Breaker with function of vertical stress decomposing

A vertical pressure and channel technology, applied in the field of medical appliances, can solve the problems of glass slag falling into the bottle body, unfavorable protection of medical staff, splashing outward, etc., to achieve safe and controllable breaking effect, stable breaking process, and avoid lateral vibration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the drawings and specific embodiments.

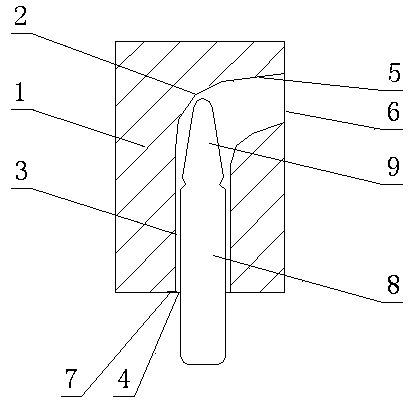

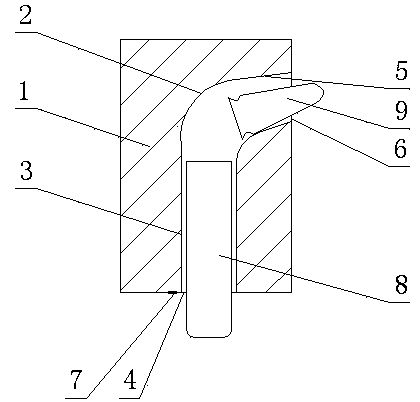

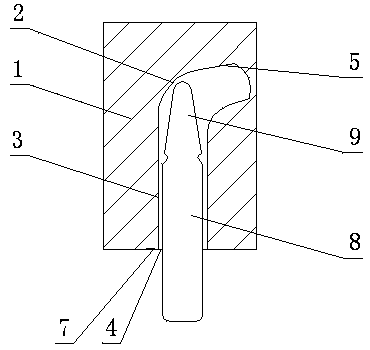

[0023] Such as figure 1 , 2 As shown in, 3 and 4, a breaker capable of decomposing vertical pressure includes a guide member 1, a channel is provided in the guide member 1, and the channel has an inflection point 2 and is divided into two sections by the inflection point. The surface of 1 has an inlet 4, and the length of the inflection point 2 from the inlet 4 is greater than the height of the nipple of the ampoule and less than the height of the ampoule. The curvature of the channel is not less than 90°, that is, the angle formed between one section 3 and the other section 5 of the channel is not less than 90°. The size of the internal cross-section near the inflection point 2 of the channel is greater than the size of the internal cross-section of the rest of the channel, and a vertical downward force is applied to the breaker, which can pass the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Camber | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com