Conveying device for packaged air conditioner rear board processing

A technology of conveying device and air conditioner, applied in the directions of transportation, packaging, roller table, etc., can solve the problems of distortion and deformation of the rear plate, poor working environment, scratches on the surface of the rear plate, etc., to reduce vibration and collision, reduce production costs, No scratches and scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below with reference to the accompanying drawings and examples. It should be noted that, in the case of no conflict, the following embodiments and features in the embodiments can be combined with each other.

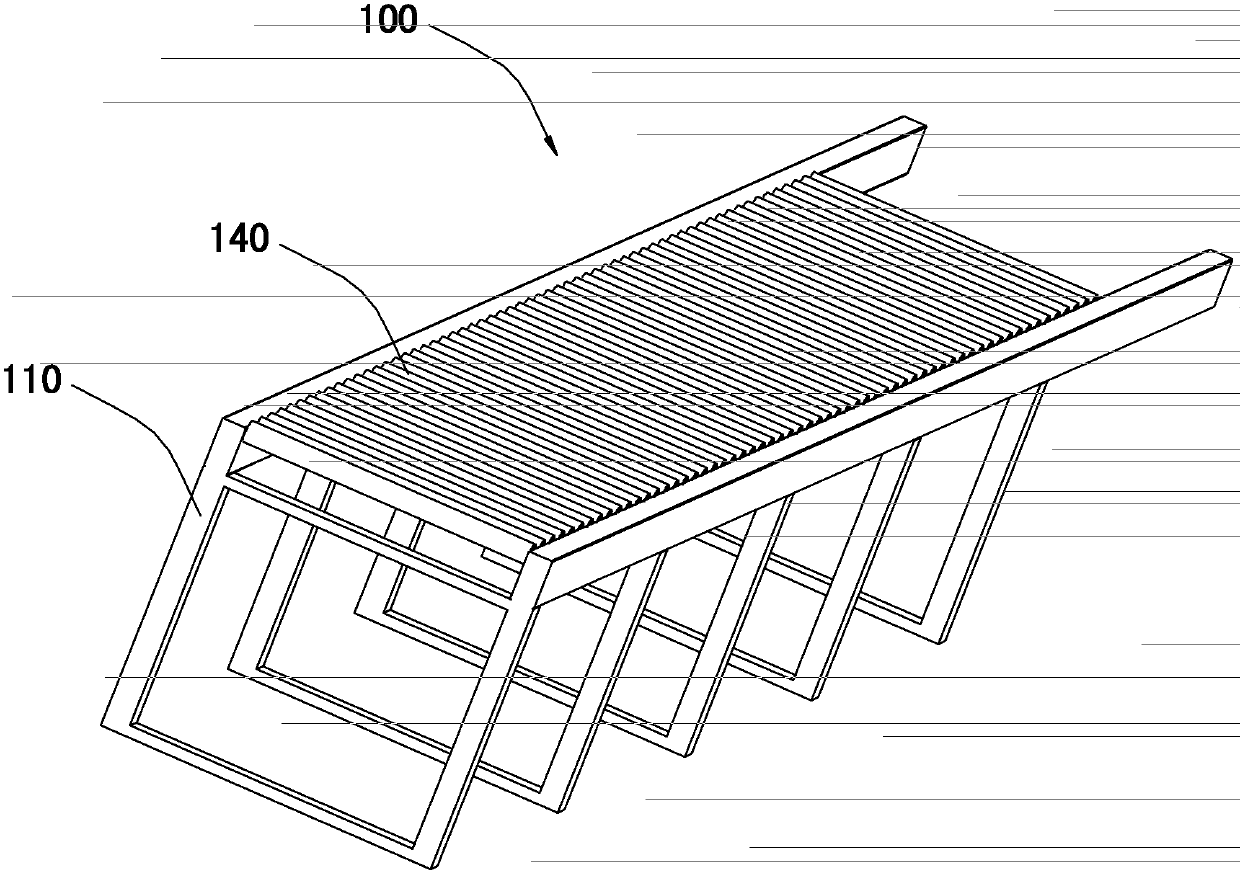

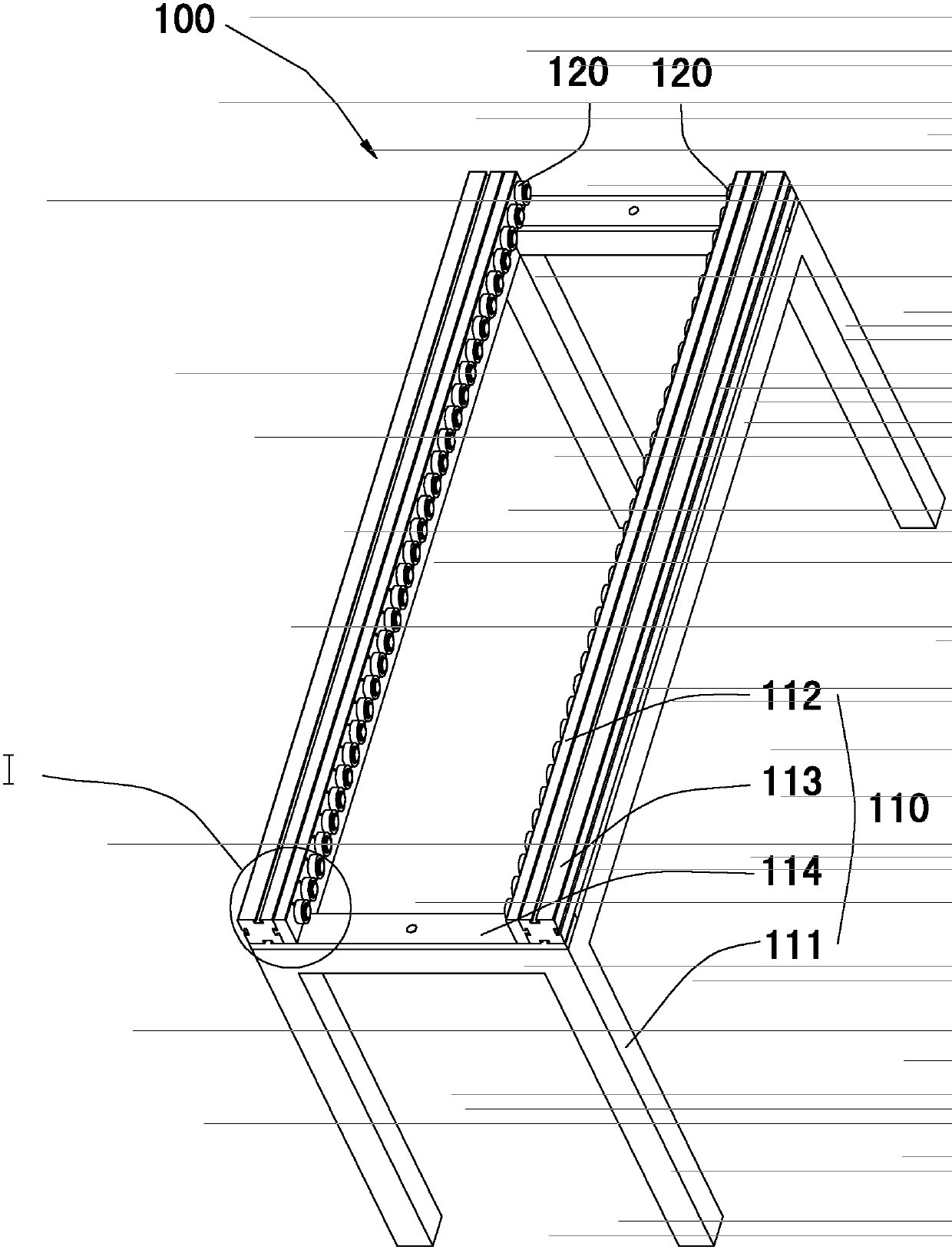

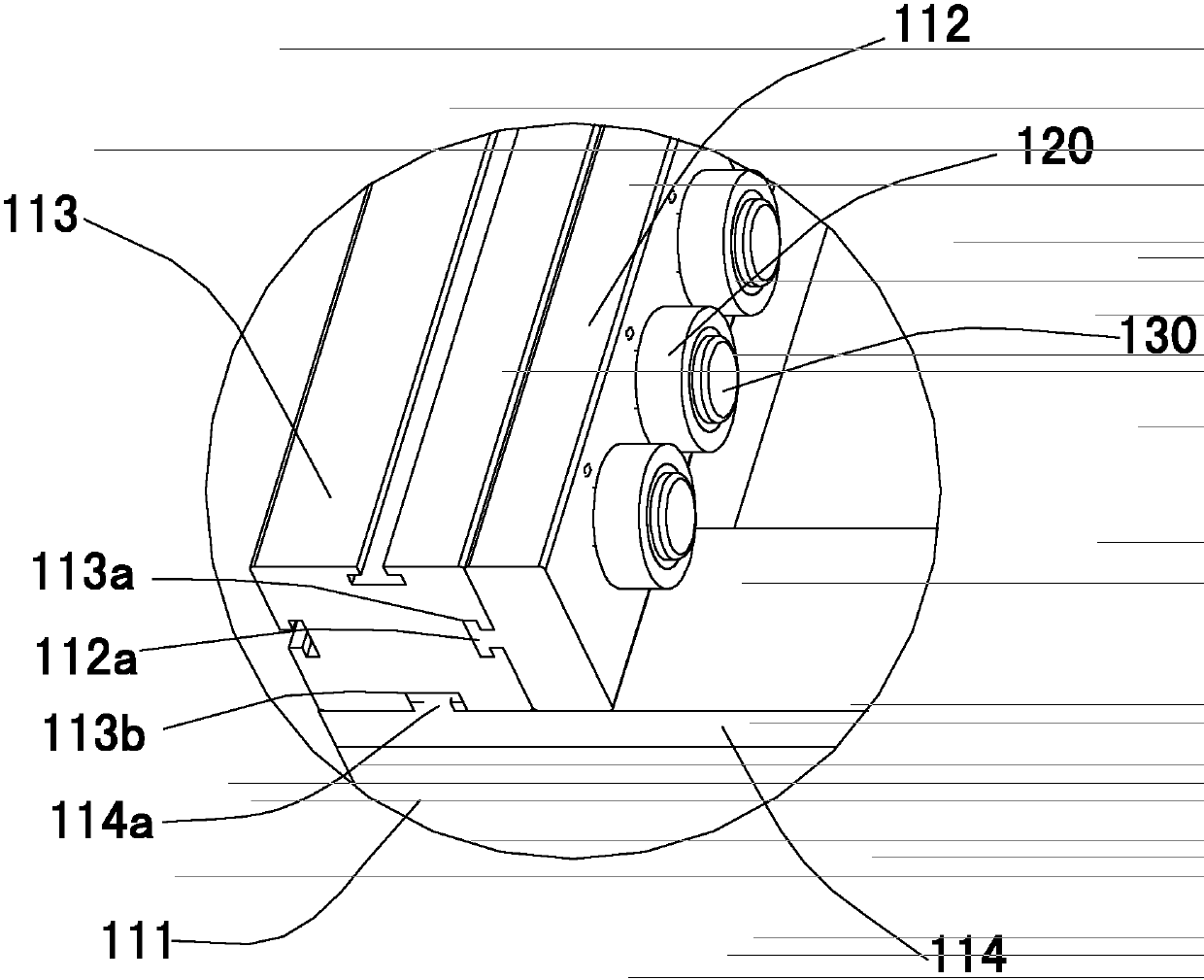

[0028] see figure 2 and image 3 As shown, the conveying device 100 for back panel processing of a cabinet-type air conditioner in one embodiment of the present invention includes a frame 110 and two rows of rear panel support conveyors arranged on the frame 110 along the rear panel conveying direction. 120 , the distance between the two rows of rear board supporting conveying parts 120 is smaller than the distance between the two flanges 210 in the width direction of the rear board 200 .

[0029] The process of using the conveying device 100 of the embodiment of the present invention to convey the back plate 200 is as follows Figure 4 and Figure 5 As shown, the rear panel 200 is conveyed in an undercut mann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com