Zinc-based alloy shot

An alloy and zinc-based technology, applied in metal processing equipment, manufacturing tools, transportation and packaging, etc., can solve the problems of time-consuming spray processing, black spots, low sensitivity of dust cloud explosion, etc., to achieve longer life, suppress wear, suppress The effect of reducing toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0053] Hereinafter, evaluation tests performed to confirm the effects of the present invention will be described.

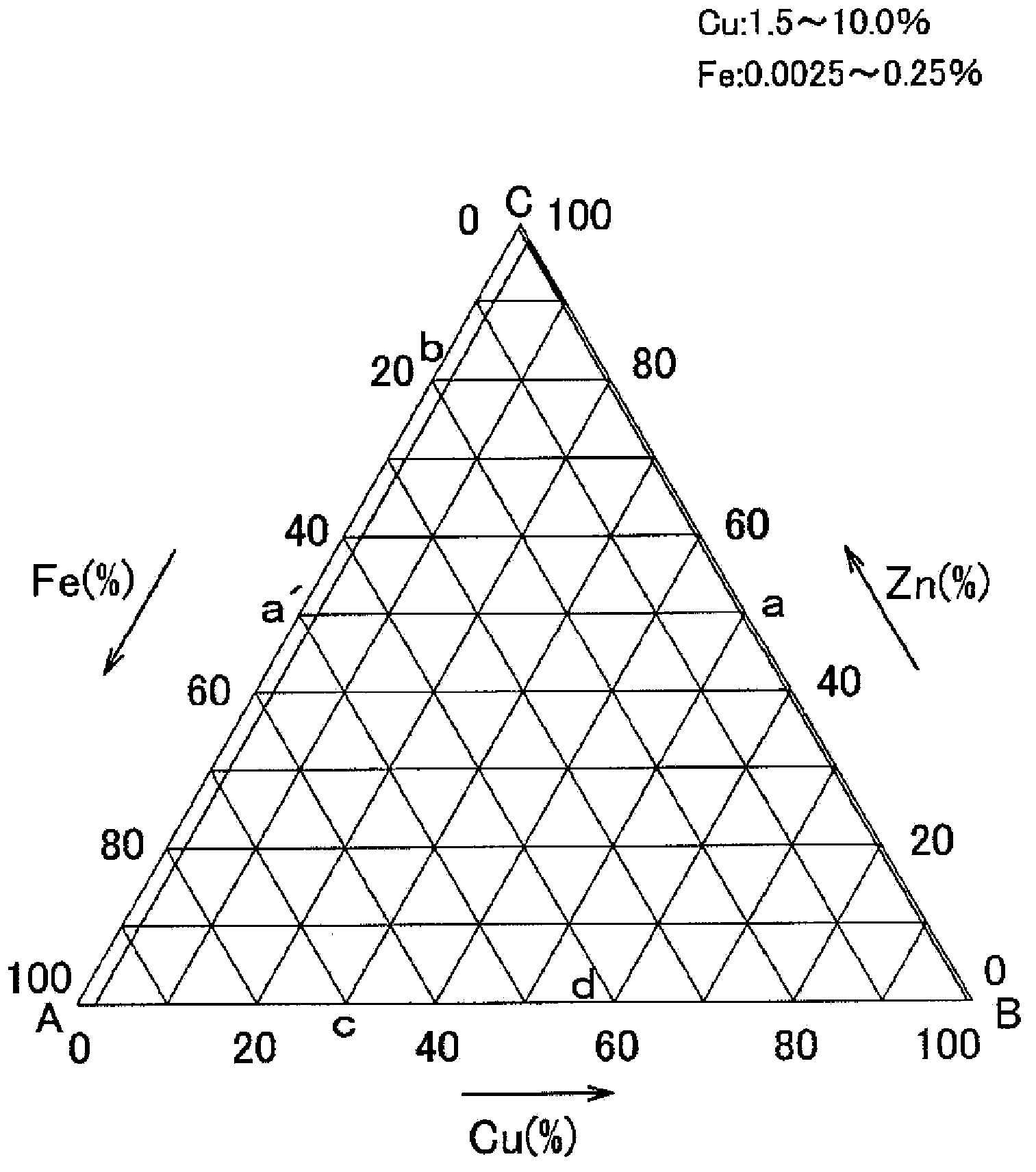

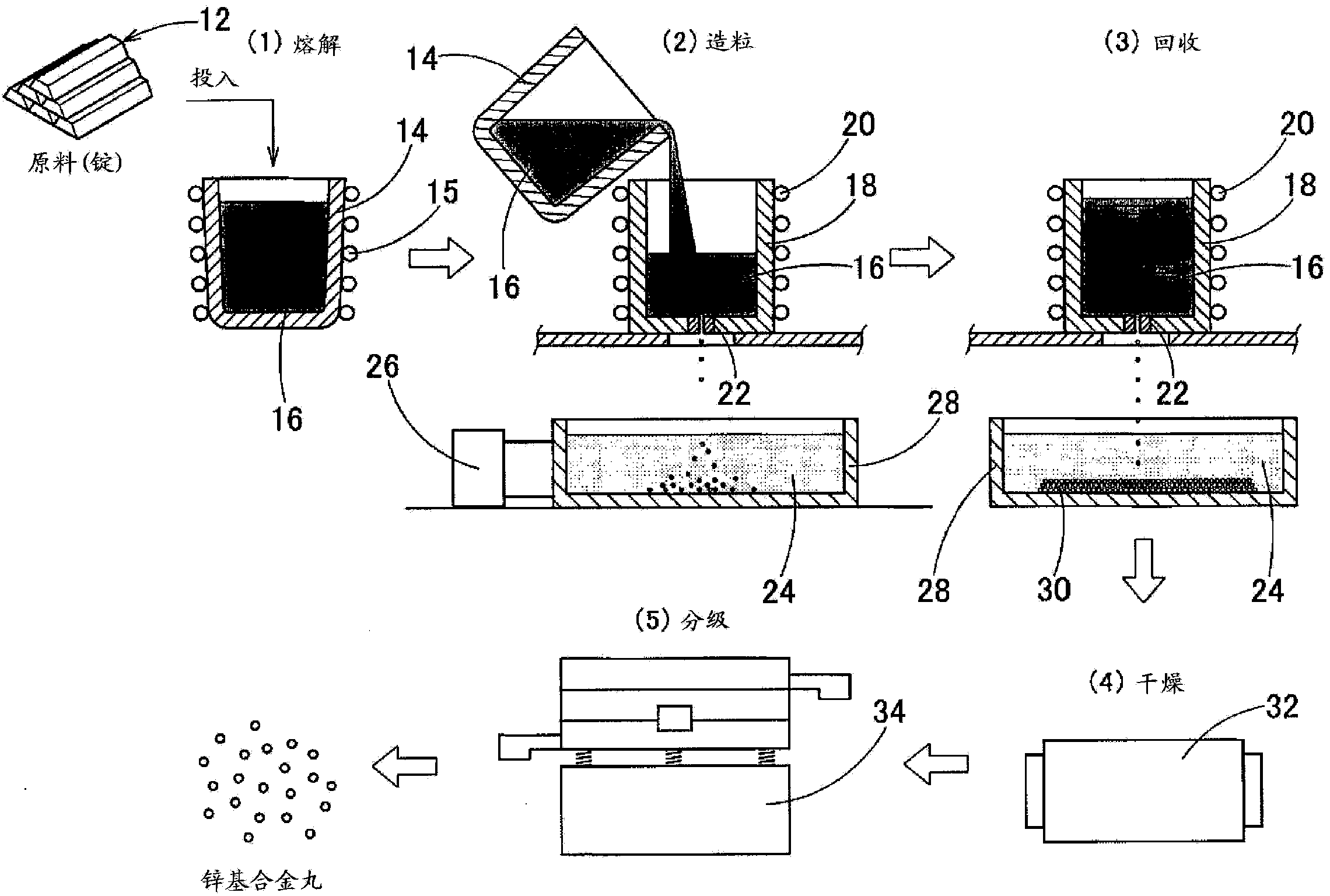

[0054] The manufacture of each zinc-based alloy shot is to utilize the aforementioned figure 2 The method shown (droplet granulation method) was carried out so that the alloy composition was as shown in Table 1. The pellets produced in this way were classified to prepare projection pellets for each sample having an average particle diameter (median particle diameter) of 1.0 mm. In addition, the following experiments were performed on the pellets of each sample, and the evaluation was performed.

