Compensation method for precision deviation of wafer stage of defect observation equipment

A compensation method and defect technology, applied in instruments, semiconductor/solid-state device testing/measurement, measurement devices, etc., can solve problems such as defect image detection efficiency and accuracy discount, achieve real-time compensation, improve stability, and ensure normal production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions in the present invention will be described in conneffled and complete, and embodiments, below, will be described below, as will be described in connection with the accompanying drawings. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without making creative labor are the scope of the present invention.

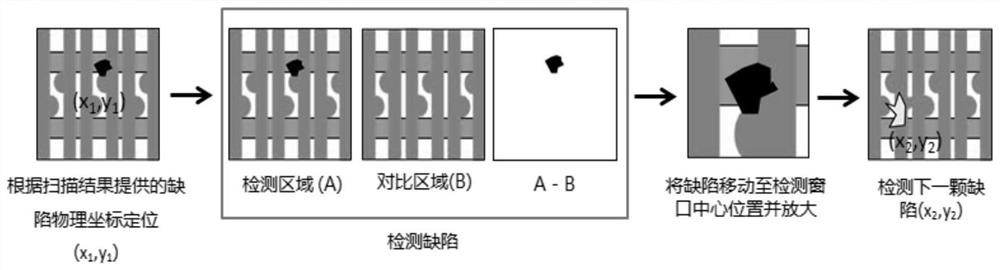

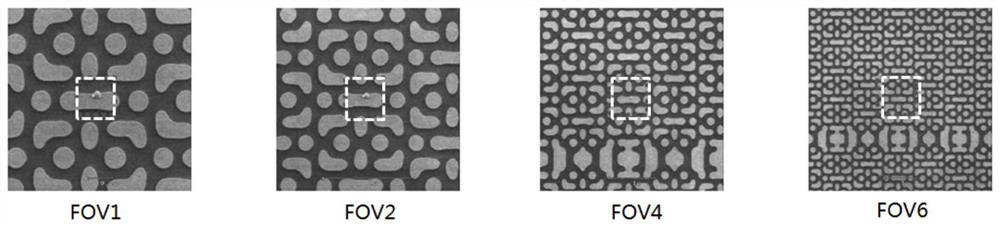

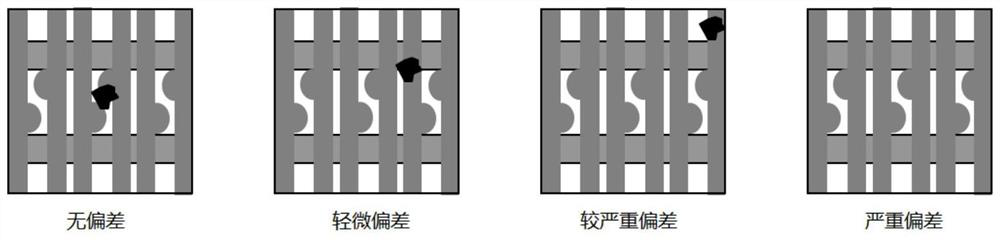

[0031] In the semiconductor chip manufacturing process, the defect detection scanning electron microscope plays an important role in analyzing defects, reducing defects, and raising the improvement. See figure 1 , figure 1 Detect the process diagram of the scanning electron microscope inspection defect for the defect. Such as figure 1 As shown, it is mainly to further accurately defective position by the position of the scan discovery defect, and then enlarges and captures. In the context of the key dimensions of the manufacturing process, the defects that may affect the yield a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com