A method for re-mining extra-thick coal seam to stop mining line coal pillar

A technology of extra-thick coal seam and stop-mining line is applied in the field of re-mining of extra-thick coal seam with stop-mining line coal pillar, which can solve problems such as coal loss of stop-mining line coal pillar, so as to shorten excavation time, realize safe production, and reduce excavation engineering. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

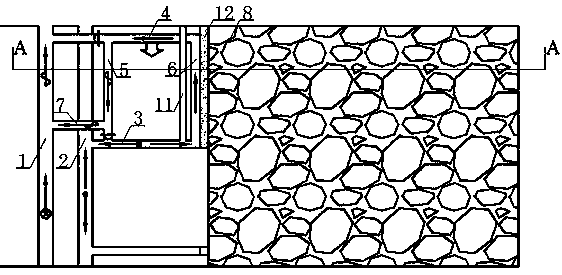

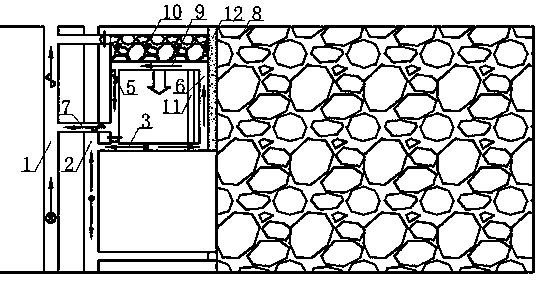

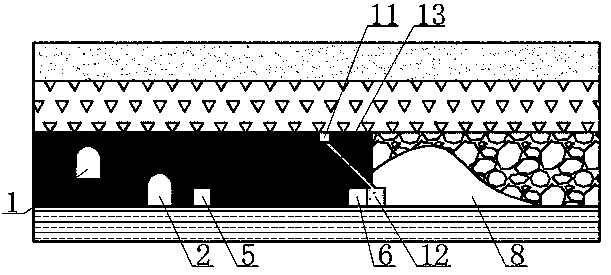

[0038] In a later production mine, the coal pillar and coal seam has an average thickness of 13.76m, and the working face usually has a dedicated roof gas drainage roadway. The width of the coal pillars on the stop line of the working face is about 230m, and the amount of coal pillars is huge. Since the main mining area of the mine has been stopped, the coal pillars in the area must be re-mined.

[0039] Determination of the position of the coal pillar re-mining roadway. Combining the mine geological data, according to the limit equilibrium theory of surrounding rock, the range of supporting pressure distribution and using FLAC 3D Numerical simulation software determines the reasonable location selection range of the coal pillar re-mining face (transport along the coal pillar re-mining face 6 and the coal pillar re-mining face track 5), and then determine the coal pillar according to the mine production data The specific location of the mining roadway in the re-mining face.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com