Mold opening method capable of shortening product mold manufacturing flow

A product and mold technology, which is applied in the field of mold opening that can shorten the product mold making process, can solve the problems of frequent changes, multiple revisions, and long time, and achieve the effects of shortening mold opening time, improving process efficiency, and increasing practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The detailed description and technical content of the present invention will be described as follows with the accompanying drawings, but the attached drawings are only for illustration purposes and are not intended to limit the present invention.

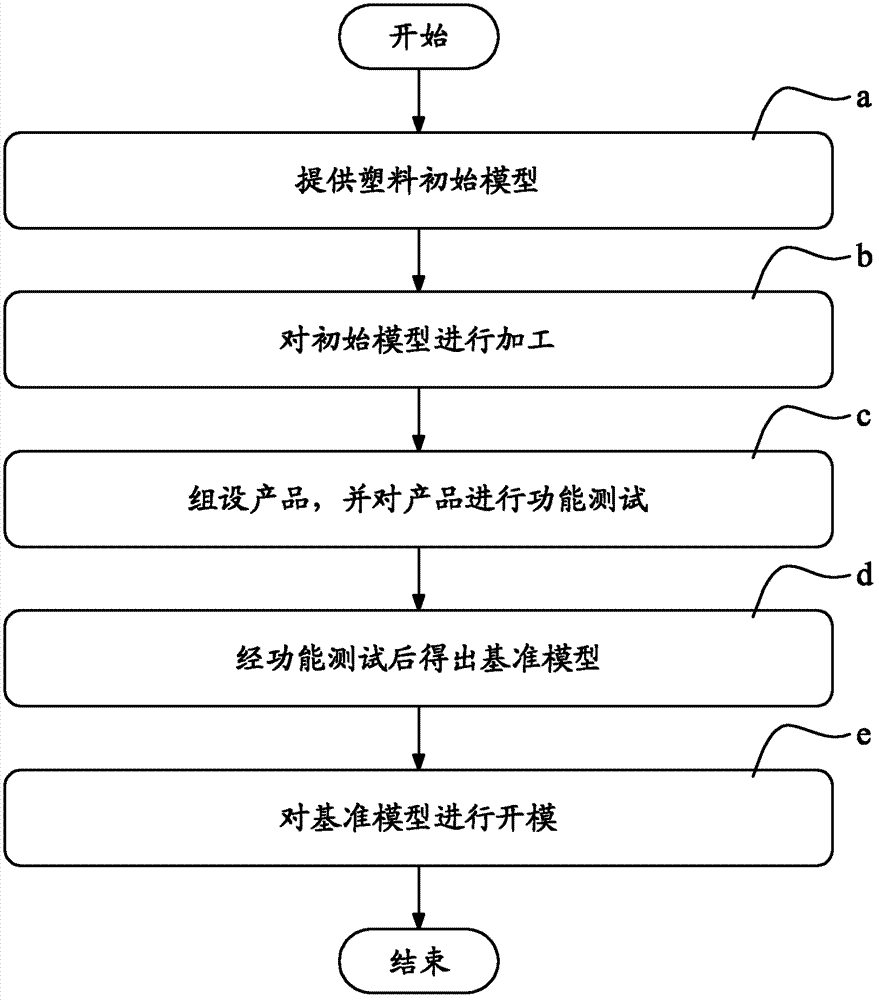

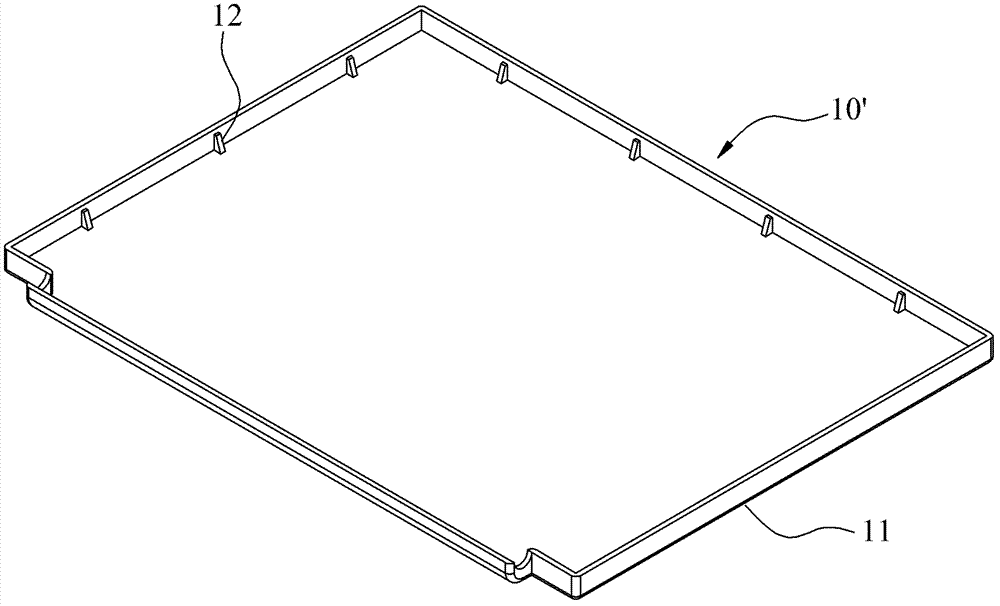

[0023] Please also refer to Figure 1 to Figure 3 , are respectively the flowchart of the mold opening method that can shorten the product mold manufacturing process of the present invention, the schematic diagram of the initial model before processing, and the schematic diagram of the initial model after processing. First, a plastic initial model 10 is provided (step a); preliminary processing is carried out to the initial model 10 to form the structure of the product (step b); the product is assembled, and the product containing the initial model 10 is subjected to a functional test (step c); Then, obtain the benchmark model 10' after the function test (step d), that is, decide whether to reprocess the initial model 10 acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com