High-voltage pothead lineation cutting positioning method

A technology of high-voltage cable head and high-voltage cable, which is applied in the direction of cable installation, cable installation device, dismantling/armouring cable equipment, etc., which can solve the problems of difficulty in installation and production, high difficulty in processing, and low accuracy of scribing position. To achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

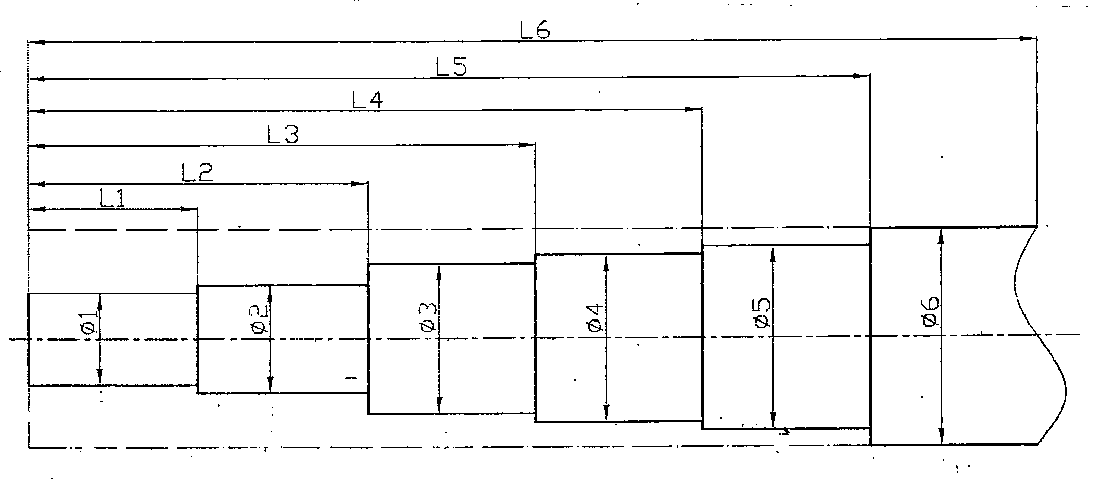

[0018] figure 1 1-6 represent the six layers of high-voltage cables. L1 is the length of the first section to be removed, L2 is the length of the second section to be removed, L3 is the length of the third section to be removed, L4 is the length of the fourth section to be removed, L5 is the length of the fifth section to be removed, L6 is the sixth length to be resected. In order to complete the layered cutting of the above six sections, at present, a tape measure is used to measure one section, and one section is cut off. The present invention can complete the scribing of the above-mentioned multi-layer cutting positions at one time.

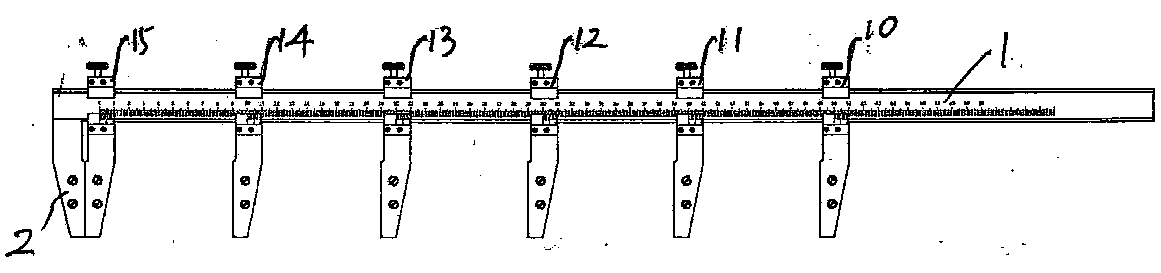

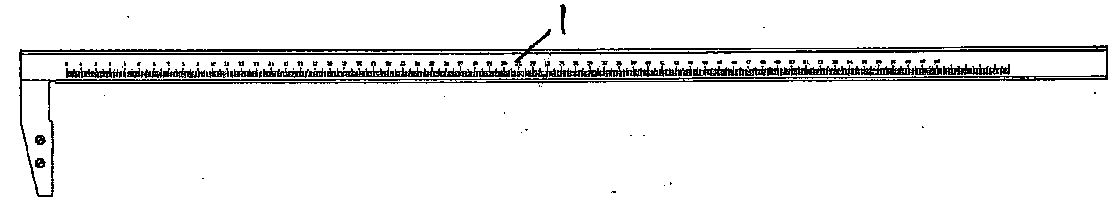

[0019] A high-voltage cable head scribing cutting positioning method, the right end face of the main ruler claw end positioning block of the high-voltage cable head scribing and cutting positioner is facing it with the end of the high-voltage cable to be cut, and the auxiliary ruler snap ring is clamped on the high-voltage cable On the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com