Speedy tunneling method for gas drainage roadway

A gas drainage and gas roadway technology is applied in the field of rapid excavation of gas drainage roadways, which can solve the problems of delaying mine production progress, lag in excavation, affecting coal mine benefits, etc., and achieve the effect of realizing mine safety and early production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

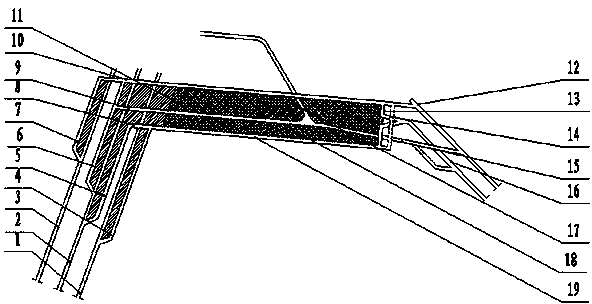

[0017] The present invention will be further described below in conjunction with accompanying drawing.

[0018] like figure 1 As shown, the rapid excavation method of the gas drainage roadway of the present invention comprises the following steps:

[0019] a: Excavate return air inclined shaft 1, track inclined shaft 2 and transport inclined shaft 3 from the ground, and then excavate return air stone gate 4 and track stone gate at the positions corresponding to return air inclined shaft 1, track inclined shaft 2 and transport inclined shaft 3 5 and track level lane 6, transport stone gate 7; damper 8 is set on track level way 6, can make the air intake and return air not mix with each other, and prevent short circuit of wind flow;

[0020] b: Two adits are developed from the boundary of the mine field: the measure well transport adit 12 and the measure well return air adit 16, and then dig out the auxiliary cutting hole 14, a part of the cutting hole 13, and the measure well ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com