A Double Bearing Weight Reduction Method for Full Suspension Rear Axle

A full-suspension, rear axle technology, applied to axles, wheels, brakes, etc., can solve the problems of low concentricity accuracy between axle housing and transmission half-shaft, increased transmission resistance and loss, and reduced mechanical movement efficiency. The effect of weight reduction is obvious, the half shaft is prevented from breaking, and the safety factor is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

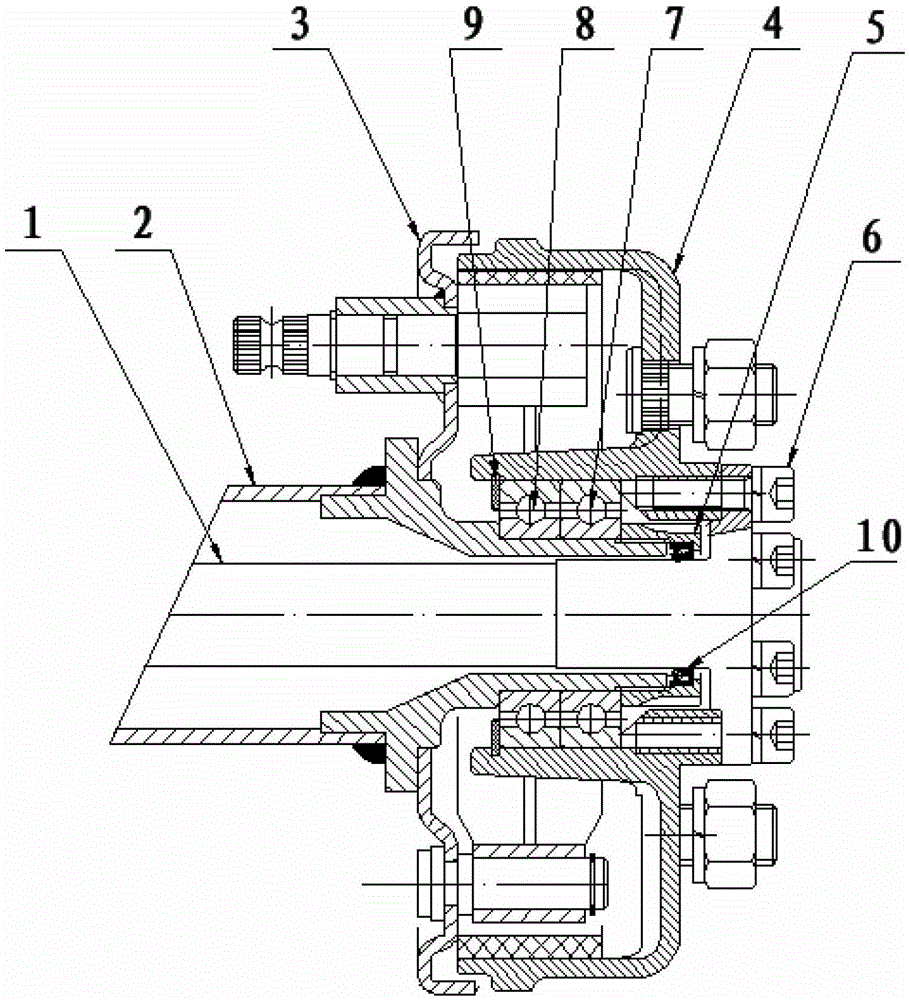

[0016] When the three-wheeled motorcycle for motorcycle bears weight, all gravity acts on the top of the brake drum assembly 4, and after the brake drum assembly 4 is stressed, the gravity is transmitted downward to the entire brake drum assembly 4, and the locking round nut assembly 5 and The sealing ring 10 fixes the brake drum assembly 4 on the transmission half shaft 1, and the brake drum assembly 4 transfers the gravity to the center to the bearing 1 7 and bearing 2 8 arranged side by side, and the outer casing of the bearing 1 7 and bearing 2 8 is After the force is transferred to the inner sleeve of the bearing through the roller during the rotation of the bearing, the inner sleeve of the first bearing 7 and the second bearing 8 will transfer and disperse the force to the axle housing 2, and the axle housing 2 is on the outer periphery of the transmission half shaft 1, The axle housing 2 bears all the gravity of the three-wheeled motorcycle, and the transmission half sha...

Embodiment 2

[0018] Half-shaft bolts 6 fix the brake drum assembly 4 on the end face of the transmission half-shaft 1 , so that the brake drum assembly 4 is tightly pressed against the first bearing 7 and the second bearing 8 .

Embodiment 3

[0020] The inner sleeves of the first bearing 7 and the second bearing 8 are tightly fit with the axle housing 2, and the hole-type retaining ring 9 prevents the bearing 7 and the second bearing 8 from loosening or slipping.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com