[0055] [Table 1]

[0056]

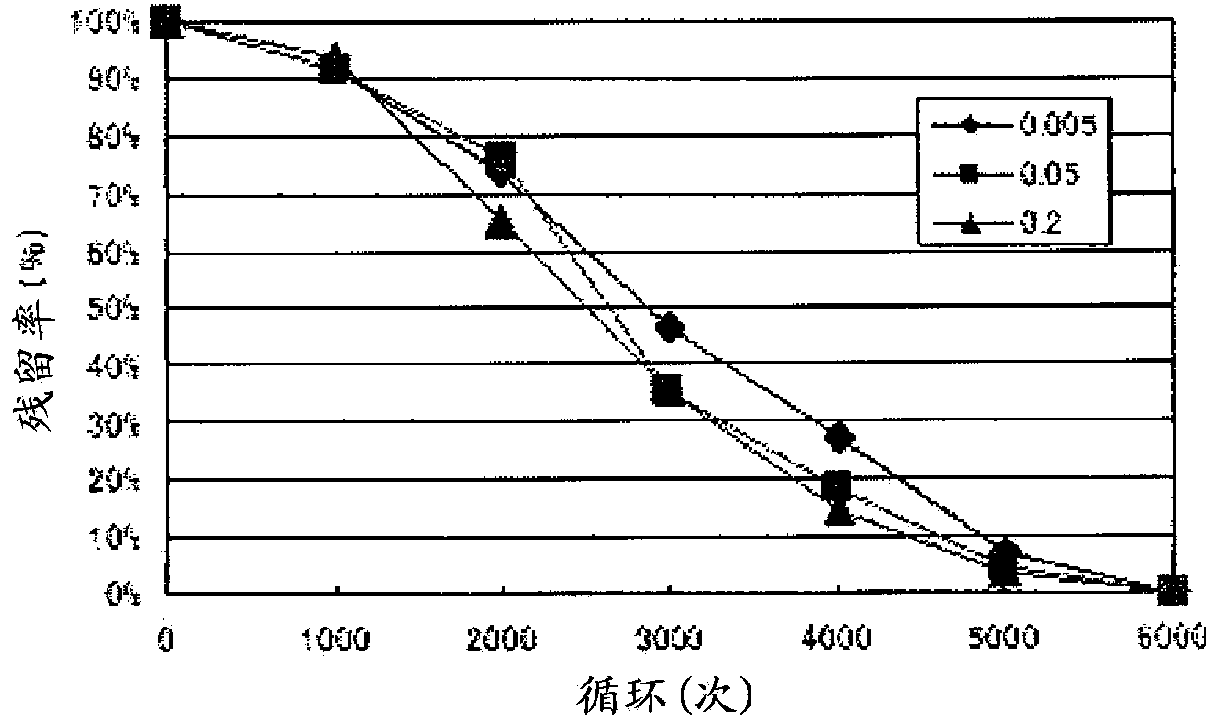

[0057] 1) Shot peening evaluation experiment

[0058] 100 kg of pellets (average particle diameter 1.0 mm) of each sample prepared above were shot at a target steel material (Rockwell hardness 65 HRC (according to JIS G0202, JIS G0202, JIS Z2245 stipulates)) projection (launch) 5000 times.

[0059] 1) Vickers hardness

[0060] For ea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com