System and method for increasing fuel economy of a vehicle including a SCR catalyst

A technology of SCR catalytic converter and exhaust system, which is applied in the direction of charging system, combustion engine, machine/engine, etc., and can solve the problems of engine fuel economy lower than expected, engine fuel economy reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

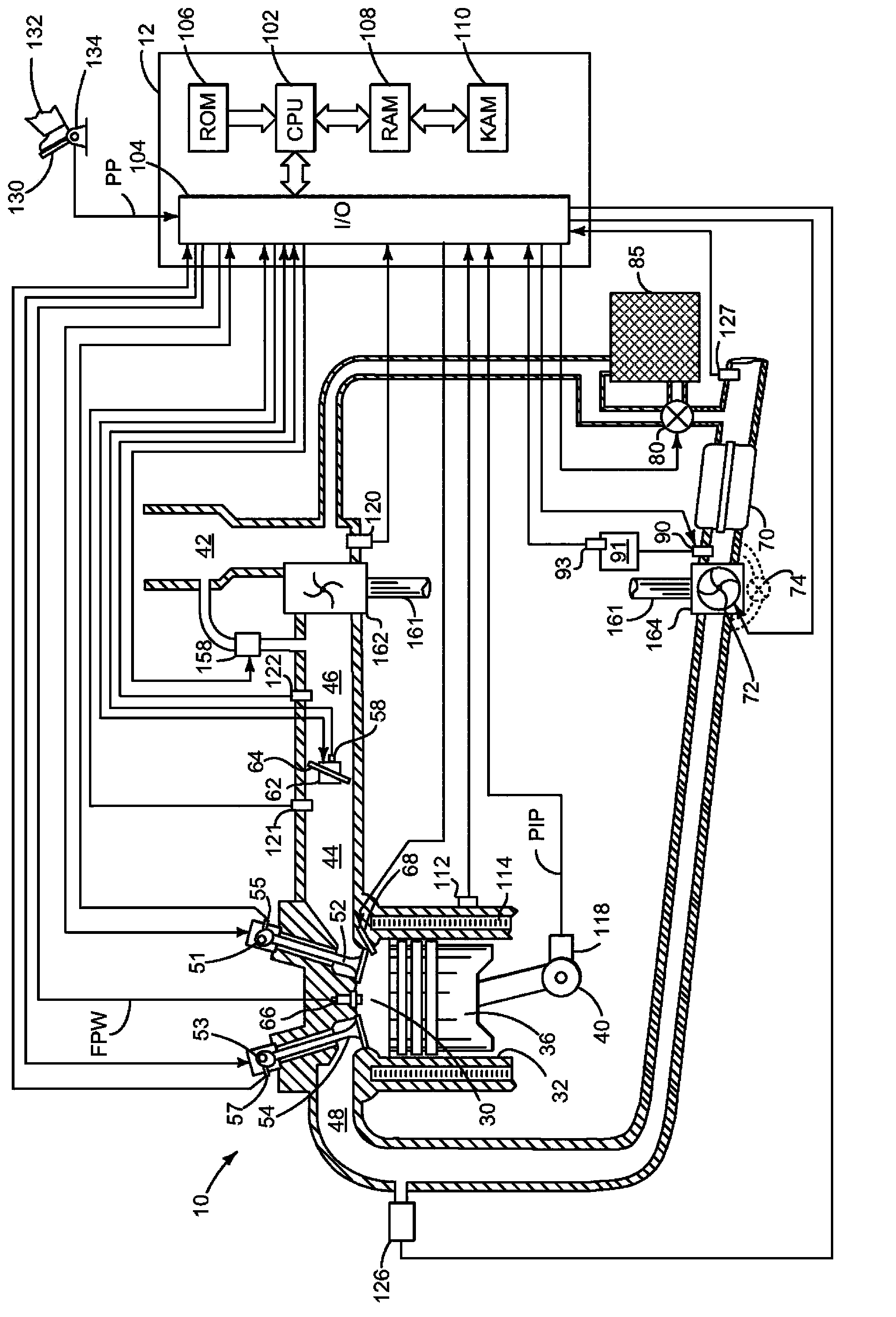

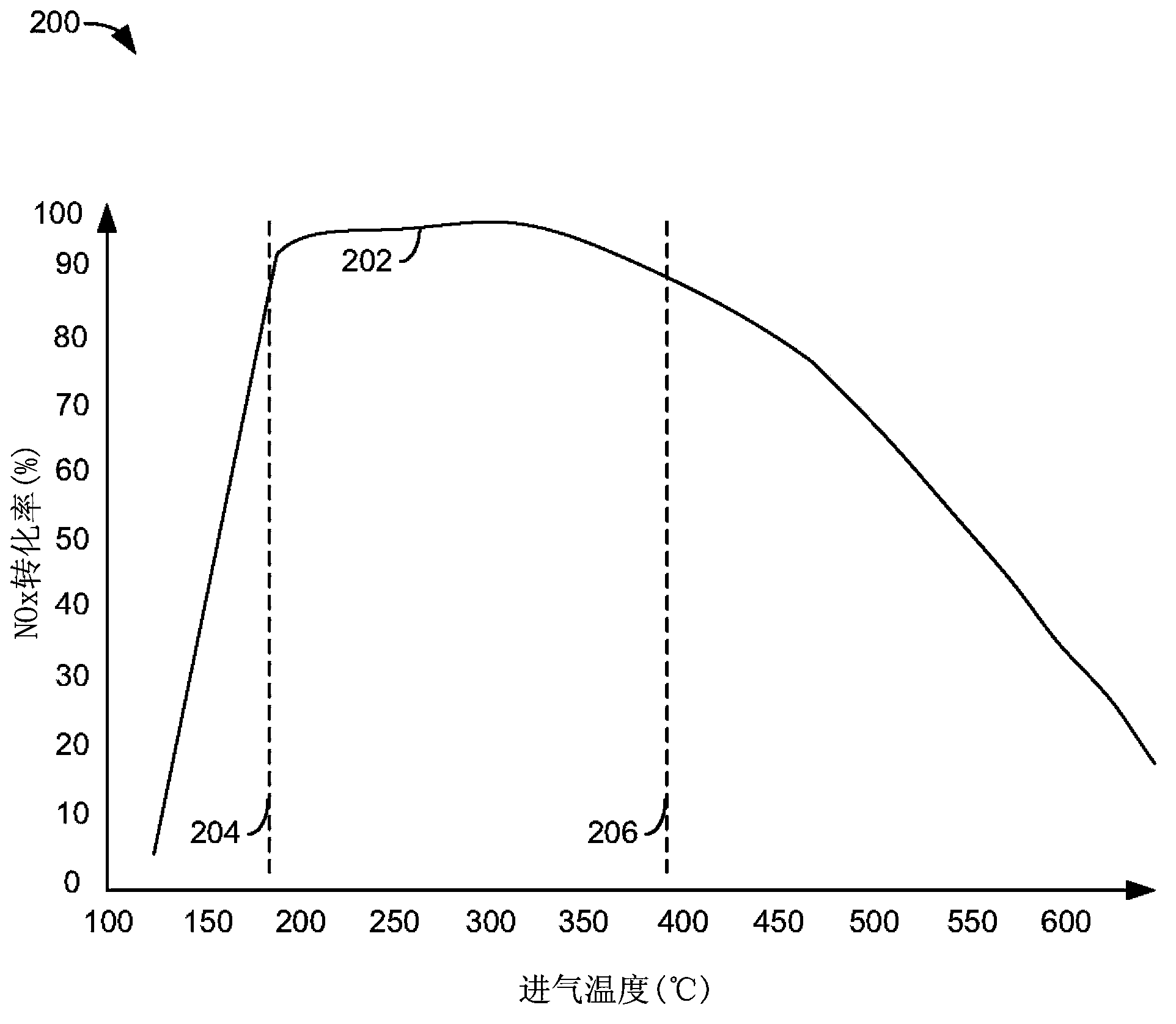

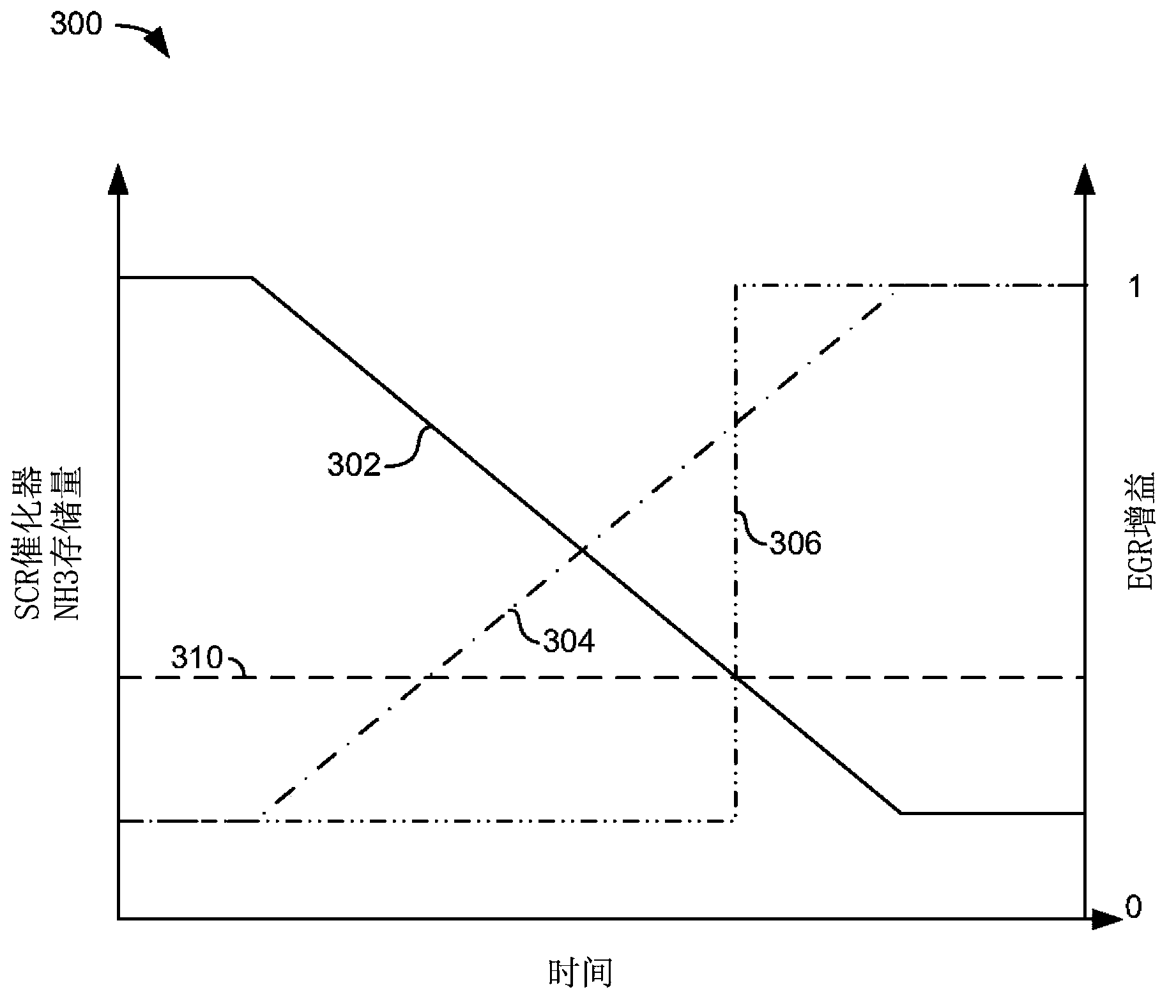

[0024] The present invention relates to improving the fuel economy of vehicles having SCR catalysts. figure 1 An example of a supercharged diesel engine is shown, where when the SCR catalyst is operating in the high-efficiency operating region, Figure 5 The method can adjust the engine operating conditions, thereby reducing fuel consumption. figure 2 An exemplary SCR catalyst conversion efficiency map is shown that identifies a temperature range during engine operation that may reduce engine fuel consumption. image 3 Shown to respond to SCR NH 3 An instance of the manner in which EGR is adjusted is stored. In some instances, the flow of urea to the exhaust system is restricted, thereby reducing Figure 4 Possibility of deposit formation as shown in . Figure 5 A method for reducing engine fuel consumption of an engine including an SCR catalyst is provided. At last, Image 6 shown in which can be applied Figure 5 An exemplary vehicle of the method.

[0025] refer to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com