Waste heat recovery device

A waste heat recovery and thermoelectric technology, which is applied to electrical components, generators/motors, etc., can solve the problems of high power system requirements and achieve the effects of wide application scope, energy saving and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

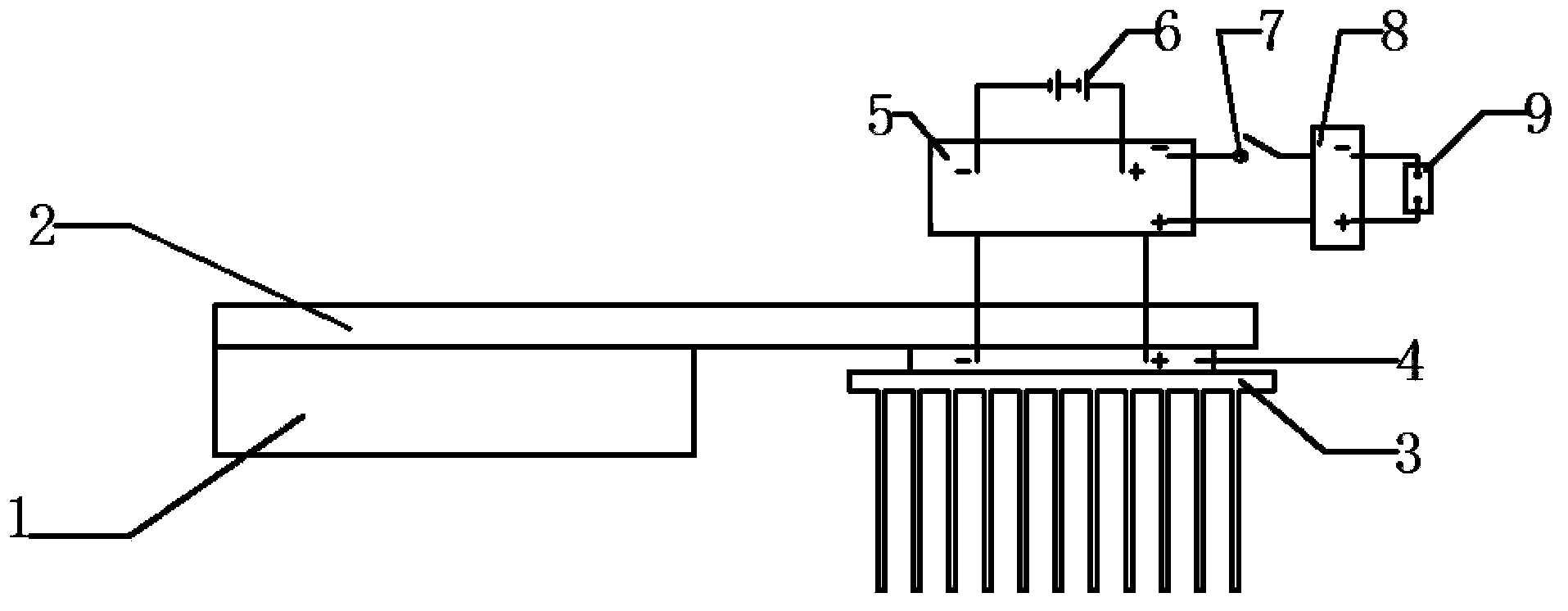

[0023] The waste heat recovery device of the present invention will be further described in detail below in conjunction with the accompanying drawings.

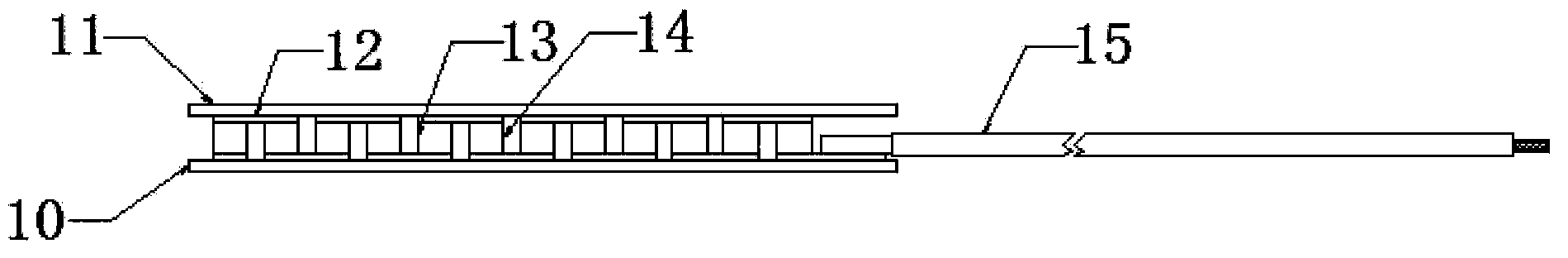

[0024] Such as figure 1 As shown, the waste heat recovery device of the present invention includes: a micro-groove flat heat pipe 2, a cooling fin 3, a thermoelectric power generation sheet 4, a charging protection circuit and a battery 6, and one end of the micro-groove flat heat pipe 2 is attached to the brake heating element 1, The other end of the micro-groove flat heat pipe 2 is in close contact with one side (hot side) of the thermoelectric generator 4, and the heat dissipation fin 3 is installed on the other side (cold side) of the thermoelectric generator 4, and the thermoelectric generator is protected by charging through electrodes The circuit is connected, and the charging protection circuit charges the storage battery 6 . Preferably, the size of the micro-grooved flat heat pipe 2 is 240mm×110mm×20mm, the size of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com