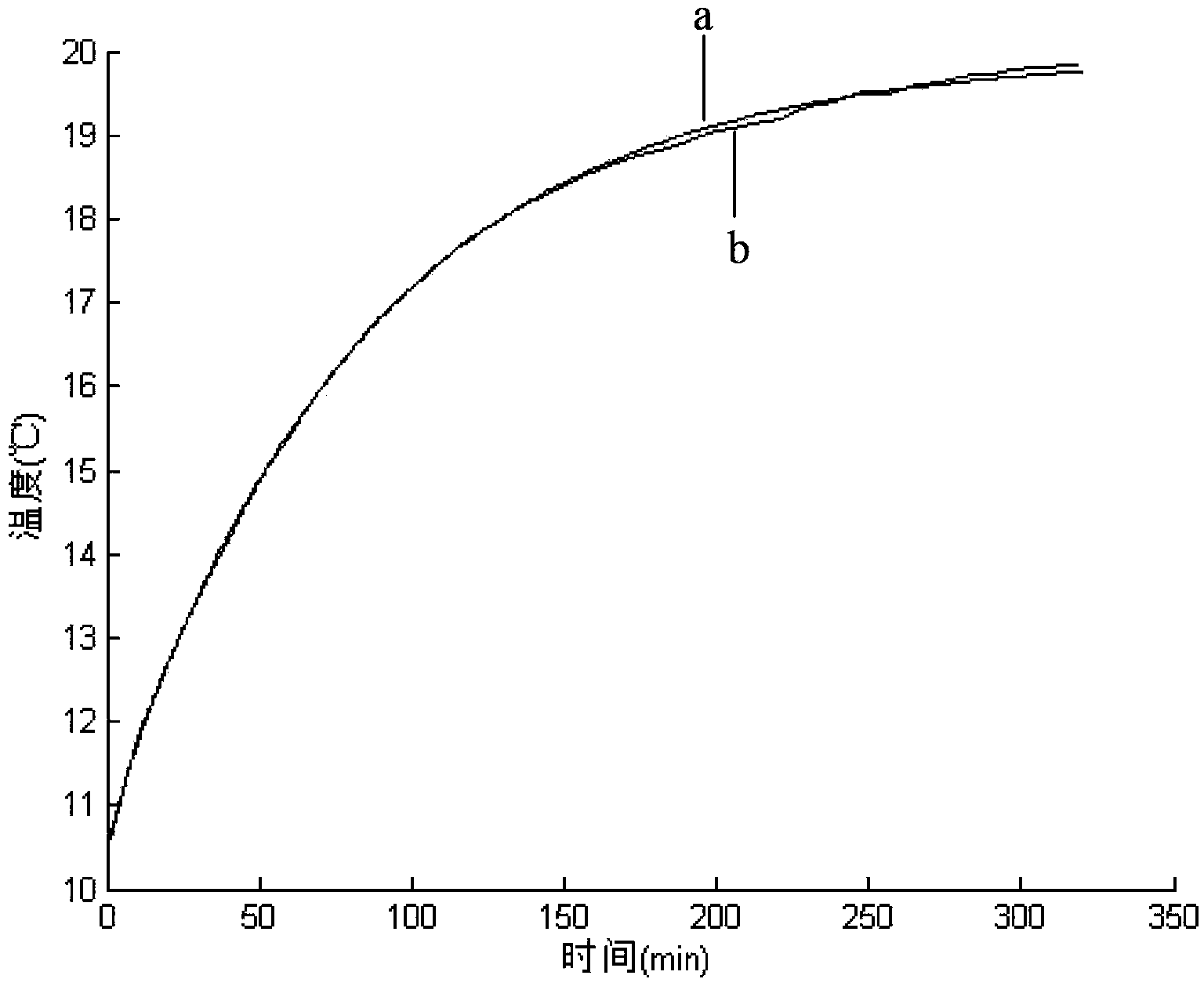

[0126] Such as figure 2 As shown, thermal characteristic identification is performed on the spindle of a vertical machining center, and temperature sensors 1, 2, 3, 4, 5, 6, 7, and 8 are arranged along the axial direction of the spindle of the machine tool to form different temperature measurement points, namely Set 8 temperature measuring points, among which, 9 is the mandrel, the temperature sensor 1 is located on the front end of the bearing housing 10, the temperature sensors 2, 3, 4 are located on the outer circumference of the bearing housing 10, and the temperature sensor 5 is located on the outer circumference of the flange 11 , The temperature sensors 6, 7, 8 are located on the outer surface of the headstock 12. The temperature sensor 3 is located on the outer circumferential surface of the bearing seat 10 (at the front bearing of the spindle), and has the highest temperature rise, and has a great influence on the thermal deformation error of the tool tip point. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com