Method for calibrating sounding balloon bursting instrument and calibration device thereof

A sounding balloon and calibration method technology, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of affecting the effect of inspection, affecting the test efficiency, large errors, etc., and achieve the goal of improving efficiency and testing Accuracy, the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

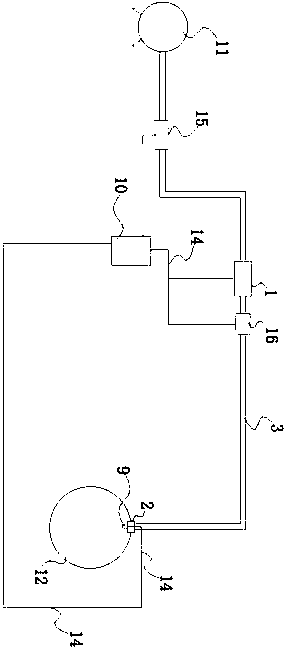

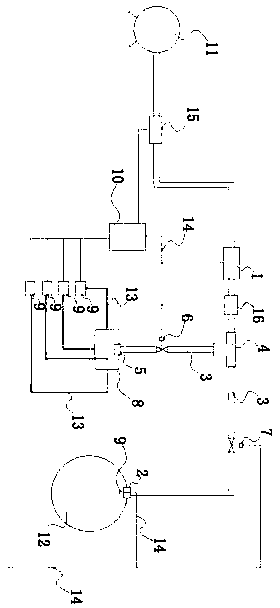

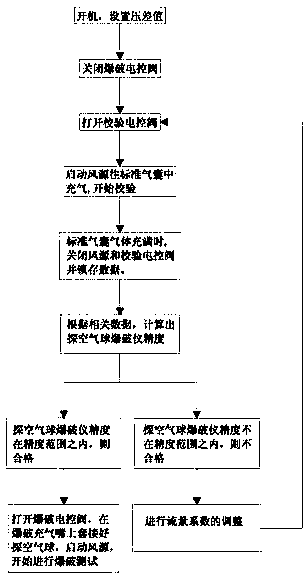

[0027] Example: such as figure 2 As shown, in order to realize the verification method described in the present invention, it is necessary to add a tee 4 on the pipeline 3 between the pressure sensor 16 in the sounding balloon blasting instrument and the blasting inflation nozzle 2, and one end of the tee 4 passes through The pipeline 3 is connected with the pressure sensor 16, and the other end is connected with the blasting inflation nozzle 2 through the pipeline 3, and the remaining end of the tee 4 is connected with the calibration inflation nozzle 5 through the pipeline 3, respectively connecting the three A verification electric control valve 6 and a blasting electric control valve 7 are set on the pipeline 3 between the tee 4 and the calibration charging nozzle 5 and on the pipeline 3 connecting the tee 4 and the blasting inflation nozzle 2. A standard airbag 8 is set on the inflation nozzle 5, and a differential pressure sensor 9 connected to it for detecting the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com