Concrete elevation gradient controller

A concrete and controller technology, applied in the field of controllers, can solve the problems that cast-in-place concrete is difficult to meet the geometric size design requirements, cannot control the elevation and slope of the concrete surface, and the effect of concrete construction control is low, and achieves the reduction of financial and human resources. The effect of input, easy assembly, and smooth drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

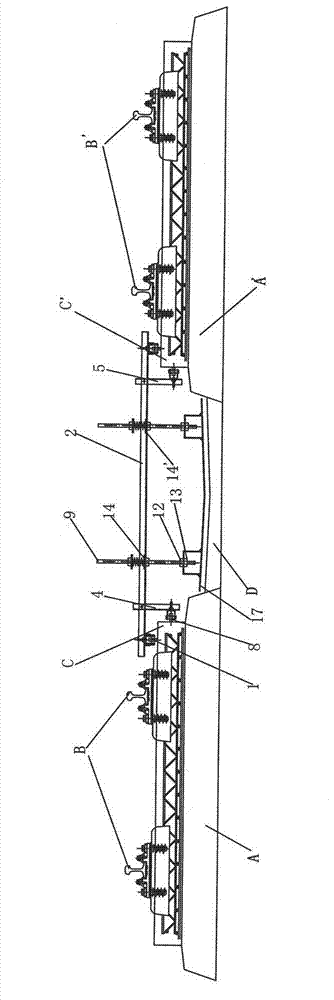

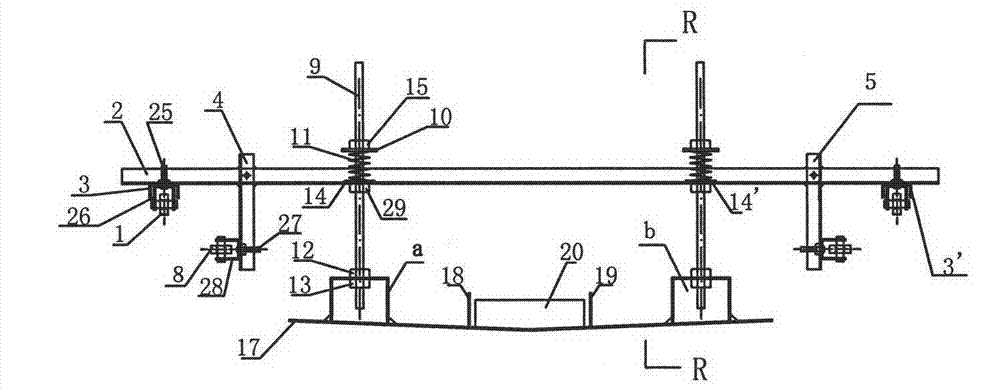

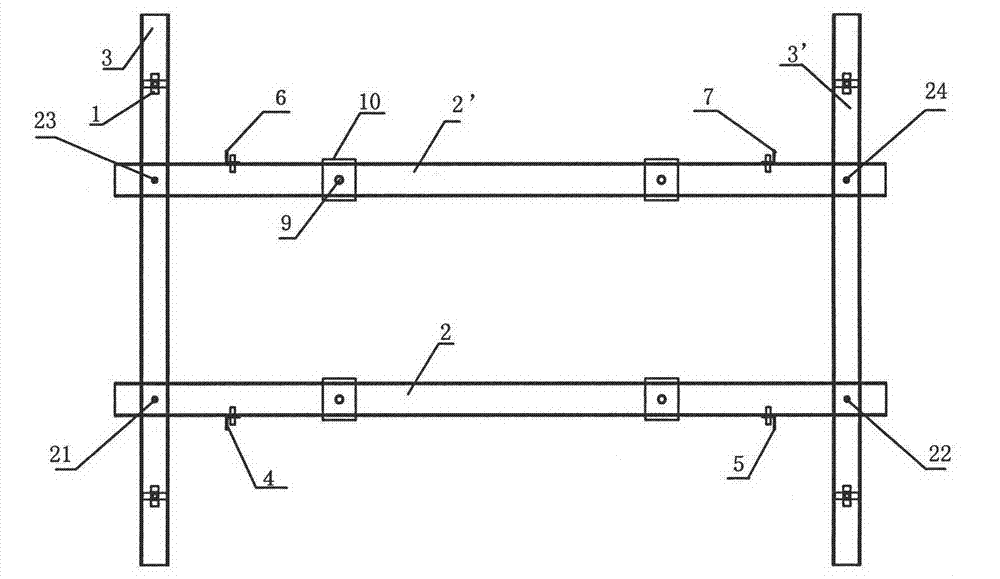

[0016] exist figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 In the shown embodiment, four first column seats a, second column seats b, third column seats c, fourth column seats c, and four are respectively welded on the "V" shaped vibrating steel plate 17. Column seat d; the horizontal distance between the first column seat a and the second column seat b, the third column seat c and the fourth column seat d on the "V"-shaped vibrating steel plate is 1200mm, and the vertical distance is 800mm; the height of the four columns is 850mm , diameter is 25mm elevation control column 9 lower ends and the top are provided with screw thread, with first nut 12 and second nut 13 respectively four elevation control columns are installed and fixed on the first column base a, the second column base b, the second column base On three column seats c, the 4th column seat d; With the 3rd nut 15 and the 4th nut 29 backing plate 10, damping spring 11, spring seat 14 are sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com