Transmission rotor with buffer function

A rotor and rotor body technology, applied in the direction of electromechanical transmission devices, electric vehicles, electric components, etc., can solve the problems of large noise, large impact, and easy damage to the transmission mechanism, and achieve the effect of low noise and reduced damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

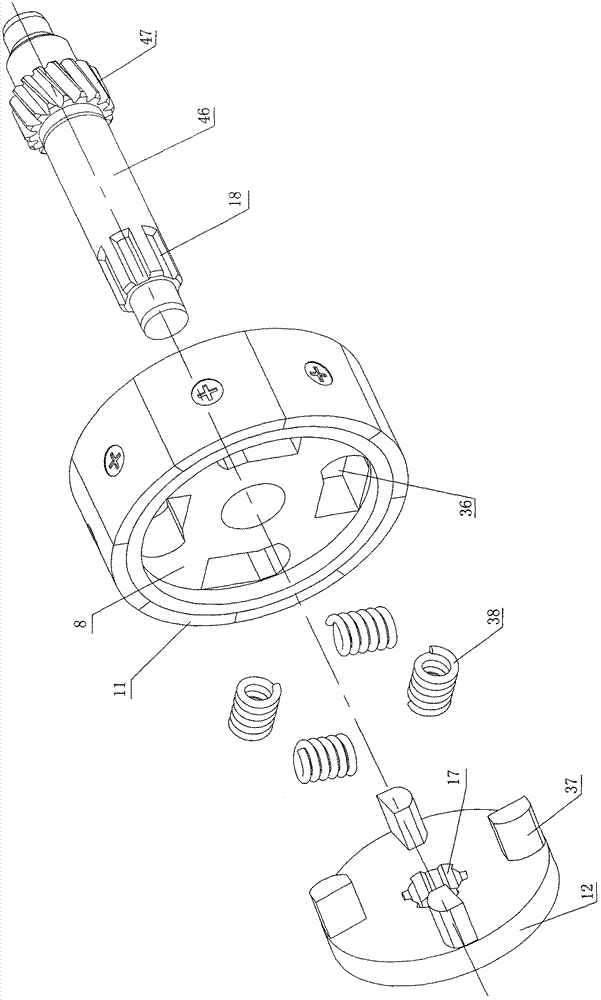

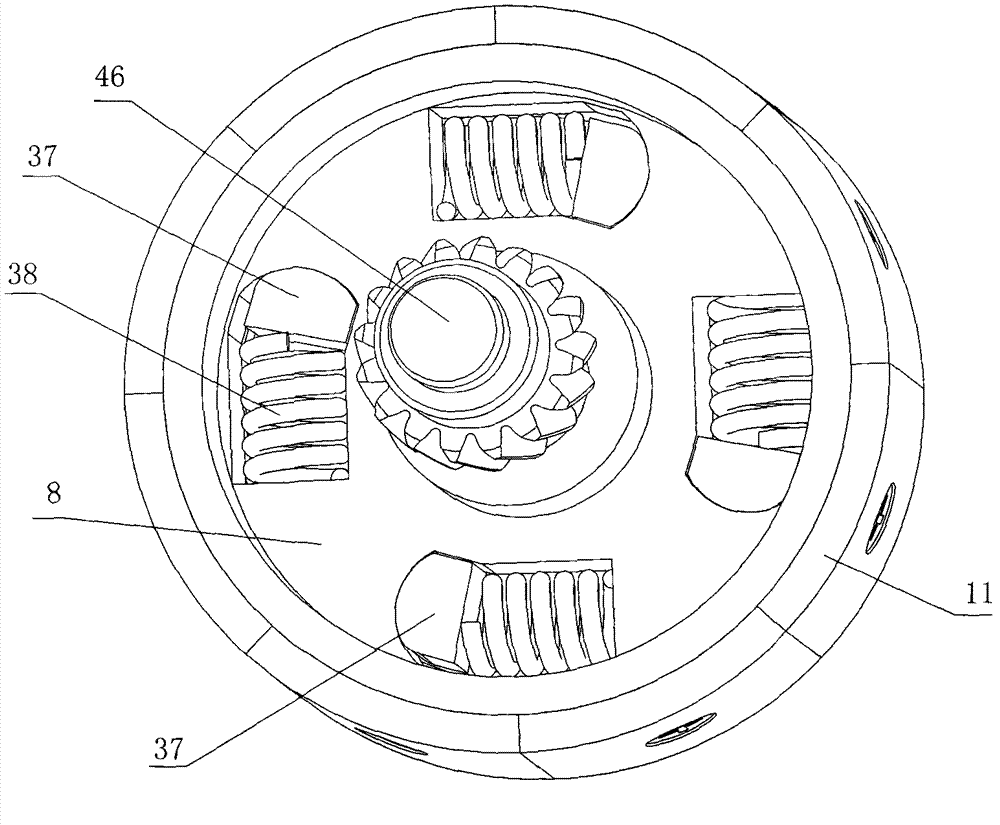

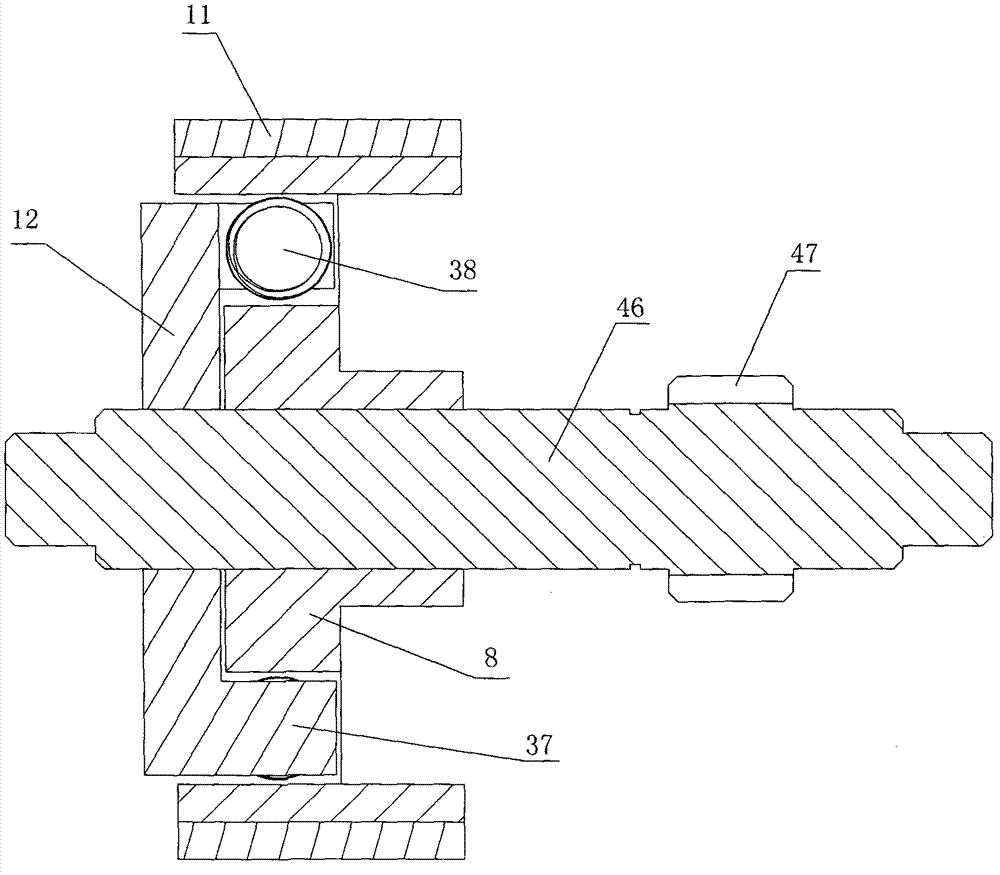

[0016] Such as Figure 1 to Figure 3 As shown, the transmission rotor with a buffer includes a rotor body 8, a groove 36 is provided on the rotor body 8, and the rotor body 8 is sleeved on the motor shaft 46, and the driven block 12 and the boss are connected to the motor shaft 46. Block 37 , the protrusion 37 is inserted into the groove 36 , and the rotor body 8 can rotate on the motor shaft 46 to a limited extent.

[0017] After the motor 3 is energized and rotated, the rotor body 8 drives the driven block 12 to rotate through the damping spring 38 when the rotor body 8 rotates, and the driven block 12 is connected to the motor shaft 46 to rotate.

[0018] When the rotor body 8 rotates, it will first rotate the motor shaft 46 by a certain angle, so that the damping spring 38 in the groove 36 is compressed, and then the driven block 12 is driven to rotate by the damping spring 38, and the driven block 12 is connected to the motor shaft 46 together. Rotate, the power is trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com