Cooling system and method of aero-engine

An aero-engine and cooling system technology, which is applied in the cooling of the engine, engine components, turbine/propulsion device, etc., can solve the problems of airflow turbulence obstruction in the external duct, increase the difficulty of design, and increase the adjustable valve, etc., to achieve Reduce the effect of turbulence and obstruction, the effect of propulsion efficiency is small, and the effect of reducing the windward area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

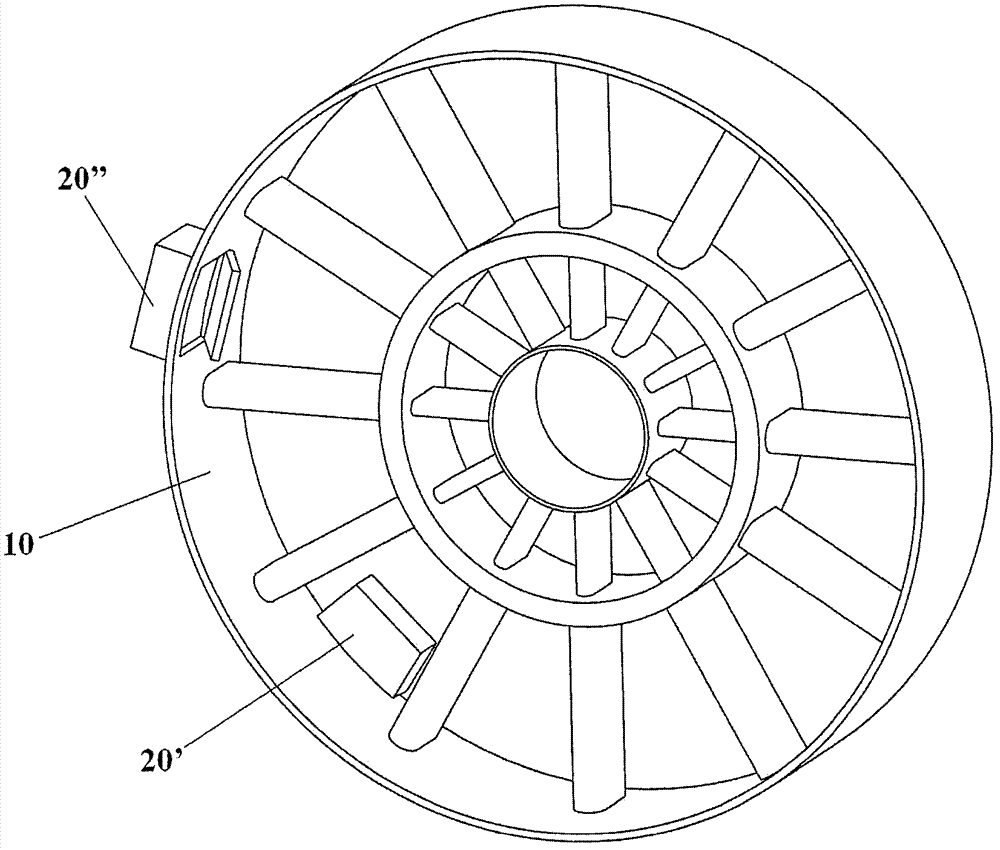

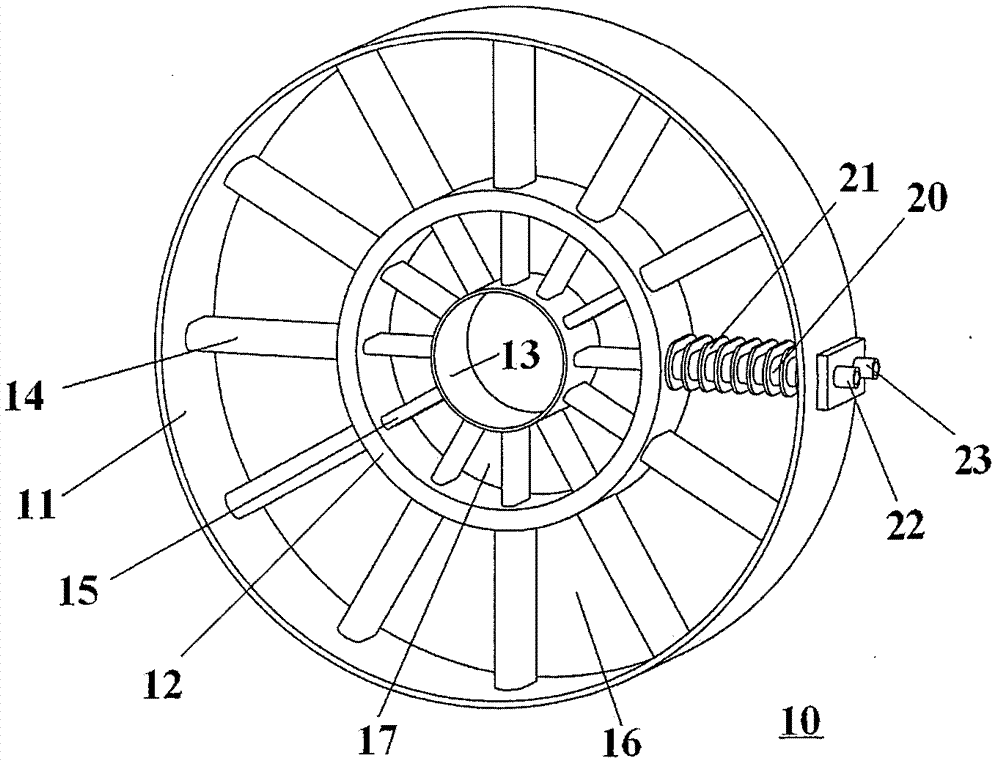

[0036] figure 2 A preferred embodiment according to the invention is shown. The air-lubricating oil cooling system according to the present invention includes an intermediate casing 10, the intermediate casing 10 is composed of an outer ring 11, a middle ring 12 and an inner ring 13, and the middle ring 12 is located between the outer ring 11 and the inner ring 13. The outer ring 11 and the middle ring 12 are connected by an outer stent strut 14 , and the middle ring 12 and the inner ring 13 are connected by an inner strut 15 . Preferably, the number of outer struts 14 and inner struts 15 is the same and their axes are on the same radius. The passage between the outer ring 11 and the middle ring 12 is the outer duct 16 , and the passage between the middle ring 12 and the inner ring 13 is the inner duct 17 . Cool air sucked in by the engine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com