Brand-new intelligent belt conveyer

A belt conveyor, intelligent technology, used in conveyors, conveyor objects, conveyor control devices, etc., can solve the problem of single adjustable, can not meet the requirements of on-site use, can not meet the high efficiency of modern production, batch and no order requirements and other issues, to achieve the effect of adapting to diversity and improving the level of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

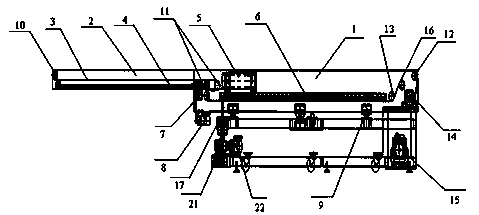

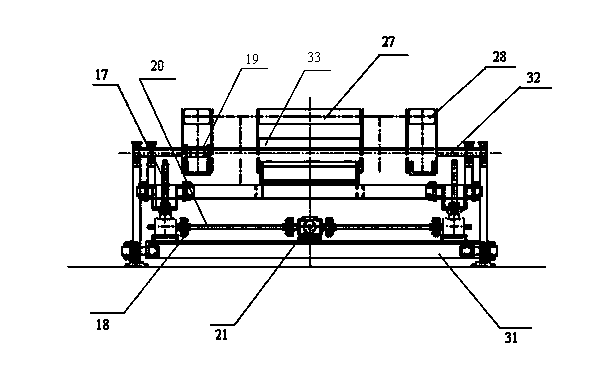

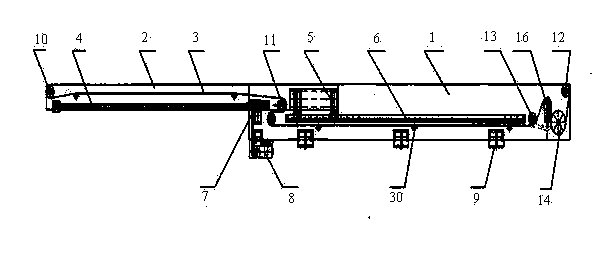

[0028] Illustrate the present invention below in conjunction with accompanying drawing

[0029] The main driving motor (15) is installed at the end of the base of the frame of the belt conveyor, and the intelligent system control master station is connected with the upper computer through the DP-DP coupler and the bus.

[0030] In the part of the telescopic transmission device, the fixed frame body (1) and the telescopic frame body (2) are connected by linear bearings and guide rails, the telescopic frame body (2) is fixed on the telescopic frame body fixing seat (5), and the telescopic frame body The body fixing seat (5) is installed on the slider of the linear guide rail (6), the chain transmission device (7) is fixed on one end of the ball screw (4), and the length driving machine (8) is connected with the chain transmission device (7). The telescoping device has several towing rollers (30) supporting the transport belt (4), and is also provided with a head redirecting roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com