Engine rotating speed control device of rotary drilling rig

A technology for engine speed and control devices, applied in engine control, machine/engine, electrical control, etc., can solve the problems of limited engine power, unscientific use methods, energy waste, etc., to save energy, facilitate analysis of faults, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

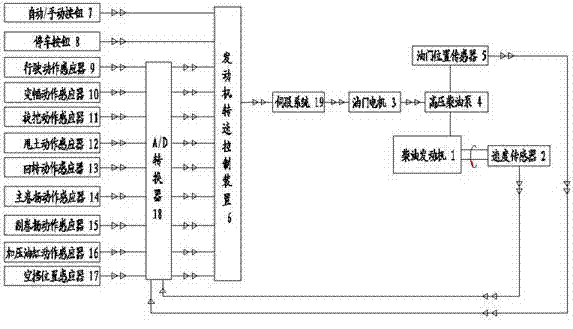

[0011] The invention includes a diesel engine 1, a speed sensor 2, an accelerator motor 3, a high-pressure diesel pump 4, an accelerator position sensor 5, an engine speed control device 6, an automatic / manual button 7, a stop button 8, a driving motion sensor 9, and a variable amplitude action Sensor 10, rotary excavation motion sensor 11, soil throwing motion sensor 12, slewing motion sensor 13, main hoist motion sensor 14, auxiliary hoist motion sensor 15, pressurized oil cylinder motion sensor 16 and neutral position The sensor 17 is connected with the A / D converter 18, and the invention is an engine speed control device 6 equipped with an automatic / manual button 7 and a parking button 8, and the engine speed control device 6 is connected with the A / D converter 18 , A / D converter 18 and driving motion sensor 9, luffing motion sensor 10, rotary digging motion sensor 11, soil throwing motion sensor 12, rotary motion sensor 13, main winch motion sensor 14, auxiliary The winch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com